IZB Wolfsburg 2022

Germany, Wolfsburg

Hall 5 / Stand 5220

This October, ESI will take part in the IZB Wolfsburg, a key meeting for the automotive supplier community.

This year, the ESI team will demonstrate the benefits of Human Centric Assembly and Product Validation using IC.IDO, its an interactive and collaborative Virtual Reality Solution. In this immersive Virtual Reality, you will be able to walk around your product in a true-to-life environment at a 1:1 scale, look at it, reach for needed tools, and interact with your new product concepts as you, or your customers, would in real life.

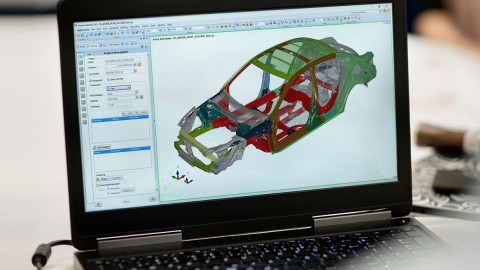

We will also present how end-to-end virtual prototyping is the best way to reduce your overall product development cycle, cost, and time to start of production (SOP) by getting your sustainable vehicle engineering, manufacturing, and assembly processes right.

Reach out to us to schedule a dedicated meeting and demo.

Human-Centric Validation in Action

- Discover if the real product or finished assembly has inconsistencies, flaws, or errors that are not evident in concepts or designs until you experienced the build

- Mitigate risk of unobserved production and assembly issues

- Ensure new products are appropriately modeled during the design and commissioning of the production tools, processes, and facilities

- Validate all the leading lightweight material candidates for vehicle structures' safety-critical components

- Optimum joining processes to achieve assemblies at the best performance/cost/quality ratio

Multi-Material Joining & Assembly in Action

- Predicting manufacturing, assembly, and performance through accurate representation of physics and applied processes

- Validation of all lightweight materials (standard steel, high-strength steels, aluminum, composites) regardless of what process they have been manufactured through (standard stamping, hot-forming, casting)

- Unlimited try-outs to find the most efficient manufacturing processes and achieve optimal cost/quality ratio

- Reduction of expensive physical prototypes and time-consuming try-out iterations

Development And Virtual Testing of Electrified Vehicle Prototypes

Discover what a powerful and reliable solution for EV cabin and battery development looks like and what you need to create a truly smart cabin experience. Enabling you to design your EV at the system level at the very early stage

From thermal management and battery design to energy management and powertrain - dimension all components of the electrical machine, battery, and transmission elements, including field-oriented control and rectifiers. With advanced multi-domain system modeling of the EV, main components engineers understand and master complex mechatronic correlations.

- Reduce the number of cooling circuits, reduce mass, gain space.

- Find the optimum capacity and performance of your battery in terms of costs, installation space, range, and service life: The highly dynamic power flow of the electric drive and battery’s recuperation places high demands on the energy supply. Cooling the battery at high temperatures (or heating at low ones) also has a major influence on its performance and service life.