GIFA 2023 - 15th International Foundry Trade Fair with Technical Forum | ESI Group

aynur.haghighi [at] esi-group.com (aynur[dot]haghighi[at]esi-group[dot]com)

Cast All Your Parts Right the First Time

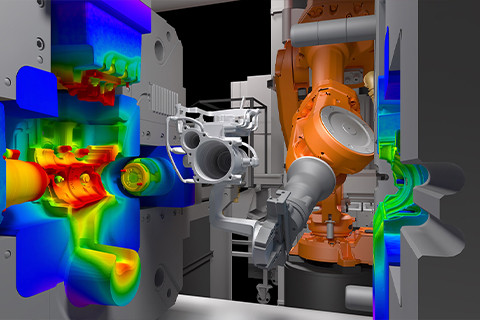

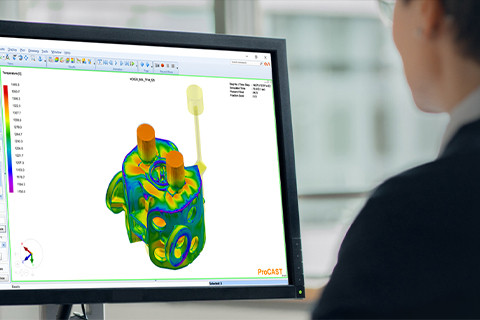

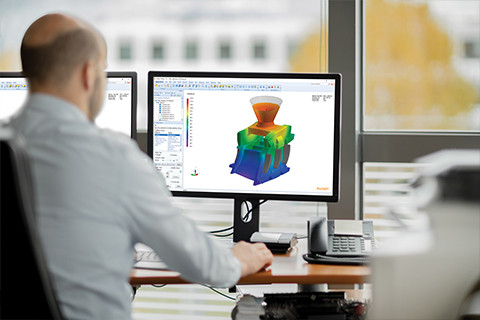

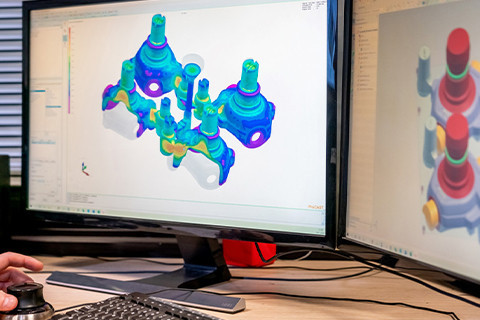

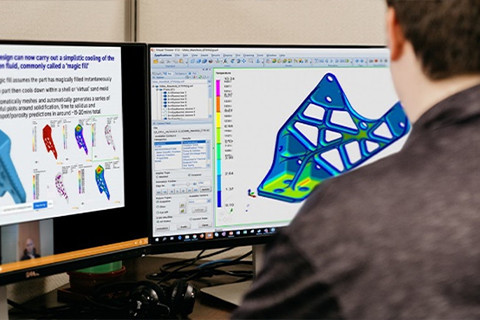

with ESI's ProCAST Casting Simulation Software

Your first parts from the trial are finally available, only for you to realize they contain defects not meeting the quality requirements. How long is your deadline to go back to the design stage, try to identify the problem, and correct it? Do you then have all the confidence that the part is finally free from defects? Casting simulation allows for virtual testing early in the development stage. This is key to meeting deadlines and stopping the waste of money on scrap parts or late designs.

For decades, engineers have relied upon casting simulation with ESI’s ProCAST as their go-to software for efficiently predicting casting basics and effectively solving deformations and residual stresses.

See the latest best practices from the global ProCAST community at GIFA 2023. At ESI’s booth H44 in hall 11, our casting engineers will help you make sense of the role and value of casting simulation for your work.

Experience Innovation at GIFA!

Discover how our expertise and technology can help you achieve your business goals with smart casting simulation solutions. Book a meeting with our experts to find out how.

What to expect:

- Tailored Demos: Let us know about your challenges and needs, and we'll create a demo that fits perfectly.

- Customer Success Stories: Discover how our expertise and technology have helped numerous businesses achieve innovative results.

- Insights: expand your knowledge about casting simulation and stay up-to-date on the latest trends

- Teaser video: Check out a sneak peek of our most recent work with SIMPLAC and see how we helped them achieve success.

- Networking Opportunities: Connect with our team and our casting expert partner, Ecotre, to grow your business.

- Book a Meeting Now: Don't miss the chance to explore how our solutions can help you achieve your goals.