探索 ESI 虚拟样机工具如何 实现卓越工艺与利润最大化

通过沉浸式可视化未来产品与零部件、分析产品集成情况,并综合以人为中心的装配与维护流程,航空航天与国防制造商可以在不牺牲精度、安全性或上市时间的前提下,避免昂贵且受限的物理样机测试。

了解我们的创新航空航天数字解决方案如何助力流程优化与利润提升 —— 点击观看视频,了解更多信息。

从飞机和直升机到太空技术,航空航天行业的 OEM 正面临一个难题:开发产品所采取的方式必须能可靠、安全地应对最不确定的因素,并为乘客打造非凡的飞行体验。与此同时,他们还需要优化供应链,以便从容应对订单激增的局面,将下一代低能耗概念产品快速推向市场,并保证质量和安全。

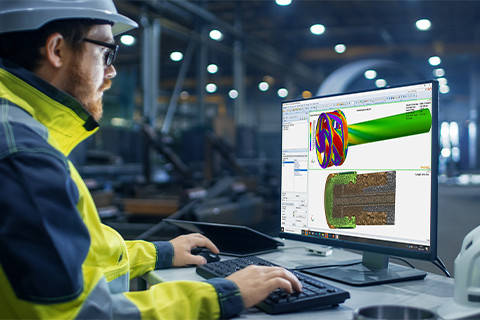

但是,既要获得航空航天新技术认证并演示飞机的行为,又要在上市前和在整个生命周期培养客户对下一代产品的信任感,就好比一个硬币的两面。航空航天业的工程经理已经在引入配备先进仿真工具的产品生命周期管理 (Product Lifecylce Management, PLM) 解决方案,这些工具可以提高工作效率并为决策提供更坚实的基础。但是,如需高效管理这种复杂性,工程师必须以虚拟方式评估飞机成品在真实场景下的整体情况。

性能是制造的关键。这就是 ESI 将 PLM 升级为产品性能生命周期管理 (Product performance Product Lifecycle, PPL) 的原因。我们深信,产品性能生命周期管理是您get it right®的通道。让我们携手开拓飞机研发新局面。

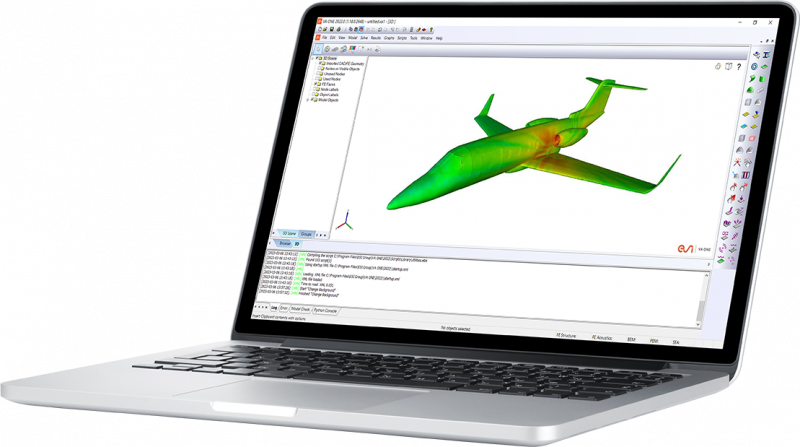

ESI 虚拟样机和 Hybrid Twin™ 解决方案使工程师能够同时利用真实数据和真实物理特性进行虚拟实验。这为工程师提供了更大的自由度,让他们在开发早期就信心十足,一次设计便制造和组装出理想的产品——甚至不用等到切割第一块钢板,而且不依赖物理测试或物理原型,也避免了最终操作过程中出现中断情况。这是真正意义上的端到端数字线程,它将产品设计、制造和服务运营无缝连接,让您在竞争中脱颖而出。

什么是虚拟样机?让我们通过一些示例了解它在航空航天与国防领域中的应用与优势。

受运营挑战驱动,例如克服创新应用的障碍、在不影响其他业务优先事项的前提下实现可持续发展关键绩效指标(KPI)、以及加快数字化转型,航空制造商正在探索实现更高工业效率的新途径。

想了解更多?下载白皮书,探索虚拟原型技术如何帮助您在安全且可持续的前提下,实现航空与空中出行的突破。

一次性完成声学认证

利用您专属的虚拟声学舱测试并认证全新的航空器和航天器设计:一次性通过噪声认证,确保卓越的声学品质。该全虚拟、低排放的测试系统能够在早期发现差异,并在最小化工序、工装和废料成本的同时,测试并认证振动声学性能。

设计安静的eVTOL飞机

EVTOL是一种现代创新飞机,使用电力系统进行垂直悬停、起飞和降落。基于系统的验证方法有助于分析传动系尺寸、飞行控制、飞行动力学和电池尺寸、安全和冷却系统。进一步的振动声学解决方案有助于分析城市地区的外部噪声影响以及内部噪声级舒适性。了解ESI解决方案如何允许eVTOL性能、安全性和满足噪音法规的虚拟设计迭代。

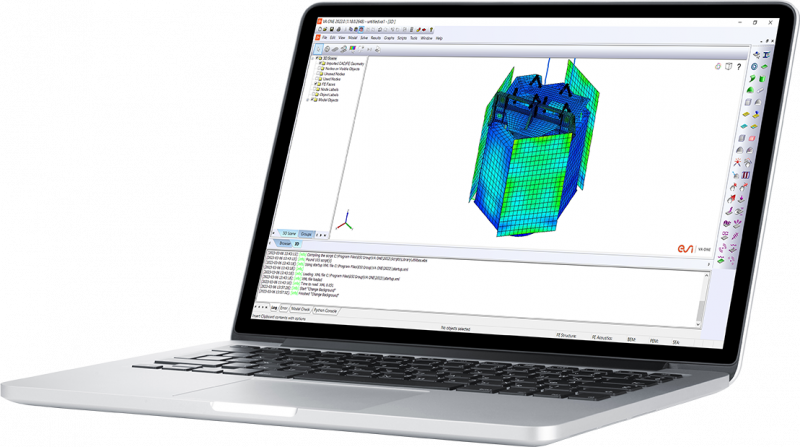

以三维沉浸式原型在工业元宇宙中驱动协同虚拟工作流程

通过创建您自己的工业元宇宙,将工程工作流程提前数月进入生产阶段。无需等待物理原型建造,即可体验尚未实现的飞机设计的真实交互,并且无需出差到同一地点即可与同事协作。从工人和操作员的视角沉浸式探索新型飞机概念,亲身体验制造和维护所需的各项流程。

高精度零件的虚拟制造

通过基于仿真的测试实现材料的最佳性能。借助无限次的分析和实验,深入理解材料物理特性,这在传统物理测试和反复试验中是无法实现的。创建稳定、可靠的制造工艺,以保障产能提升,降低废品成本,节约自然资源,并确保按时交付。

我们的解决方案可以帮助客户按时交付双倍的飞机

航空领域获得广泛信任的虚拟样机技术

在世界各地,供应商、制造商和工程合作伙伴使用ESI的虚拟样机解决方案来设计和优化未来的空中机动性,例如空客、美铝、中航工业、波音、庞巴迪、达索航空、欧空局、通用动力、霍尼韦尔、洛克希德·马丁、MSI-DFAT、NASA、诺斯罗普·格鲁曼、PCC、劳斯莱斯、赛峰、德事隆航空、泰利斯、,联合技术公司等等。