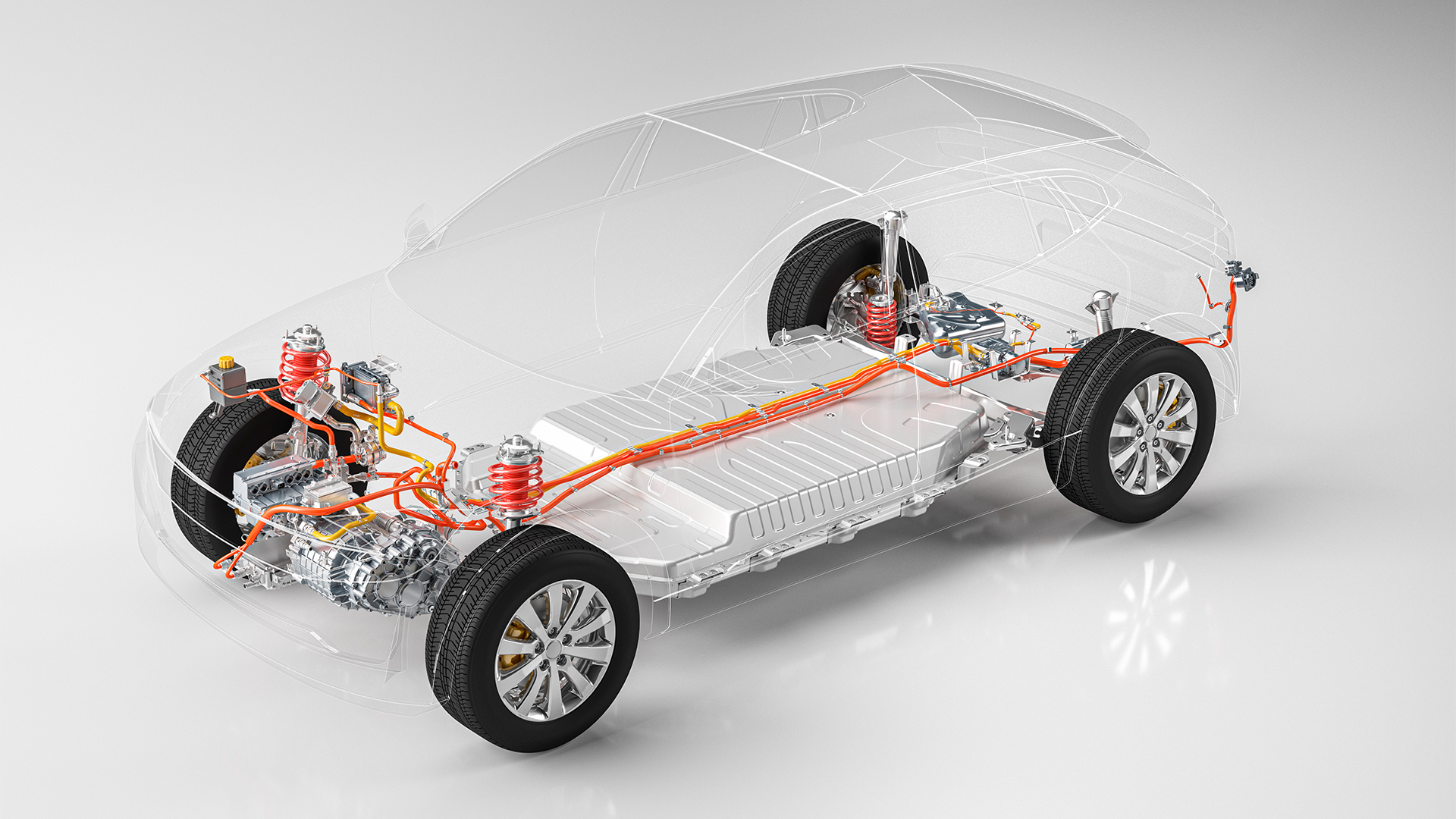

New vehicle designs, especially EVs, are far from traditional vehicle designs and must be ready to meet evolving regulations. Acoustic challenges arise from the need for interior sound packages to meet brand, weight, and noise comfort specifications. An accurate and early assessment of noise contributions from sources such as powertrain, air induction, and exhaust systems iskey for the accurate prediction of interior noise.

By using ESI's Virtual Proving Ground for Acoustic Performance, engineers create a pleasant journey with superior sound quality by removing undesired interior and exterior noise - fully digital: From excitation to sound radiation, and through different transmission paths, virtually test the acoustic performance of your car’s design. Work in a virtual test track to get new designs right the first time while eliminating costly physical prototype tests for sound quality analyses.

Simulate Interior Noise and NVH

Create a pleasant journey with superior sound quality by removing undesired interior and exterior noise. Work in a virtual test track to get new designs right the first time while eliminating physical prototype tests for sound quality analyses.

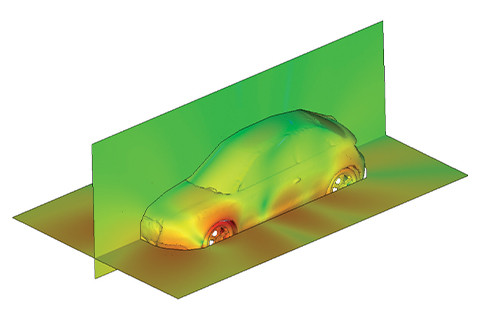

Simulate Exterior Acoustics

Don’t compromise on safety. Realize a world without traffic fatalities by creating effective acoustic warning systems that protect vulnerable road users in EV traffic. Meet regulations for pass-by-noise right the first time.

How to achieve an optimal acoustic experience for electric vehicles?

Today, it is possible to create a pleasant journey with superior sound quality and predict any undesired interior and exterior noise fully virtually. Organizations like Audi, Bentley, Nissan, and the US Army are already harnessing the convenience of a digital vehicle test facility.

Read our new e-book to

- gain insights into the latest advancements in EV acoustics engineering

- discover how VA-One can revolutionize your approach to testing and development.

Achieve optimal acoustic performance in every aspect of your electric vehicle design with the VA-One simulation software

Watch the webinar on demand and find out how you can deliver electric vehicles that not only prioritize sustainability - but also excel in acoustic performance.

You will learn more about 5 key features of VA-One, acoustic simulation software, empowering EV manufacturers to meet their acoustics performance targets for electric vehicles including: Pass-by Noise, Acoustic Vehicle Alerting System (AVAS), Sound Package Design and Optimization, Wind Noise and Auralization.

By using Virtual Prototyping, Bentley succeeded in what we set out to do –optimize every component of the Flying Spur firstly in the virtual world before we create physical parts. At the same time, we have reduced physical prototypes, creating the quietest in-cabin experience for our customers. Virtual Prototyping means fewer prototypes have to be built, and we reduce our testing mileage. It also helps influence the design and engineering of the car at an early stage and affords significant benefits in the extensive testing phase.

Simon NobleBentley Motors

Addressing Interior & Exterior Noise

Remove any undesired noises from the vehicle’s interior early, optimize individualized sound zones for a truly enjoyable auditory experience, and meet the regulatory and performance targets for exterior noise right the first time.