Virtual Design, Test, and Qualification of Aerospace Components and Structures

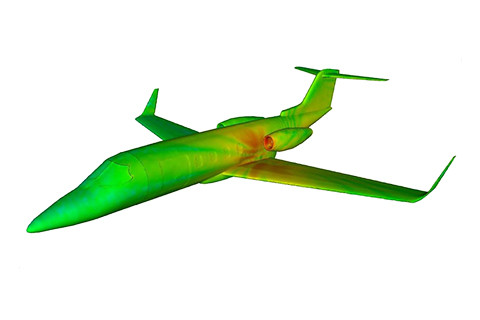

Noise is a key brand differentiator in the aeronautic sector, and a critical mission success factor in space applications where constructors and operators are focused on improving operating performance and sustainability.

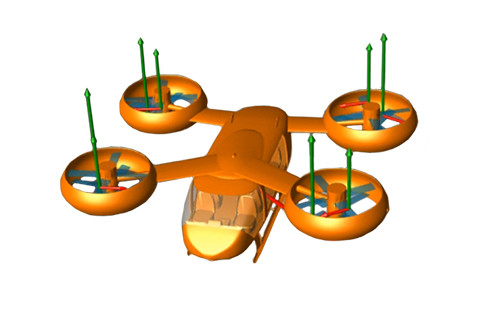

When trying to optimize the weight vs. cost ratio to meet interior noise targets of aircrafts, helicopters and new air mobility, engineers can run into delays and cost overruns in the design cycle. Challenges also arise mainly from the qualification of vibro-acoustic performance of sensitive payloads in the space industry.

To meet demanding design objectives, acoustic engineers must be able to assess and accurately predict acoustic problems like noise and vibration of new designs early in the design cycle before committing to expensive physical prototype testing.

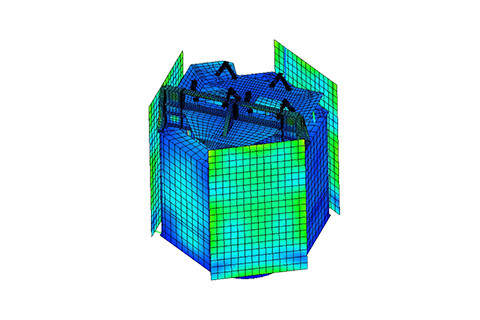

Build Your Very Own Virtual Acoustic Chamber to Test Noise

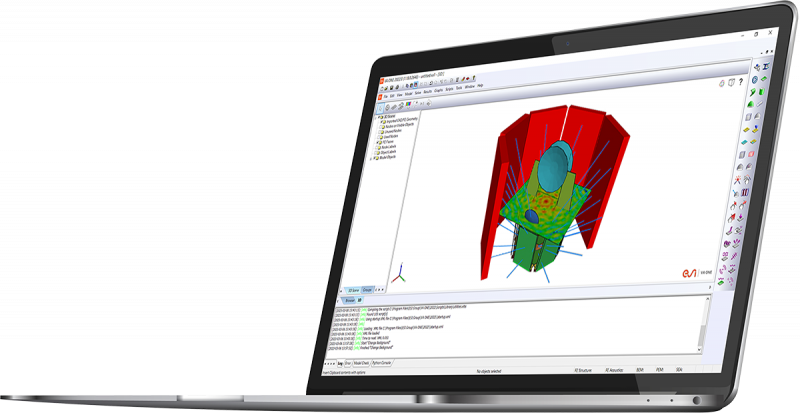

The use of virtual prototyping and vibro-acoustic analysis and simulation software is being adopted by engineers as a proven solution to overcome design challenges whilst still meeting regulatory constraints.

With ESI’s Acoustic Performance solution, users can virtually test space structures using an in-house virtual acoustic chamber that avoids the need to move sensitive equipment to remote facilities.

By using VA One, engineers are able to emulate the diffuse acoustic field on both fairing and payload using strategically placed loudspeakers calibrated to provide meaningful test results in a laboratory environment that remove the need to use expensive, high energy test facilities.

Users can accurately analyse all vibro-acoustic performance criteria simultaneously and deliver precise individual and overall results.

For a fraction of the time and cost compared to physical prototyping, engineers can:

- Run numerous aero-vibro acoustic trials for various configurations early in the design phase

- Optimize and fine-tune performance simultaneously to ensure design objectives are achieved

- Virtually qualify structures before committing to expensive physical prototypes

ESI has been a fantastic partner in helping Joby develop a first-of-its-kind vibro-acoustic model of an eVTOL aircraft,”

Greg GoetchiusLead Engineer for Noise and Vibration at Joby Aviation

What is Vibroacoustic Analysis and Performance Simulation And How Can it Transform Your Engineering Projects?

Discover the game-changing potential of advanced vibroacoustic simulation techniques with this comprehensive eBook: Silent (R)Evolution - How Vibroacoustic Performance Simulation Accelerates Innovation in Ground, Air, and Space Vehicles.

Inside, you will see how to efficiently run virtual aero-vibroacoustic analyses to...

- Unlock Innovation and Optimize Workflows.

- Reduce Costs and Improve Accuracy.

- Ensure Space Mission Success.

- Enhance Passenger Comfort.

- Accelerate vehicle design, testing, and development.

- Exceed Vibration Performance Expectations.