GIFA 2023-第15届国际铸造贸易博览会暨技术论坛| ESI Group

Aynur Haghighi

aynur.haghighi [at] esi-group.com (aynur[dot]haghighi[at]esi-group[dot]com)

aynur.haghighi [at] esi-group.com (aynur[dot]haghighi[at]esi-group[dot]com)

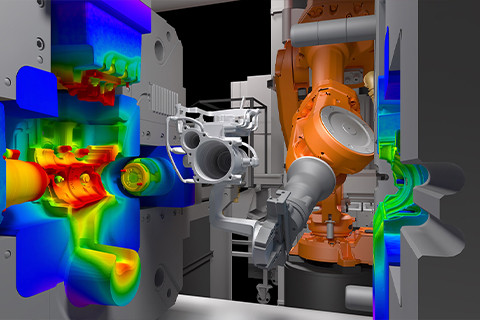

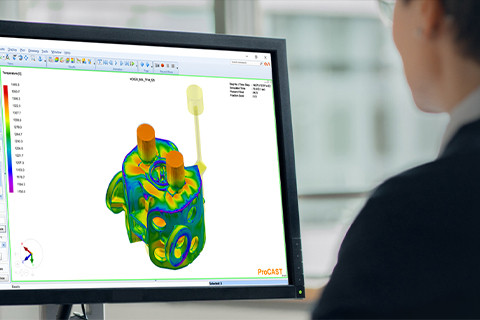

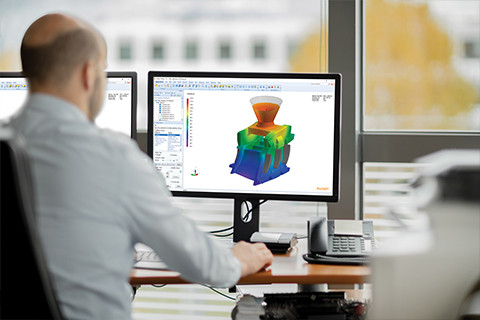

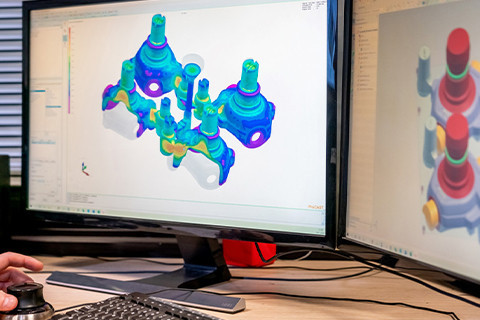

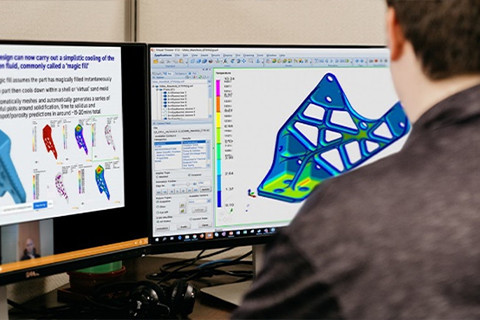

使用ESI的ProCAST铸造模拟软件

让您所有零件一次性铸造成功

你试制的第一批零件终于出来了,但你却发现它们含有不符合质量要求的缺陷。你要在多长时间内回到设计阶段,试图找出问题,并加以纠正?然后你是否有所有的信心,认为该零件最终没有缺陷?铸造模拟可以在开发阶段的早期进行虚拟测试。这是满足最后成功的关键,并防止在废品或后期设计上的资金浪费。

几十年来,工程师们一直依靠ESI的ProCAST进行铸造模拟,作为他们的首选软件,有效地预测铸造的基本情况,并有效地解决变形和残余应力问题。

在GIFA 2023上,请看来自全球ProCAST社区的最新最佳实践。在ESI位于11号展厅的H44展位,我们的铸造工程师将帮助您了解铸造模拟对您工作的作用和价值。

满足所有的质量要求,确保按时交货

有了ESI成熟的 ProCAST铸造模拟软件,人们可以在早期开发阶段预测、分析、测量和量化大多数的铸造缺陷,从而采取措施进行纠正。

我们欢迎你参加演示活动,体验和了解更多的功能,如:

- 专用气孔模型 - 考虑不同合金和工艺对气孔的影响,无论是铸铁的膨胀还是压铸件的强化/压力保持,或者是未溶解气体对微/气孔形成的影响

- 残余应力和变形 -全面跟踪铸造过程中影响最终零件尺寸和工具寿命的不同阶段应力变化

- 微观结构和热处理 - 通过凝固和冷却预测铸件的微观结构演变,从而确定机械性能。可以扩展到分析热处理的影响

- 晶粒结构 - 通过控制铸造工艺条件来计算所需的晶粒结构(DS、SX...),以实现所需的零件性能。ProCAST CAFE模块将细胞自动化(CA)与有限元(FE)热流计算相结合

- 过程优化 - 确定最具影响力的过程变量的敏感性,以达到一套优化的过程变量,如铸造温度、浇注率等。最后在生产车间内对操作工艺窗口进行评估,以考虑工艺变化。