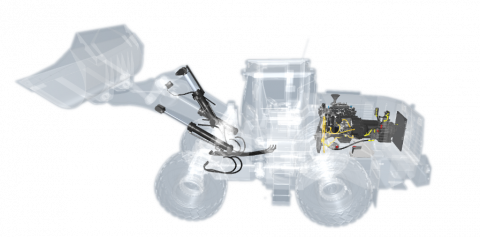

From construction & mining to agricultural and forestry machinery, manufacturers face challenges related to product design and product manufacture, product assembly, and even product operations. They aim to deliver safer, cleaner, and more productive machinery and equipment. Doing this at controlled cost and within set lead times. While committing to maximum productivity and uptime for the toughest usage conditions.

Join us for a webinar series to learn more about achieving early confidence in product performance, realizing efficient enterprise-wide collaboration, and ensuring first-time-right physical prototyping.

Safe, Clean, Productive Machinery

Heavy Off-highway Vehicle Electrification

Operational Safety & Comfort

Deliver Safe, Clean, Productive Machinery & Equipment

Digital Transformation of your Product Performance Lifecycle, through the virtual prototyping of key product and process validations, accelerates product development processes. Establishing a Virtual Proving Ground, Pilot Assembly Hall, and Virtual Service Maintenance Garage to assess upcoming products requires more than a series of disconnected, discrete simulations or deterministic analyses.

Join us in our upcoming webinar, where we will address how the Heavy Industry can design, test, and validate upcoming products for operational comfort & Safety, validate the integration of power, control, and mechanical systems.

Ultimately enabling them to deliver safe, clean, and productive new machinery & equipment designs proven to meet the highest quality requirements and lifetime performance for the toughest usage conditions.

Heavy Off-highway Vehicle Electrification

As Off-highway vehicle OEMs race to bring electric variants of current products to market, program managers and engineers are challenged to design electric powertrains that deliver optimal performance & durability, assure operating safety & comfort, and reduce production & maintenance costs.

Reliable virtual engineering and digital testing methods are essential to model powertrain options and predict system behavior, such as driving performance and energy consumption. Additionally, innovative electric powertrains affect product packaging, cable-hose-wire routing, and systems topology, need to be evaluated for impact on assembly and maintenance processes.

Watch our webinar where we address how to achieve comprehensive and accurate results in a shorter time, driving virtual design and test methods that can fluidly model powertrain design variants and evaluate power consumption in a wide range of operating behaviors and conditions.

Operational Safety & Comfort

Date: April 28th Time: 4pm CET / 11am ET

Delivering successful new products for the construction, mining, and agriculture industries require delivering machinery products that are Safe, Clean, and Productive. However, informing the design and engineering decisions required to assure success without access to the actual product is a challenge remaining in most companies' digital transformation.

Many deterministic methods of testing and evaluating products are discrete simulations of specific conditions meant as a proxy to real-world conditions. While these types of tests are highly illustrative and better than not performing the tests at all, they still occasionally fall short of what is learned when those products are rolled out to actual construction sites, farms or forests, and mines.

Join us on April 28th, during a webinar where we will discuss how leading enterprises are applying virtual prototyping to gain necessary holistic product analysis insights. Ultimately assuring the delivery of Safe, Clean, and Productive machinery for their customer's mines, farms, forests, and construction sites.