thyssenkrupp Steering Relies on VPS to Ensure Fast Development of High-Quality Steering Components for Ultimate OEM Satisfaction

In the highly competitive automotive industry, Original Equipment Manufacturers (OEMs) and their suppliers face immense pressure to develop components that meet stringent safety and performance standards while adhering to tight deadlines. Among these crucial components is the steering column, which plays a pivotal role in vehicle safety and functionality.

To streamline the development and validation process, both OEMs and their component suppliers rely on advanced simulation software. This case study highlights how the steering system supplier thyssenkrupp Steering integrated ESI’s virtual performance solution software (VPS) into their workflow and how the tool helps the supplier meet the demanding modeling and testing requirements of their OEM clients.

Balancing Accuracy, Safety, and OEM Demands

One of the leading suppliers is thyssenkrupp Steering, an internationally active business unit of the Automotive Technology segment of thyssenkrupp AG. In it’s center of business in Liechtenstein, the company produces and develops steering systems for more than 30 million vehicles annually.

In its role as an automotive supplier, thyssenkrupp Steering must develop high-quality components that comply with safety regulations while meeting the specific modeling requirements set by its OEM clients. This is where compliance, accuracy, and speed are crucial. When an OEM prefers a specific simulation tool like ESI’s VPS software for their vehicle crash performance simulations, they typically require their suppliers to use the same tool. This ensures seamless integration and compatibility between the supplier's models and the OEM's simulations, ultimately guaranteeing that the final product meets stringent safety standards.

This workflow creates unique challenges for suppliers like thyssenkrupp Steering:

- OEM-Specific Modeling Requirements | OEMs demand that suppliers provide highly accurate, VPS-compatible models as part of the development process.

- Precision in Simulation Models | Suppliers must develop highly precise models that accurately reflect real-world performance, ensuring the validity of the OEM's crash simulation results.

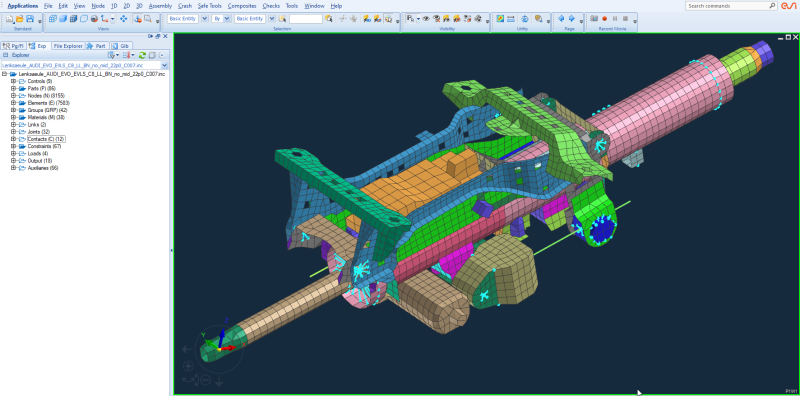

- Model Complexity | Creating and analyzing complex models that account for various factors, such as material properties, geometry, mechanical forces, thermal influences, and the effects of shocks or vibrations, while conducting multiple iterations to optimize the design for accurate simulation results.

- Safety Compliance | Ensuring that steering columns meet strict safety regulations and perform well under various crash scenarios.

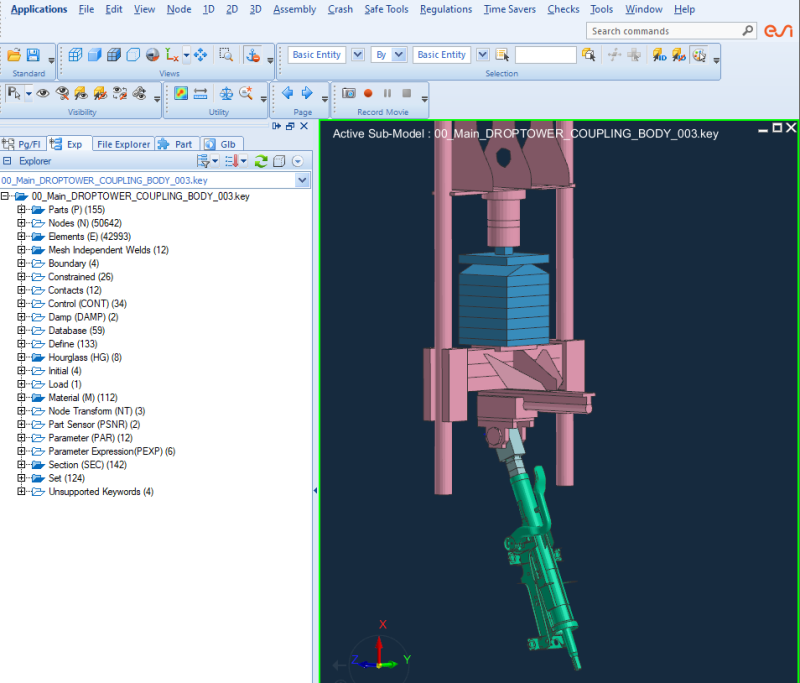

thyssenkrupp Steering's CAE team has been leveraging the multiple crash solver and powerful modeling and simulation capabilities of ESI’s Virtual Performance Solution (VPS) to streamline the work of their analysts on detailed components. VPS provides a clear representation of models, and its intuitive interface and robust features allow them to optimize steering column models in an organized manner. This enables the team to quickly generate precise models, which is essential for reliable simulation results.

Director CAEthyssenkrupp Steering

Ensuring a Streamlined, Compatible Model Development Process

To address these challenges, the steering column supplier adopted VPS to streamline their model-building process and ensure compatibility with the OEM’s simulation requirements. Using VPS’s powerful capabilities for multiple crash solvers, thyssenkrupp’s development team was able to efficiently create and optimize detailed steering column models. The tool's intuitive interface allowed the team to organize complex models with precision, ensuring accurate simulation results. This allowed the supplier to quickly provide the OEM with models that met all performance and safety standards.

The impact of using VPS from ESI is clear in thyssenkrupp Steering's recent projects. The team has successfully developed several steering column models that meet stringent safety standards, and the ability to quickly iterate and refine our designs has given them a competitive edge. VPS has significantly streamlined their workflow in steering column development. Its features are crucial for an efficient and smooth process. In one project with particularly demanding customers, they were able to create a detailed and precise model thanks to the unique capabilities of VPS. This experience really demonstrated how valuable these tools are in engineers' daily work.

Director CAEthyssenkrupp Steering

Efficiently Tackling the Complexities of Steering Column Development

For thyssenkrupp Steering, VPS offers a powerful solution to meet safety and performance standards, ensuring compatibility with OEM crash & safety simulations while driving productivity and product quality improvements.

The integration of our VPS into the thyssenkrupp’s development workflow proved to be key: The supplier was able to meet the detailed modeling requirements of their OEM client, deliver accurate simulation models, and enhance their overall development efficiency. Benefits include:

- Faster Model Creation | With VPS, the supplier was able to accelerate the development of steering column models, allowing them to meet OEM deadlines with ease.

- Accurate Simulations | The detailed and precise models created using VPS resulted in reliable simulation outcomes, ensuring that the steering columns met stringent safety requirements.

- Improved Efficiency | VPS streamlined the model-building process, reducing the time and effort required to achieve the necessary level of detail in component models. This resulted in higher productivity for the supplier's engineering team.

In summary, the use of VPS has complemented thyssenkrupp Steering's working environment for steering column development. Through efficient model building and validated simulations, the team has achieved significant improvements in both productivity and product quality. We look forward to continuing to innovate and deliver exceptional results with the support of this powerful working environment

Director CAEthyssenkrupp Steering