Harnessing the Power of AR/VR To Tackle Assembly and Maintenance Challenges in Smart Factories

Paris, France – March 19, 2019 – ESI Group, pioneer in Virtual Prototyping and creator of IC.IDO, the leading Virtual Reality (VR) solution for industrial applications, will exhibit at the 21st edition of Laval Virtual, March 20-24 in Laval, France. Along with Diota, a leader in Digital-Field software solutions for Industry, ESI will present for the first time a live demonstration of their common value proposition, combining VR and AR within an operator-centered digital continuity solution. Together, they will address challenges related to factory assembly and in-service maintenance through an end-to-end solution that efficiently leverages digital data to achieve improved productivity, quality and traceability while decreasing operational risk.

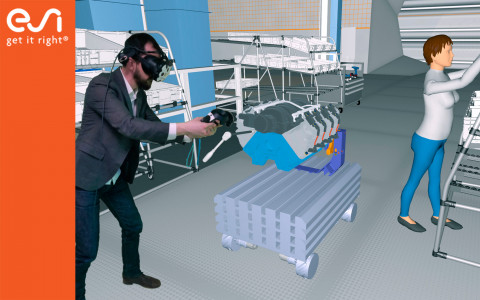

Manufacturers realistically experience and validate assembly and maintenance procedures in real-scale and real-time thanks to ESI’s Virtual Reality solution IC.IDO. Image courtesy of ESI Group.

For manufacturing enterprises across all industries, digital transformation brings sizable opportunities to reduce cost and delays for product development and manufacturing. VR has made its way into product and process development, where it helps engineers identify design risks as early as possible in the product or process lifecycles. Used at Boeing, Bombardier, Fiat Chrysler Automobiles, Ford and Safran amongst other leading OEMs, ESI IC.IDO is the leading VR solution for industrial applications. At Laval Virtual, ESI will showcase several use cases with specific focus on human-centric assembly process validation ─ a critical aspect of Industry 4.0 where ergonomics and workflows need to be completely rethought for operators to deliver optimum efficiency whilst interacting with layers of new technologies.

Augmented Reality also delivers important benefits for manufacturing assembly, once on the shop floor. Diota’s solutions help factory operators to better understand and carry out complex operations through step by step digital work instructions and contextualized contents visualized in their workspace.

As highlighted by ESI and Diota’s partnership, the combined use of VR and AR provides a unique opportunity for companies to achieve digital continuity between the validation and distribution of manufacturing and maintenance procedures. At Laval Virtual, ESI and Diota will demonstrate how a joint usage of their solutions addresses issues arising in the definition and execution of procedural information by making sure factory operators access optimized and up-to-date product design information and work instructions whenever they need it, on-the-job or during training.

Experience AR/VR synergies at Laval Virtual!

Visitors to ESI’s booth (E5) will immersively experience assembly steps to build an automotive engine in VR. Across the alley, on Diota’s booth (E25), they will visualize and interact with the corresponding digital instructions on the real engine, just like an operator would.

A concrete way to have an overview of this seamless workflow and its benefits in terms of performance for highly complex processes involving human workers.

ESI Group - Contacts

Media Relations

celine.gallerne [at] esi-group.com (Celine Gallerne)

+33 1 41 73 58 46