Shaping the Future of Flight: How simulation accelerates innovation in Sheet Metal Forming in Aerospace Manufacturing

Enhancing formability and material utilization through simulation

The aerospace industry stands at the cutting edge of precision engineering, constantly seeking lighter, stronger, and more efficient components. One key process behind this innovation is sheet metal forming—a group of advanced manufacturing techniques that enable the creation of complex, high-performance and high-precision parts.

As aircraft become more sophisticated, manufacturers are also turning to simulation software to optimize their sheet metal forming processes, reduce costs, and accelerate development cycles.

In this post, we’ll explore how sheet metal forming shapes key aerospace components, take a more detailed look at some of the advanced forming techniques which are widely used in the industry, and learn more about how simulation is helping to change the way parts are designed and manufactured.

Why Sheet Metal Forming is Essential in Aerospace

Aerospace components must meet strict requirements for strength, weight, precision, and durability. Sheet metal forming offers the ideal combination for producing parts with these attributes, enabling the production of both structural and non-structural parts. Here’s a breakdown of some key components made using these methods—and why sheet metal forming is the process of choice:

1. Fuselage Skins

Forming processes create large, smooth, aerodynamically efficient surfaces with minimal seams. High-strength aluminum alloys are commonly used, providing excellent structural integrity and pressure resistance.

2. Wing Skins and Panels

These need to be both strong and lightweight. Stretch forming techniques preserve material properties while shaping complex contours crucial for aerodynamic lift.

3. Engine Nacelles and Cowls

Precision and heat resistance are critical here. Sheet metal forming allows the creation of tight-tolerance, curved parts using materials like Inconel or titanium.

4. Fairings

These drag-reducing components are shaped efficiently using forming processes, producing lightweight, thin-walled parts with complex geometries.

5. Brackets and Support Structures

Bending and stamping allow fast, cost-effective production of small yet essential load-bearing components inside the aircraft.

Industry Certification Requirements

Manufacturing facilities must maintain AS9100D certification as the fundamental quality management standard for aerospace operations. This comprehensive framework encompasses material traceability, process validation, and risk management protocols. Simulation software helps aerospace manufacturers maintain this certification by enabling the virtual validation of metal forming processes-reducing physical prototyping and associated risks. It ensures consistent product quality by predicting defects, supports traceability through documented simulations, and optimizes material use and tooling design. These capabilities align with AS9100D’s focus on risk management, process control, and continuous improvement.

Beyond AS9100D, manufacturers pursuing specialized processes need NADCAP accreditation in areas like heat treatment and non-destructive testing. For example, a facility performing chemical processing on titanium components must demonstrate compliance with strict environmental controls and process parameters.

Leading manufacturers now integrate ISO 14001 environmental management systems with their quality certifications, ensuring sustainable practices throughout the production chain. Regular third-party audits verify conformance to these standards, with documentation requirements extending to raw material sources and supplier qualifications.

Advanced Sheet Metal Forming Techniques in Aerospace

With lower production volumes and highly complex component geometries, the aerospace industry requires more flexible and precise forming methods in comparison to most other industries, such as automotive. These techniques are better suited for producing intricate shapes with tight tolerances-essential for maintaining structural integrity and aerodynamic performance. Additionally, the wide variation in component sizes—from small brackets to large fuselage and wing sections—necessitates processes that can accommodate both fine detail and large-scale precision, often with thin, lightweight materials. This complexity drives the need for diverse and specialized forming approaches.

Here are some key techniques used today:

Superplastic Forming (SPF) is a highly specialized technique that leverages the unique properties of certain titanium and aluminum alloys to undergo extensive plastic deformation at elevated temperatures. During SPF, gas pressure is applied to sheet metal heated to superplastic conditions, allowing it to stretch into intricate shapes without cracking or thinning unevenly. This process is especially advantageous in the aerospace industry, where it’s used to form complex parts such as fuselage panels and engine components. One of its major benefits is the ability to produce components with highly intricate geometries from a single sheet, reducing the need for multiple joined parts, minimizing material waste, and improving overall structural integrity.

Hot Forming is used to enhance the formability and performance of high-strength materials like titanium and aluminium. In hot forming, metal is heated below its melting point and then pressed into shape, improving ductility and reducing distortion. This results in better dimensional accuracy and lower residual stresses in the final part.

Hydroforming is a versatile metal forming technique where high-pressure hydraulic fluid is used to press a metal sheet or tube into a die, creating precise and smooth shapes. This method is widely used in aerospace manufacturing to produce components such as fuselage sections, wing ribs, and various structural supports , as it allows for complex shapes to be formed from a single piece of metal, leading to weight savings and improved aerodynamic performance.

Incremental Sheet Forming (ISF) is a highly flexible and adaptive technique in which a small tool, often mounted on a CNC or robotic arm, incrementally deforms a sheet of metal into the desired shape. Unlike traditional stamping, ISF does not require dedicated dies, which significantly reduces setup costs and time. This makes it especially suitable for prototyping, experimental designs, and low-volume production runs in aerospace development. The process allows for a high degree of customization, enabling engineers to quickly iterate on complex component shapes without incurring the cost or delay of fabricating new tooling.

Roll Forming is a continuous metal forming process in which a flat sheet of metal is passed through a series of shaped rollers to achieve a precise cross-sectional profile. This method is particularly well-suited for producing long aerospace structural components, such as stiffeners, beams, and fuselage reinforcements. Roll forming offers excellent dimensional control, repeatability, and material utilization. It also allows for high-speed production with minimal waste, making it a cost-effective solution for fabricating lightweight and durable structural elements in modern aircraft.

Rubber Pad Forming is a flexible sheet metal forming process widely used for shaping lightweight, high-precision components. Instead of a traditional die, it uses a rubber pad to press metal sheets against a rigid punch, allowing for the creation of complex shapes with excellent surface finishes. This method is especially valuable for low-volume production, and the forming of delicate or thin materials.

While the variety of different forming techniques enables manufacturers to choose the best process for making a specific part, it still doesn’t guarantee 100% accuracy for the finished part.

The Role of Simulation Software in Sheet Metal Forming

Aerospace manufacturers face challenges in sheet metal forming due to the use of hard-to-form materials, the need for precise tolerances, and complex part geometries. Issues like springback, tool wear, material waste, and multi-stage process complexity increase costs and risks. Additionally, strict regulatory standards demand validated, traceable processes, making prototyping and production both time-consuming and expensive.

So manufacturers are turning to predictive simulation platforms to validate complex forming processes, refining and streamlining production workflows well before physical production begins. These tools allow for in-depth analysis of material behavior under various conditions, significantly reducing the need for multiple prototype iterations.

By simulating how metals respond to deformation, pressure, heat, and stress, engineers can avoid common defects such as wrinkling, extreme thinning, or cracking, significantly reducing the need for physical trial-and-error. Virtual testing also supports better resource management by identifying optimal blank sizes and tool paths or kinematics, which lowers material waste and overall production costs.

In addition, simulation software enhances process efficiency by fine-tuning parameters like lubrication strategies, tool speeds, and thermal cycles. This leads to more consistent quality and effectively mitigates issues such as springback. When it comes to tooling, these advanced capabilities help identify areas prone to wear or stress and heat concentration, improving tool longevity and supporting the design of dies that produce high-precision parts.

Engineers also benefit from the ability to evaluate multiple design iterations digitally, selecting the best-performing option before any metal is cut. This accelerates product development timelines and reduces costly design changes late in the process. Finally, simulation ensures that aerospace components meet strict industry regulations, including FAA and EASA standards, by validating critical factors like mechanical performance, fatigue resistance, and manufacturability upfront.

Solving Aerospace Sheet Metal Forming Challenges with PAM-STAMP

With over 25 years of proven track record in the aerospace industry, PAM-STAMP is a trusted and versatile solution for addressing a wide range of sheet metal forming challenges. Designed to support advanced and flexible forming processes, the platform provides a unified environment that spans the entire development cycle—from initial part and tool design through to production.

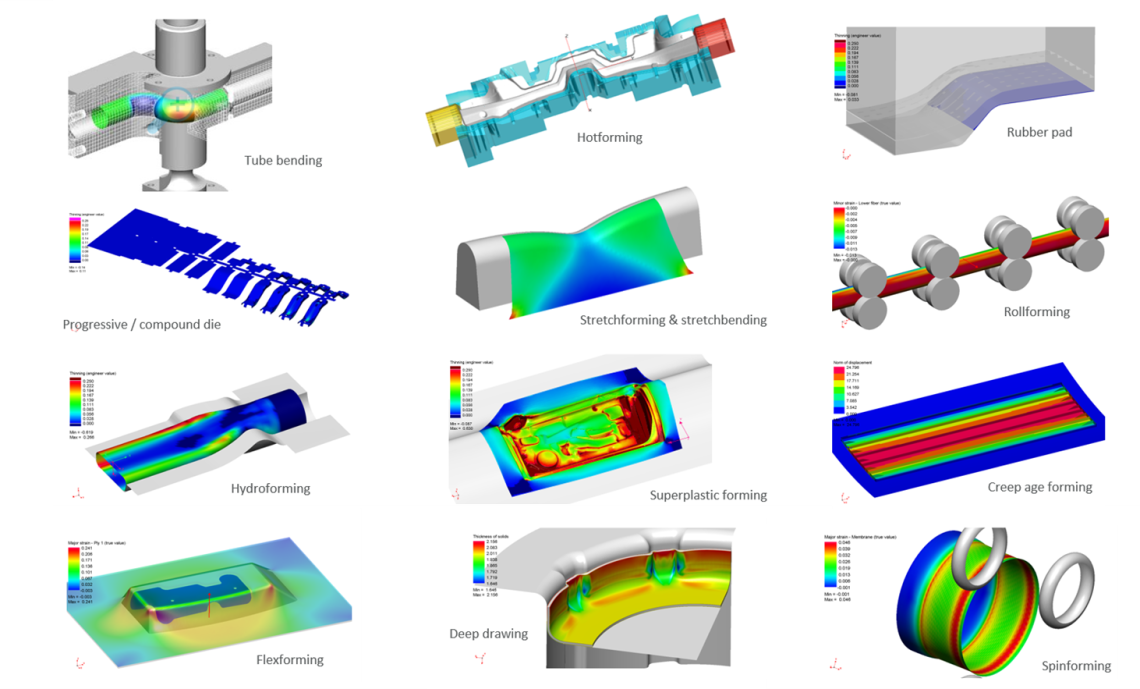

PAM-STAMP's intuitive and process-driven interface includes a library of easy-to-use templates and workflows tailored to specific processes such as tube bending, hydroforming, and hot forming. These templates enable standard manufacturing engineers to achieve high-quality, predictive simulation results. At the same time, the software’s open architecture makes it an excellent tool for experts and researchers, offering deep control over both process parameters and FEM (finite element method) numerics—ideal for innovation and advanced research into new materials and process techniques for the next generation of aircraft.

The platform excels in analyzing material behavior under various thermal conditions, making it especially valuable for optimizing the forming of critical aerospace components. Whether working with conventional aluminium or other cutting-edge lightweight alloys, simple shapes or highly complex structures, PAM-STAMP supports the successful production of sheet metal parts, and when combined with support for cold, warm, and hot forming, ensures precision and efficiency across every stage of the manufacturing process.

Its powerful solver supports scaling on multiple cores, making it possible to run calculations on standard computers, as well as on large clusters for very large and complex components, while still giving results in industrially acceptable timeframes.

For more information visit the PAM-STAMP webpage or download the eBook on Virtual Manufacturing in Aerospace.

Get in touch

Katharine Edmonds is a Content Marketing Specialist at ESI Group, and has spent the past 9 years working in marketing and communications for SaaS providers in the engineering and manufacturing industries. Katharine leans on her knowledge and experience of CAD, PLM and eXtended Reality (XR) technologies to create engaging and informative content that champions the benefits of virtual prototyping, and bridges the gap between complex technical subjects and a broader audience.