PAM-COMPOSITES

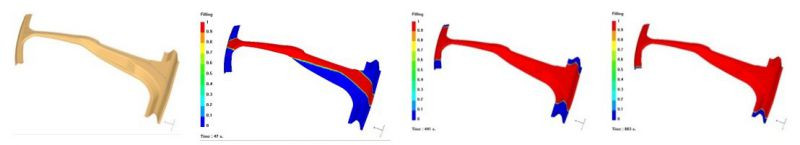

PAM-RTM, the resin molding software module within PAM-COMPOSITES, is used to simulate the resin injection or the resin infusion of a preform.

PAM-RTM can model a wide range of processes including:

- Resin Transfer Molding (RTM)

- Vacuum Assisted Resin Infusion (VARI)

- Compression RTM (CRTM)

- High-Pressure RTM (HP-RTM)

- and many more

This module predicts how the resin flows in a preform that might include inserts (metals, wood, foam).

Typically, simulation results reveal:

- filling time

- risk of dry spots appearance or fiber washing

- flow front velocity

- pressure applied to the mold

With PAM-RTM, eliminate RTM manufacturing defects and improve product quality, upfront in the product development process, before any tools are cut, thanks to the optimization of the following process parameters:

- injection/infusion strategy (choice of LCM – Liquid Composite Molding - process)

- injection pressure or flow rate

- temperature cycle (tool and resin)

- location of injection gates, vents, and vacuum ports

- type and positioning of the flow media

Simulation can also be used later in the process to correct manufacturing issues after they are identified.