Worldwide

On-Demand

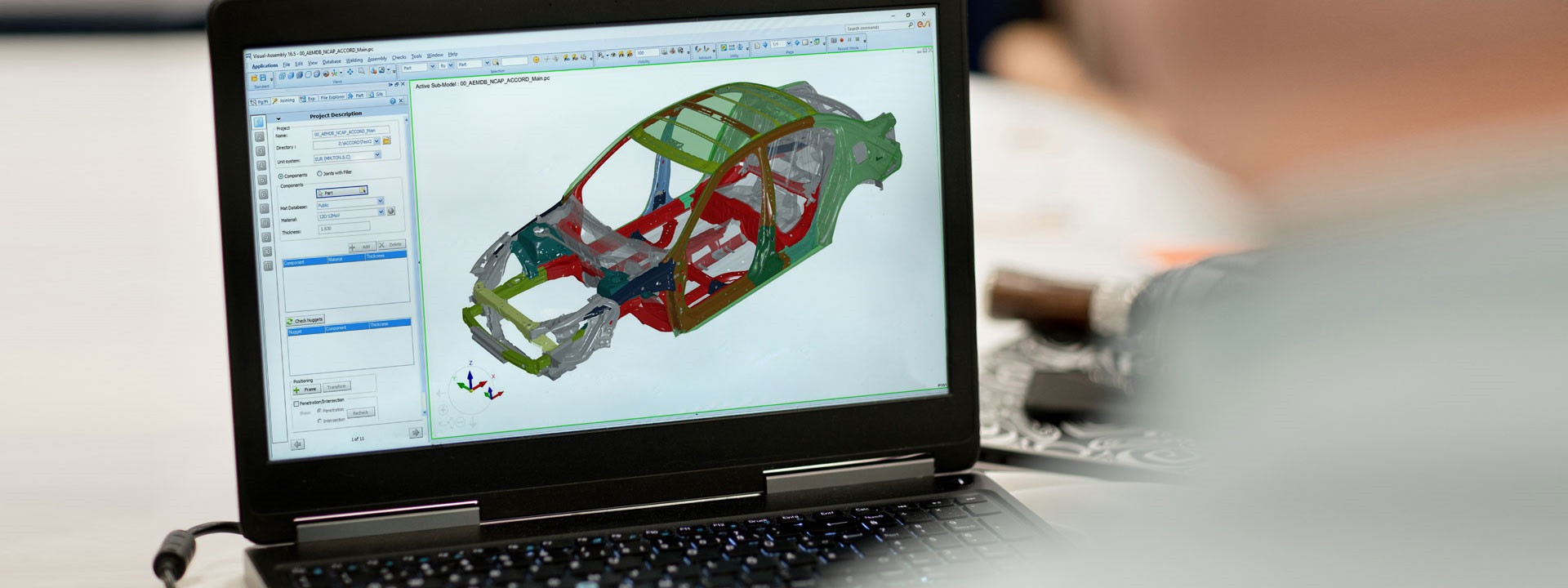

Lightweight has become the new must-have in body and chassis design. Multi-material assemblies are key to producing vehicle bodies with the best cost/lightweight ratio. However, it is a complex task to find the right material mix, apply the right material at the right place, optimize geometries and thicknesses, define the various manufacturing processes and select the optimal joining technologies.

All this is no longer efficiently achievable with single-point numerical simulations. Instead, automakers need to tightly couple the engineering and the manufacturing world in order to make the right choice as early as possible.

4 Webinars to Dive Into the Engineering and Manufacturing of Body & Chassis assemblies

Introductory Webinar - Engineer & Manufacture Multi-Material Body and Chassis Assemblies with Confidence

AVAILABLE ON-DEMAND LENGTH: 1h

From frontloaded manufacturing feasibility assessment for design, over predictive performance analysis considering the manufacturing impact, through to the complete simulation and validation of the manufacturing processes early in the development – this introductory Webinar will explain our end-to-end vision with target to get the assembly right the first time. Improve dimensional accuracy of body and chassis assemblies, optimize your manufacturing processes and make quality compliance control – all fully virtual in a fluid journey through production.

In addition, with regards to the electrification challenge, multi-material assemblies are key to producing vehicle bodies with the best cost-lightweight ratio. However, currently higher investments on the powertrain side translate into more conservative investments on the body and chassis side. This increases the pressure to achieve better cost efficiency in engineering and manufacturing for those vehicles.

Attend our webinar series to achieve confidence in the optimum design earlier and reduce vehicle lead times drastically by predicting physics and processes accurately. Each Webinar of the series will cover the problematics related to specific assemblies of the vehicle: Doors & Closures, then Body in White, and finally Chassis.

Webinar 2 - Assembly Distortion Control and Perceived Quality | Doors & Closures

AVAILABLE ON-DEMAND LENGTH: 1hManufacturing cars with lightweight materials is a challenge for meeting tolerance requirements and final perceived quality, with the consequence to increase the risks for over-spending in the try-out phase. To meet customer’s high demands while minimizing cost, OEMs must ensure class leading craftsmanship and operational performance of manufacturing processes.

From the optimization of manufacturing processes (stamping, casting or composite molding), to the joining processes validation, and eventually to the surface quality check-up in the virtual light room, capture all relevant data to build an effective process chain, test heat treatment and thermal expansion phenomena and adjust your single parts design quickly in order to prevent distortions on the final assembly.

In this webinar we will discuss how virtual prototyping can help engineers to manage the key manufacturing and assembly processes for Doors and Closures – all along the development cycle.

Webinar 3 - Assembly Distortion Control and Crash Prediction | BiW Assemblies

AVAILABLE ON-DEMAND LENGTH: 1hEnsuring the dimensional accuracy of a complete Body in White (BiW) during the pre-production phase is a balancing act between dealing with the realities of distributed supply chain and aggressive timelines to achieve a repeatable, robust, and reliable final assembly. Whether the final distortions are the result of decisions made in the weld fixture design, inaccuracies in constituent sheet metal parts and sub-assemblies, unanticipated thermal distortion effects, or from any other sources, it is a big challenge to manage the distortions on the final assembly.

Virtual trials can play a significant role in the optimization of the welding and assembly processes at pre-production phase, but also in earlier phases by simulating the complete manufacturing chain to anticipate potential issues. Validation of the crash performances that takes account of the welding effects more accurately plays also an important role in the prediction of joints strength to avoid unforeseen cracks during testing, and late changes in the assembly planning.

This webinar will cover how to manage distortion of assemblies at various stages of the process, and how to use results of spot welded assemblies for crash prediction.

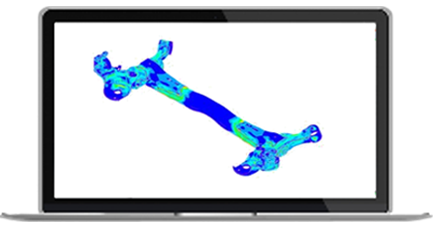

Webinar 4 - Assembly Distortion Control and Fatigue Prediction | Chassis & Suspension

ON-DEMAND ACCESS LENGTH: 1hWhile lightweight designs & the use of high strength material are a key enabler for lighter and more performant chassis and suspension components, this also brings more spring back and less formability of the parts, and more challenges for excellence in fabrication of parts & assemblies, and consequently the overall cost and time spent. Chassis of larger seam welded transportation vehicles incorporate in general a significant effort to control and eventually repair distortion, as well as any seam welded aluminum design.

With Virtual Prototyping, you are able to manage the manufacturing processes of the parts and the heat effects of welded assemblies. You can thus ensure geometrical quality of welded designs and find the optimum fit and tolerance margins to get your welded assemblies right the first time

This webinar will highlight the prediction and control of distortions in welded chassis & suspension designs, from support in the early design & process planning phase to final process validation. Aspects of chaining with part manufacturing processes as well as using the results of the entire process chain for fatigue evaluations will be discussed.