How can you test and validate the safety, comfort, reliability, and durability of a mobile machine, truck or bus when it is being used as intended? And when it’s not? Where to draw the line between use, misuse, and abuse? Remote work, market changes towards electrification, automation, and other technological trends are only complicating already challenging product development activities with reduced accessibility to physical testing.

Don’t leave product performance aside until a physical prototype becomes available. Go virtual to reduce cost, time to market and unseen risks as early as possible in the design process!

"We assume that we can save 1.5 to 2 years of development time because the virtual proving ground will help accelerate engineering iterations and frontload the redesign process into the development phases."

Paulo MarquesCTO, CaetanoBus

What is a Virtual Proving Ground used for?

Prioritizing the comfort and safety of operators of mobile and heavy machinery is paramount for optimizing overall productivity. However, designing products that seamlessly blend human and machine interaction poses significant challenges. Leveraging virtual prototyping and digitalization in the early design phases allows for informed decision-making and proactive design adjustments. By simulating various terrains and climates, including extreme and hazardous conditions, the "Virtual" proving ground expands testing capabilities beyond real-world limitations such as budget and safety constraints. This innovative approach facilitates rapid improvements in system topology, component selection, variant studies, and system integration from the onset of product development.

In a nutshell: The Virtual Proving Ground is the virtual counterpart of the windy, dusty, muddy proving ground on which engineering teams test physical prototypes for their heavy machinery and equipment. It empowers manufacturers of mobile, heavy, agricultural, and construction machinery to create safer, more comfortable, durable, and sustainable products.

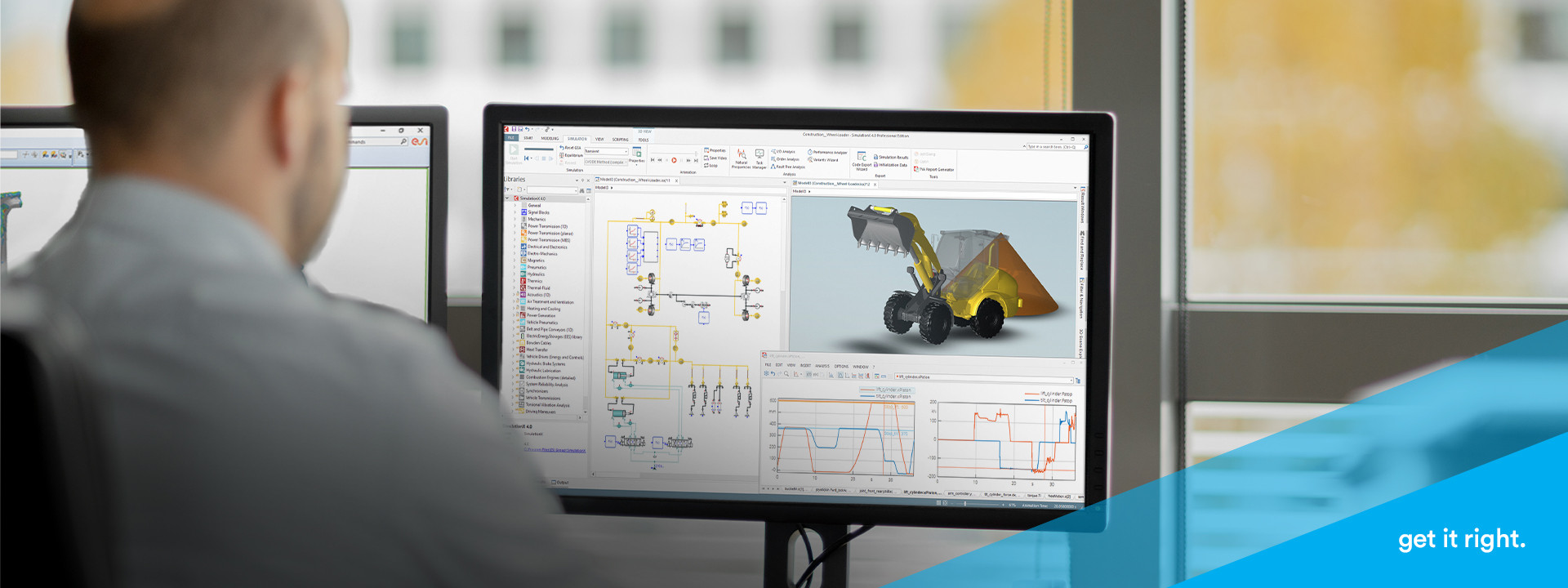

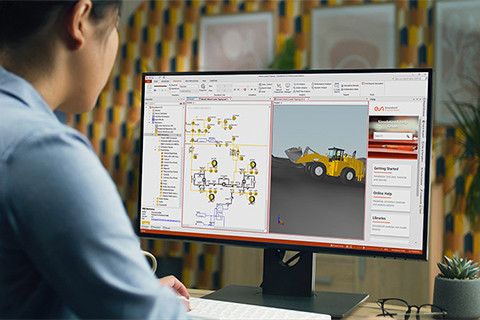

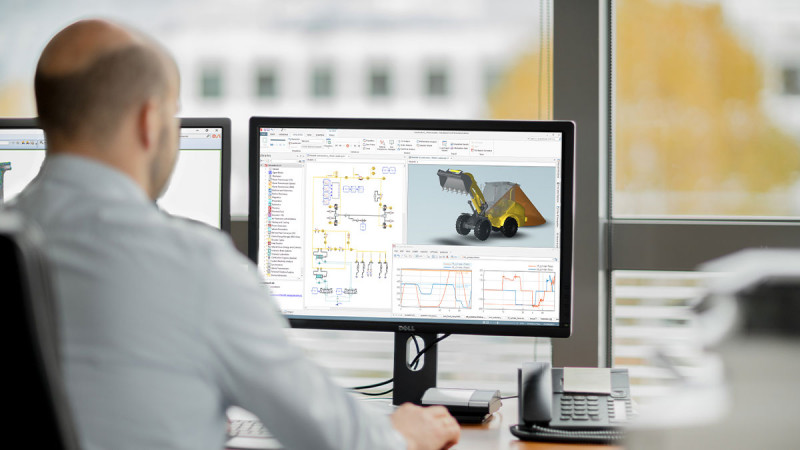

Building your very own Virtual Proving Ground using ESI simulation software, your team will gain the ability to:

- Simulate the physical behavior of an entire machine & subject it to virtual terrains in a single environment

- Design safe, comfortable, clean, and productive machinery & equipment

- Cut down on real tests and prototypes

- Achieve product pre-certification despite constantly evolving regulations

- Face challenges related to product performance across multiple domains, from noise and acoustics to durability

- Make sure operator safety and comfort are a priority

- Include and test control systems

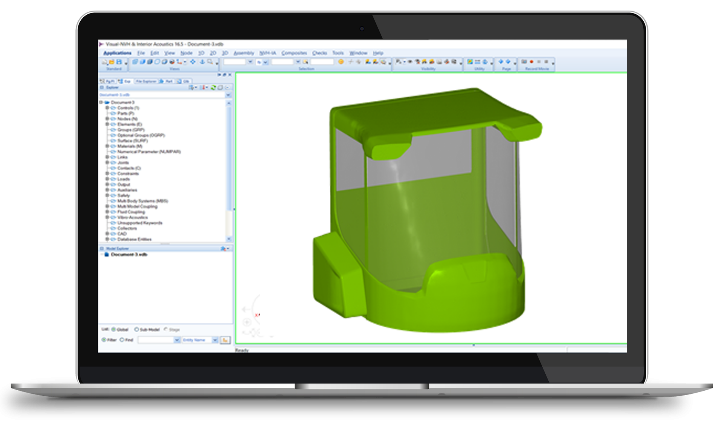

- Evaluate shocks and vibrations experienced by operators at work

- Meet regulations and targets for interior and exterior noise & acoustics

- Ensure best possible visibility, reachability, accessibility

Learn from our experts how to boost ride quality, safety aspects & longevity all virtually

How to leverage digital solutions to deliver safer, cleaner, more sustainable, and more productive machinery and equipment? At the controlled cost and within set lead times? While committing to maximum productivity and uptime for the toughest usage conditions?

Join our expert webinar series on-demand and learn more about how to achieve early confidence in product performance, realize efficient enterprise-wide collaboration, and ensure first-time-right physical prototyping.

Test Operational Safety and Comfort Fully Virtually with ESI Software Solutions

Our numerical simulation software lets you secure the reliability & performance of your machines as used, as soon as possible in your product development process. They allow engineering teams to test product performance as-operated, as-maintained, in a bid to deliver maximum uptime for their final customer

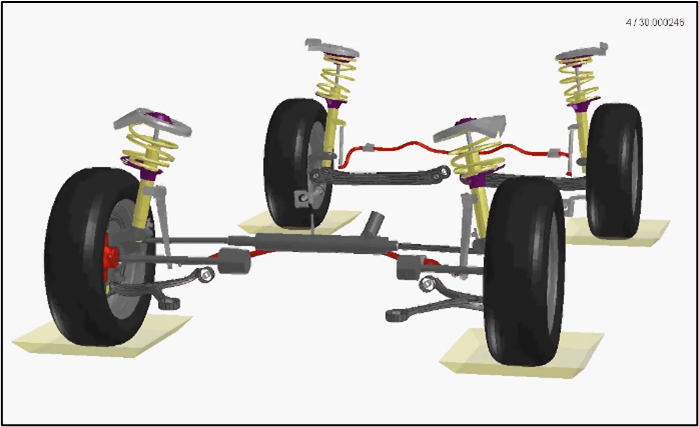

Using our software solutions, you can simulate vehicle dynamics and evaluate operational driving & safety early on, from driver comfort to emergency stops, shutdowns, or tipping safety. Our vibro-acoustic and system modeling solutions equip you to meet requirements related to noise regulations and standards, from interior noise (cabin comfort) to exterior noise (ISO 6395 regulation, engine, and fan noise reduction).

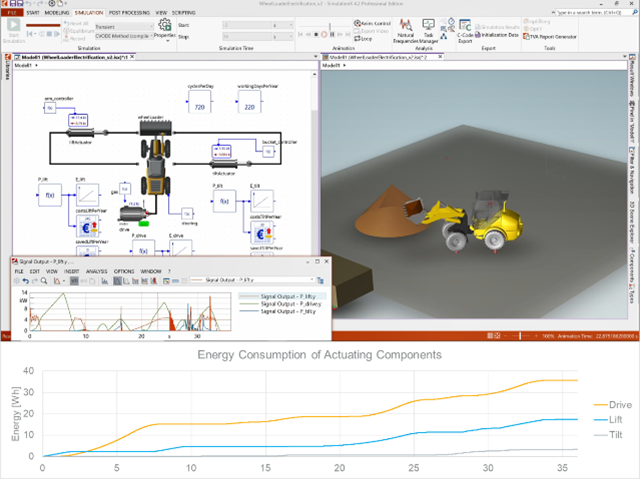

Efficiently Simulate Different Electrification Strategies

In the context of electrification, our simulation software allows for the early integration of power systems' layout and functionalities. They empower design engineers to plan systems, chose the right layout, size components, design structures and integrate for work safety and performance. ESI will support you in displacing physical tests by all-virtual dynamic system tests in multiple conditions, simulating extended work cycles. Speed up product development by working concurrently on a single software platform for energy management, design, and tests of colling systems, functional and performance evaluation. Our software solutions also enable the identification of fault causes and impact analysis, early in product development.

Deploying autonomous systems? Using ESI’s Virtual Prototypes, you can understand complex mechanisms, such as autonomous systems, at all scales - from virtually analyzing stress, reliability, and functional behavior of mechanical systems to assessing influencing systems (such as hydraulics, electronics, and controls).

Virtual Tests for Operational Durability & Misuse Scenarios

Equipping heavy equipment manufacturers with a Virtual Proving Ground, our solutions let you explore fault scenarios, operational durability, and misuse from the early stages of product development thanks to integrated workflows embracing local-to-global behavior and phenomena. Our coupled and chained simulation tools include cutting-edge Model Order Reduction

Anticipate, Optimize and Validate Human-Operations and Ergonomics using ESI’s Virtual Reality Software Solution

Want to feel how it’s like for your workers to build the new machine and how it will feel in operation for the customer? With ESI’s Virtual Reality software solution, you can also test the operability of your final product for given anthropometries, and anticipate issues related to human-machine interactions, that are often discovered too late in the product development process (poor ergonomics, visibility, reachability, or accessibility). Using digital avatars yet realistic physics, you can finally assess product operation, assembly, and service as you would in the real world, minus the risks or the wait. Learn more about our Human-Centric Solution for Products and Processes Validation.