ESI provides advanced simulation of the Centrifugal Casting process for large Titanium structural components

Paris, France – March 7, 2014 – ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, announces the release of an important study focusing on process modeling of centrifugal casting of large titanium structural components. Study results will contribute to the rapid development of cost-efficient manufacturing techniques for titanium parts for uses in the aeronautic sector. Such advances will reinforce the competitiveness of both Europe and China in the aeronautic sector, while strengthening strategic international cooperation between the two regions.

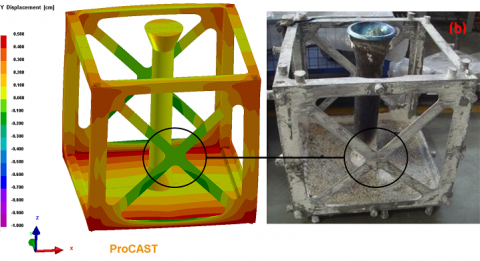

The deformation (right) observed in the cross beams of the cubic shaped frame are in good agreement with the predicted results (left).

The study was completed as part of the COLTS project, a research project funded by the European Commission in its Seventh Framework Programme, or FP7. Ole Köser, Manager of ESI’s Center of Excellence for Casting and Metallurgy and leader of the team participating in the COLTS project, comments: “European projects significantly contribute to ESI’s research activity, enabling us to better support our clients in driving industrial innovation.”

Titanium alloy was the main focus of the COLTS project because of the potential for weight reduction of components in airframes, spacecraft and aero engines, and the consequent fuel economy and reduced greenhouse gas.

The most cost-efficient way to produce such titanium components is to use a clean-melting technology named skull melting, which limits the superheat of the molten alloy to about 40°C above its melting point. The relatively low temperature of the melt requires the use of centrifugal casting or very sophisticated gravity casting processes.

Project partners elected to use ESI’s casting simulation software to support the application of advanced centrifugal casting processes, specifically tailored for thin walled titanium structures.

To support this project effectively casting simulation had to enable the early prediction of potential problems such as filling-related defects (inclusions, misruns, blowholes…), porosity formed during solidification, and deformation during subsequent cooling. This had to be done in such a way that the effect of process parameters (including filling time, filling temperature, mold pre-heating temperature, and mold rotation speed) could be readily assessed.

ESI extended the capabilities of ESI’s casting simulation software, ProCAST during the course of the project; improving its fluid-flow solver to handle complex turbulent flow pattern and including the effect of the direction of the centrifugal force on porosity formation.

“The extended functionalities of ProCAST, gained through the COLTS project, will be invaluable at industrial level to set up cost-efficient centrifugal casting processes for titanium parts. Manufacturers using the software will gain a considerable amount of time and money, contributing to the production of better quality parts for aeronautical applications, both in Europe and in China,” says Dr Rui Yang, Director from the Institute of Metal Research in China, who participated in the COLTS project.

ESI will present the complete study at the 71st World Foundry Congress, taking place in Bilbao, Spain, May 19 to 21.

For more information about ESI’s casting solutions, please visit www.esi-group.com/casting

For more news or information about ESI, please visit www.esi-group.com

Connect with ESI on LinkedIn, Twitter, Facebook, and YouTube

ESI Group – Media Relations

Céline Gallerne

Celine.Gallerne [at] esi-group.com'; // --> //-->

T: +33 (0)1 41 73 58 46