VA ONE

Interior Acoustics Modeling and Simulation Software

In the scope of their virtual prototyping activities, leading automotive and aerospace companies rely on ESI’s vibroacoustic simulation software VA One to meet design goals for interior and exterior acoustic performance arising from both structural (i.e: road noise) to aeroacoustic (flow-induced) excitation.

VA One empowers designers to optimize products by making informed trade-offs of material choices related to acoustic performance, comfort, cost, and weight.

Whether new mobility solutions use electric, combustion, hybrid, or hydrogen power, whatever the design and material choices engineers make, the acoustic experience inside a vehicle or aircraft is a key differentiator defined by brand objectives.

VA One provides engineers with an all-in-one solution, a unique software environment, to understand the impact of design and material choices on final acoustic comfort.

- Full library of material models, physical properties & subsystems provides highly accurate noise predictions ensuring early confidence in compliance with noise regulation standards

- Single development environment for product validation reduces the training need for multiple tools

Achieve Your Interior Acoustic Performance Targets Using VA One

VA One gives engineers the ability to assess vibroacoustic performance across the full-frequency range using the Finite Element Method (FEM), Boundary Element Method (BEM), or Statistical Energy Analysis (SEA) for structure-borne and airborne noise alike. Here are a few examples showing how engineering teams can successfully manage interior noise with VA One, creating a pleasant sound for the human ear.

Opt for One of the Best Software For Acoustic Analysis of Automotive Interior Noise

In the automotive industry, the influence of trim components on acoustic comfort is an important brand-related consideration conditioned by concerns including weight, cost, and overall acoustic performance. Additional challenges arise from the accurate assessment of noise contributions from sources such as engine noise, tires, powertrain, induction, and exhaust systems, which are key for the accurate prediction of interior noise. In the past, this assessment was performed using expensive acoustic test cells that relied on the availability of prototype hardware, which arrived late in the design cycle.

Supporting concurrent engineering, VA One delivers accurate results in early design stages, reducing the need for costly rework.

- Trim optimization: create models to collaboratively identify optimal interior noise performance

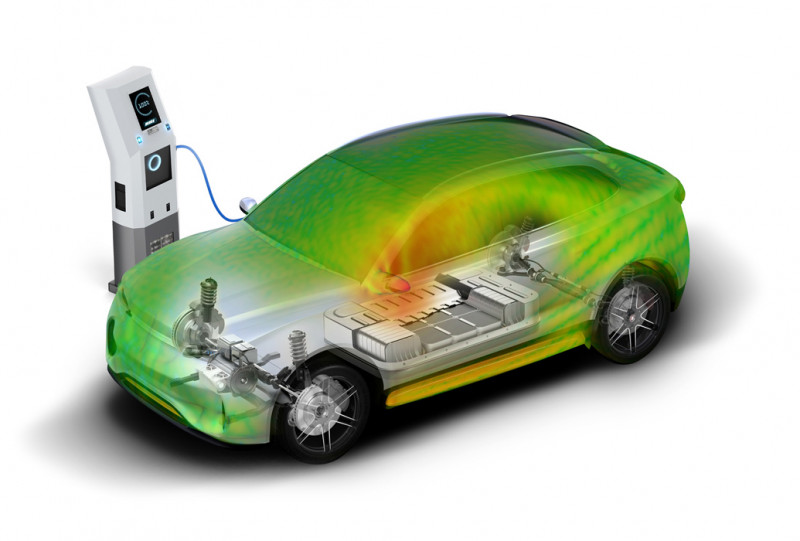

- Tackle EV-related challenges including new transmission paths and sources

- Speech Clarity and Infotainment: Optimize infotainment systems for enhanced Speech Clarity

- Reduce Buzz, Squeak, and Rattle (BSR) by identifying operating contacts in sub-assemblies and evaluating their sound intensity early on to avoid expensive recalls during the service life of the product

- Powertrain noise: compute and analyze noise transfer paths from the source to the receiver to establish countermeasures to reduce structural energy transmission

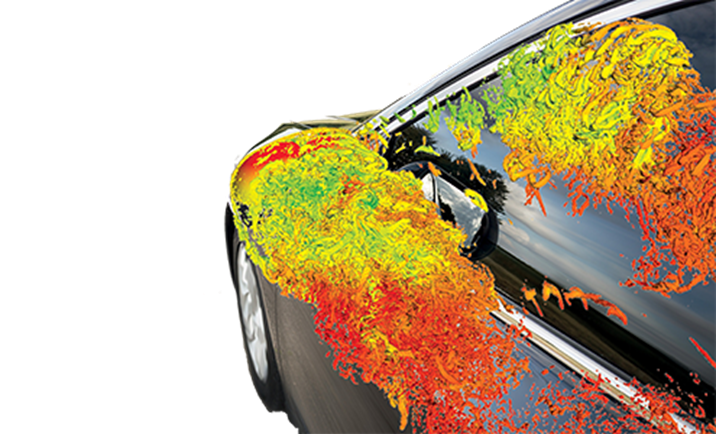

Wind Noise: Deliver accurate Aeroacoustics Noise Prediction (AVA)

The absence of the internal combustion engine and associated ancillary equipment makes wind noise a major source of interior noise in Electric Vehicles. VA One provides an accurate cost-effective simulation solution to reduce the use of scarce, expensive, and time-consuming for information gathering in wind tunnel studies.

- Easily couple Computational-Fluid Dynamics (CFD) time history data with your VA One model

- Use any third-party CFD code as an input source, including open-source codes like OpenFOAM

- Use multiple excitation sources: both experimental and CFD sources can be used to define aero-acoustic excitation

- Use General Surface Pressure (GSP) to establish CFD load cases

- Benefit from Wave Number Analysis for load visualization

- Full-frequency acoustic predictions: noise transmission can be modeled using low-frequency deterministic tools of high-frequency Statistical Energy Analysis

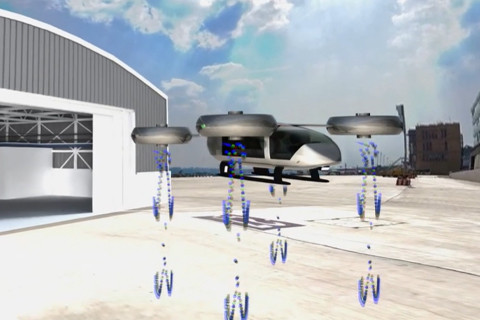

Aircraft Interiors: Achieve Optimum Cabin Noise and Comfort for All Aircraft Applications

Whether you are working on the development of a new passenger jet, helicopter, eVTOL, or any other type of aircraft for commercial or military applications, VA One will support you in reaching your goals while balancing constraints for interior noise & comfort. The precise evaluation of acoustic comfort levels for multiple design alternatives, provided early in the design cycle, enables acousticians to innovate whilst limiting the risk of additional costs and delays caused by late redesigns.

VA One enables aerospace engineers to virtually test cabins and cockpits to ensure they reach desired levels of passenger comfort:

- Deliver sound insulation designed to meet noise and weight targets

- Offer individualized thermal comfort and passenger sound space

- Predict wind noise and develop countermeasures

- Test speech clarity for cockpit and cabin alike

- Identify noise contributors

- Find optimum countermeasures

- Design suitable trim packages

- Glazing

Discover How Joby Aviation Uses VA One to Meet Their Interior Acoustic Performance Goals

ESI has been a fantastic partner in helping Joby develop a first-of-its-kind vibro-acoustic model of an eVTOL aircraft,”

Greg Goetchius

In his presentation from ESI LIVE 2022, Greg Goetchius, Lead Engineer for Noise & Vibration at Joby Aviation, shared a case study about the company’s product development activities, from noise reduction to interior and exterior acoustic performance.

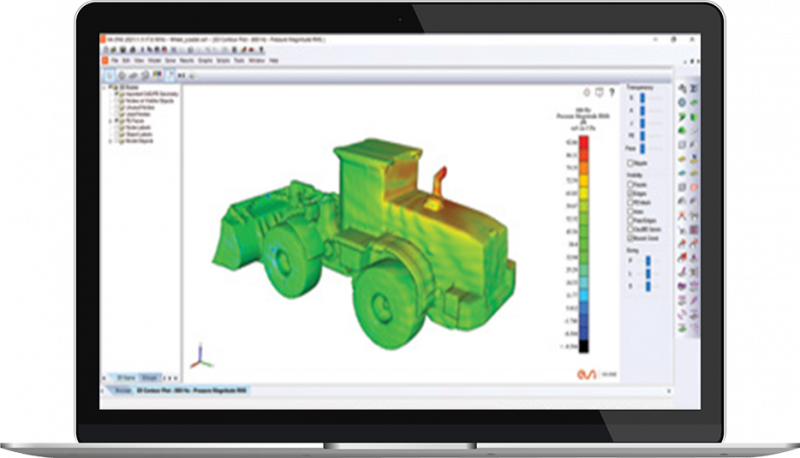

Heavy Machinery: Perform Cabin Noise Simulation as You Would on a Virtual Proving Ground

Engineering safe, clean, and productive heavy machinery or equipment without having access to the actual product or production prototype is a major design challenge. What if you could gain access to a Virtual Proving Ground to test cabin noise and operator acoustic comfort early on, before the design freezes? Using VA One, you can ensure operator comfort and meet interior noise regulations:

- Model in a single software environment across the full frequency spectrum using FE /Hybrid/ SEA method

- Start from a CAD/ FEA import

- Build model geometry including beams, cavities, shells, and Semi-Infinite Fluids (SIF)

- Populate your database with physical properties/ DLF/ sound package

- Define flanking paths (including pass-throughs, and leaks) and noise sources (road, tires, wind noise...)

- Account for airborne and structure-borne noise sources