Worldwide

Join our upcoming webinar series to learn how to integrate Smart Manufacturing solutions to digitally validate product design’s performance in terms of part quality, production capacity, safety, and assembly operations.

We will address how product development and design engineers can avoid costly rework and production downtime by validating virtually the proposed manufacturing processes and material requirements upfront in the product development process.

3 Webinars to Dive Into the Digitalization of Aerospace Manufacturing

Webinar 1 - Greater Efficiency and Reliability in Manufacturing with Simulation

Guest speakers:

| Scott Pryer, President at Pryer Technology Group & Director of Engineering at PRYER Aerospace Presentation: Metal Forming Challenges for Aerospace |

|

|

Conrad Jones, Sr. Composite Development Engineer at Spirit AeroSystems |

As a building block for digitalization, virtual prototyping solutions are critical components to help all stakeholders achieve manufacturing excellence. Production set up is essential to ensure accuracy and repeatability of produced parts to avoid costly rework, material scrap and wastes.

During this webinar you will learn how comprehensive virtual prototyping and manufacturing process simulation is key to design highly efficient production setup to:

- Increase performance-to-cost ratio while ensuring compliance with aerospace standards

- Leverage more innovative process capabilities in part design

- Secure a cost effective, right first-time process and eliminate scrap & rework

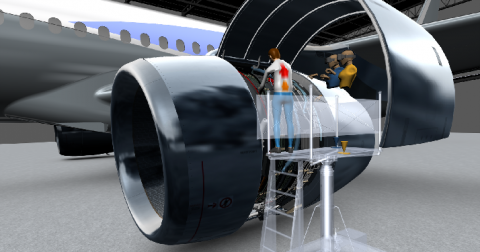

Webinar 2 - Safety & Efficiency Validation of Assembly or Service Processes

AVAILABLE ON-DEMAND LENGTH: 1hConventional manufacturing reviews with the limitations common to digital model interpretation, still result in unforeseen and costly engineering changes for issues that emerge during production of actual aircraft. Waiting until construction of production tooling and fabrication of pre-production parts to conduct final engineering discovery leaves little time to mitigate or eliminate risks.

In this webinar, we will discuss collaborating in "immersive” design reviews, where engineering teams can experience in virtual reality the full scope of the aircraft product and evaluate required human-centric process interactions.

- Experience first-hand potential assembly or maintenance risks and adjust designs or methods to prevent costly production issues

- Make better informed decisions early and provide examples that significantly reduce costly late engineering change orders.

- Enable collaboration among multiple disciplines in widely dispersed teams

- Analyze ergonomics before implementing new designs, tools, and procedures issues

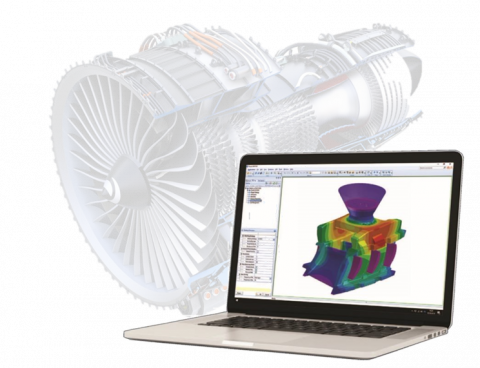

Webinar 3 - Delivering premium quality for high precision parts

AVAILABLE ON-LINE LENGTH: 1hClean aviation, electrification, safety and aircraft sustainability will create more disruptive changes when it comes to the selected material type, shape, production costs, and logistics requirements.

Use of more advanced materials to produce high integrity parts like single crystal HP turbine blade and complex manufacturing processes will be the utmost important challenge part manufacturers must deal with while supplying premium quality, high precision components to the aerospace industry.

Join this webinar to see how comprehensive virtual prototyping and manufacturing solutions help deliver high precision quality parts by:

- gauging the impact of process conditions, to define the process window

- predicting & driving mechanical properties and effects of manufacturing parameters through the design phases

- designing & validating production capabilities, focusing tools & processes, to secure robust implementation of manufacturing process

Applications will Illustrate jet engine components, transmission parts & parts of structures made of special metals involving casting, welding & heat treatment processes, where excellence in process & physics of materials is key to reach the safety and performance targets.