How can you be certain your product will be safe and easy for workers to operate?

How do you ensure desired levels of process feasibility, ergonomics, worker safety, accessibility, visibility, and operability?

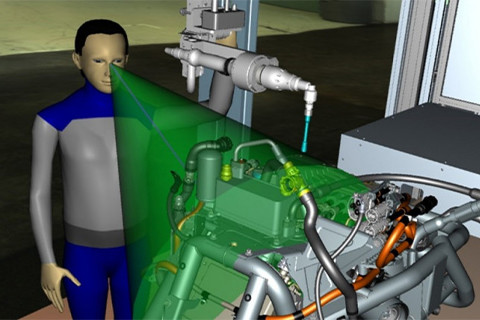

Product integration and design for ergonomic human operation can be tested early, safely, and fully virtually using ESI’s Virtual Reality (VR) solution to ensure product operation will be both safe and productive.

How can you use VR for Human-Centric Process Validation and Product Integration?

Delivering “true-to-life” human-centric process and products evaluations, our VR software solution enables engineering teams to evaluate decisions early in product development, when design changes can still be made without incurring dramatic costs or delays. This way, heavy machinery companies like Volvo Group Trucks Technology affirm their sustainability goals by freeing themselves from physical mock-ups, whilst avoiding late surprises in production. In addition, the immersive virtual environment also enables collaborative and concurrent engineering and a way to experience, validate and communicate on design decisions throughout every step of product development.

Think of the roadblocks you can avoid if you want to reduce design iterations: VISIBILITY | Find out early enough if designs create blind spots for operators. Reachability | Will diverse operators are able to easily adjust mirrors? Or replace parts? Accessibility | How easy will it be for your operator to access what is needed?

Witness how XR is reshaping product integration and human-centric process validation

See it to believe it! Join our upcoming digital XR Event on-demand to see how global design leaders at Jaguar Land Rover, Cummins Power Systems and Volvo CE successfully accelerate their transformation from Physical to Virtual to fast-forward innovation and sustainability.

- Hear how XR is reshaping product integration and human-centric process validation

- See how and why companies use mixed reality to accelerate virtual validation and trust

- Understand how to achieve lead time, cost, and downtime reduction targets of your product development by using immersive technologies

- Learn how you too can enable collaboration between globally distributed team members & suppliers for optimal cross-functional team performance

Validate Assembly Line & Assembly Cell Processes with Confidence

When can you evaluate the number of operators that are required for a given operation? Where do you prove how much space will be needed? How to you evaluate the required process time?

Plan your assembly operations early and safely, without requiring any physical mock-up. ESI’s digital human models, or manikins, representing the anthropometry of your choice will let you evaluate ergonomics, operator visibility, reachability, and accessibility to ensure safe and efficient assembly processes, well ahead of production.

Using realistic physics in the immersive world, engineering teams also validate tooling with early confidence. They anticipate cell layout and optimization and make sure they reach their deadlines for the start of production and ramp-up phases.

Anticipate Maintenance and Service Processes

Sustainability is key for today’s heavy machinery products. Extending product life and making sure maintenance and servicing operations will be safe and productive has become a priority for operating companies and OEMs alike.

How can you make sure to deliver on this front before you reach the construction site? Especially for highly innovative products using the latest technologies for which there is no available feedback from the field?

Engineering teams rely on our immersive reality capabilities to evaluate and validate maintenance and servicing processes, well ahead of production, when it is still possible to make design changes without jeopardizing the whole ROI of their product development project.

With IC.IDO, our Virtual Reality software, you will be able to evaluate all aspects of operator comfort, safety, but also efficiency. Once a scene exists, it will take almost no time to put on your VR glasses to validate procedures and processes with physically realistic handling of collisions between parts and obstructed installation/removal paths.

Ensure Smooth Product Integration

When can you effectively validate decisions related to product integration? Where can you experience products before you commit to building them? How do you know your product is properly designed for assembly, service, and operations?

In virtual reality, engineers validate their product integration strategies early on, before any physical mock-up is constructed, so they can define their designs agilely, with minimum impact on cost and delays. Our Virtual Reality solution supports the digital evaluation of packaging and space claim, mechanism design, and interaction, whether for the product in operation or to evaluate assembly, service, and maintenance processes.

Thanks to realistic physics, engineers simulate the behavior of wiring, cabling, and hoses, on a real scale and in real-time, empowering teams to discover issues with tangling, binding, or pinching of hoses and wires to avoid interference, collision, or abrasion in operation.

Check out our web section on building your very own Virtual Proving Ground to see how ESI can help you test and certify products as they will be operated, including operational safety, electrical systems, and durability concerns for all use & misuse cases.