Successfully managing global energy supply is crucial to all infrastructures and the maintenance of society worldwide. Energy production and distribution involve many industries whose main challenges today revolve around productivity, continuity, safety, and reliability.

Our customers in the Energy and Power sector face a number of continuously evolving challenges that range from addressing safety, environmental and sustainability issues to managing financial risks and tighter technical requirements. Companies have to comply with increasingly complex regulatory requirements and improving operational performance. Addressing these issues relies on ad-hoc engineering modeling methodologies that must accurately tackle operational and accidental events applicable to the production and transportation installations. Therefore, effective realistic modeling is paramount to staying competitive. Effective realistic modeling calls for a high level of innovation.

Virtual Prototyping Solutions for the Energy Industry

Those, who create and supply energy are facing a complex puzzle: pursue innovation and risk disruption, or cling onto processes that are running smoothly but don’t match today’s expectations? Will the venture into digitalization turn into proven value and ROI? Well-aware of these challenges, ESI’s commitment is to help manufacturers and operators of energy technology, from conventional sources to renewable ones, implement the right digital tools that empower them to innovate and operate efficiently with confidence.

Manufacturers, distributors, and suppliers in the energy field use ESI’s solution for an ‘as-built’ and ‘as-operated’ modeling of equipment for the evaluation of performance, the optimization of maintenance plans, and the dismantling of obsolete installations. From Oil & Gas to nuclear and windmills, with over 30 years of experience in the energy field, ESI's extensive suite of software addresses various disciplines answering the stringent needs in this multifaceted industry.

Explore Our Solutions

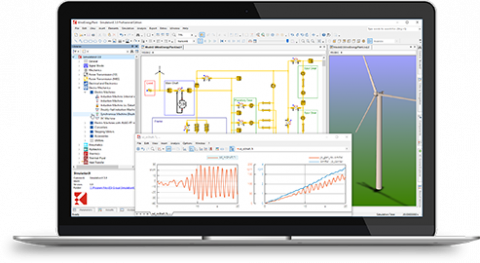

Reaching the optimal health monitoring for wind turbines and reducing operation and maintenance costs while ensuring a high level of performance remains the biggest challenge for Wind Farms. Today, new approaches allow you to alleviate remaining gaps (e.g. data availability, representatively, and physical behavior) and address the specificities of each farm.

In this webinar, we highlight how the coupling of physics-based model with data analytics and machine learning enriches turbine monitoring and opens new fields for Wind Farm owners in their predictive maintenance strategy.

“In the global context of energy transition towards a low carbon society, each stakeholder faces the challenges of innovation, performance and safety compliance with standards to deliver the best time to market.”

Contact Us

Virtual Prototyping for Energy Technologies is Trusted By

All over the world, suppliers, manufacturers and engineering partners use ESI solutions for designing and optimizing energy systems, e.g. ABB Automation, Aker Solutions, Caterpillar Energy Solutions, Eaton Industries, EDF, E.ON Energy Research Center (RWTH Aachen), Framatome, Fuji Electric, GE Jenbacher, Mitsubishi Electric, Mitsubishi Hitachi Power Systems, NEC, Robert Bosch, Siemens, SKF, Vaillant, VEOLIA or Voith Hydro...