Worldwide

Previously, product development required iteration through numerous prototypes, proof tools, mock-ups, and pre-production builds to identify product design issues or discover challenges for assembly or maintenance workers. Interacting with products during product development escalates human factors issues or ergonomics risks that would otherwise not emerge until the Start of Production, when it is too late to resolve—due to cost, delivery timelines, quality, or safety.

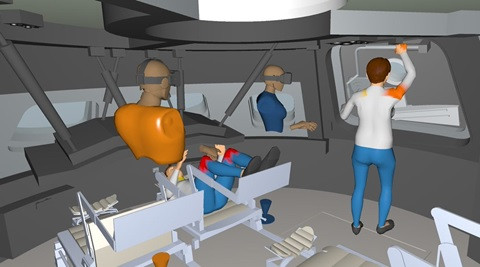

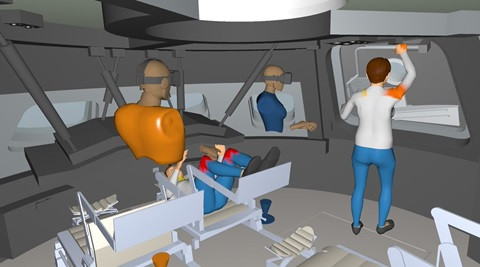

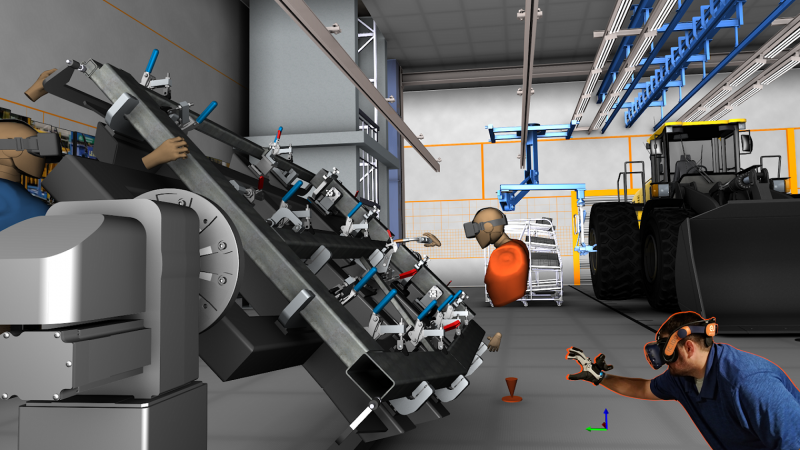

Digital transformation preempts physical build with computer modeling and simulation; eliminating physical build and mock-up construction means people might not install, remove, operate, or otherwise experience the new product in the context of human-centric processes until production launch. Performing Virtual Build, Virtual Service or Maintenance, and other immersive product reviews in the context of human-centric processes, production-intent tooling, and production operators can provide similarly, and potentially better, feedback as builds with physical prototypes and mock-ups.

Our upcoming series of webinars will explore how leading enterprises effectively transcend time and space to collaborate in virtual environments. Where they experience first-hand assembly processes, product operation, and service maintenance operations weeks, months, and sometimes years before physical products are available or even advisable to produce.

XR Webinar Series

Virtual Product Design & Integration Validation | On-Demand

Early Assembly Process & Cell Validation Virtually | On-Demand

Anticipate Maintenance and Service Processes to Ensure Smooth Product Integration | On-Demand

Virtual Product Design & Integration Validation

ACCESSIBLE ON-DEMAND

When can you effectively validate decisions related to product integration? Where can you experience products before you commit to building them? How do you know your product is properly designed for assembly, service, and operations?

In virtual reality, engineers validate their product integration strategies early on, before any physical mock-up is constructed, so they can define their designs agilely, with minimum impact on cost and delays. With Virtual Reality, support the digital evaluation of packaging and space claim, mechanism design, and interaction, whether for the product in operation or to evaluate assembly, service, and maintenance processes.

- With realistic physics, engineers simulate the behavior of wiring, cabling, and hoses, on a real scale and in real-time

- Empower teams to discover issues with tangling, binding, or pinching of hoses and wires to avoid interference, collision, or abrasion in operation

Watch our webinar where we take a closer look at the application of Virtual and Extended reality to perform tests and certify products as they will be operated, including operational safety, electrical systems, and durability concerns for all use & misuse cases.

Access the On-Demand

Early Assembly Process & Cell Validation Virtually

AVAILABLE ON-DEMAND

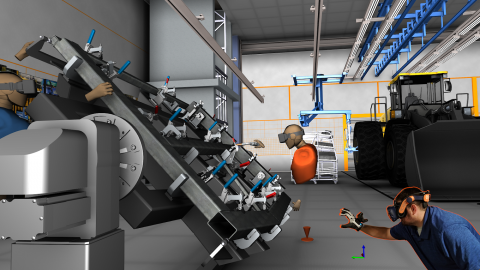

Manufacturing capital goods and long-life products that roll, float, or fly, that can be safely and sustainably produced, operated, and maintained by human beings is not a trivial matter. Computer-aided design tools and digital engineering methods aim to identify manufacturability constraints, predict material performance, and deterministically analyze the manufacturing requirements of the design.

However, adjacent to the products themselves, there are additional considerations like tooling, part/component logistics racks or kitting, part conveyance, and assembly cells or lines. The complexity of large-scale assembly processes is an engineering challenge as significant as designing the product itself. After all, it matters not how great a product is, when it cannot be produced sustainably.

Access the On-demand session where we discuss the virtual validation of human-performed assembly processes.

Access the On-Demand

Anticipate Maintenance and Service Processes to Ensure Smooth Product Integration

AVAILABLE ON-DEMAND

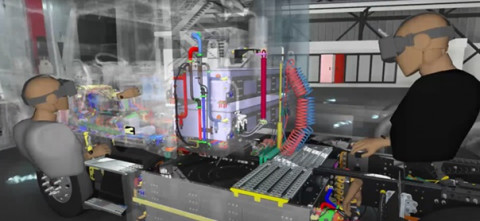

When eXtended Reality, XR, is discussed for service and maintenance, one of the first topics that come to mind is the use of Augmented Reality (AR) devices serving digital work instructions or real-time state reports. AR can overlay 3D views and work instructions onto real-world views, which is a tremendous value to enterprises the world over. However, where do those instructions come from and how did the authors validate them?

Conventionally, maintenance and service processes would be evaluated using pre-production prototypes and physical mock-ups constructed during product development. With digital transformation:

- Reduce or eliminate physical builds,

- Mitigate risk that digital work instructions defined at launch might be incomplete, create new risks, or be impossible to perform

Watch as we look up to the addressable challenges in effective Maintenance Repair Organization planning and dig deeper into the service of long-life off-highway heavy machinery.