多材料组件是生产具有合理成本/重量比车身的关键。然而,找到合适的材料组合并将其应用于适当的位置、优化几何形状和厚度、设计稳健的制造工艺和选择更优的连接技术是一个挑战。由于组合的数量几乎是无限的,单点数值模拟不足以完成这项工作。

相反,汽车制造商已经开始转向将工程和制造领域紧密结合起来,以便在开发周期中尽早做出正确的决策,并避免使用昂贵的物理样机进行后期校正。

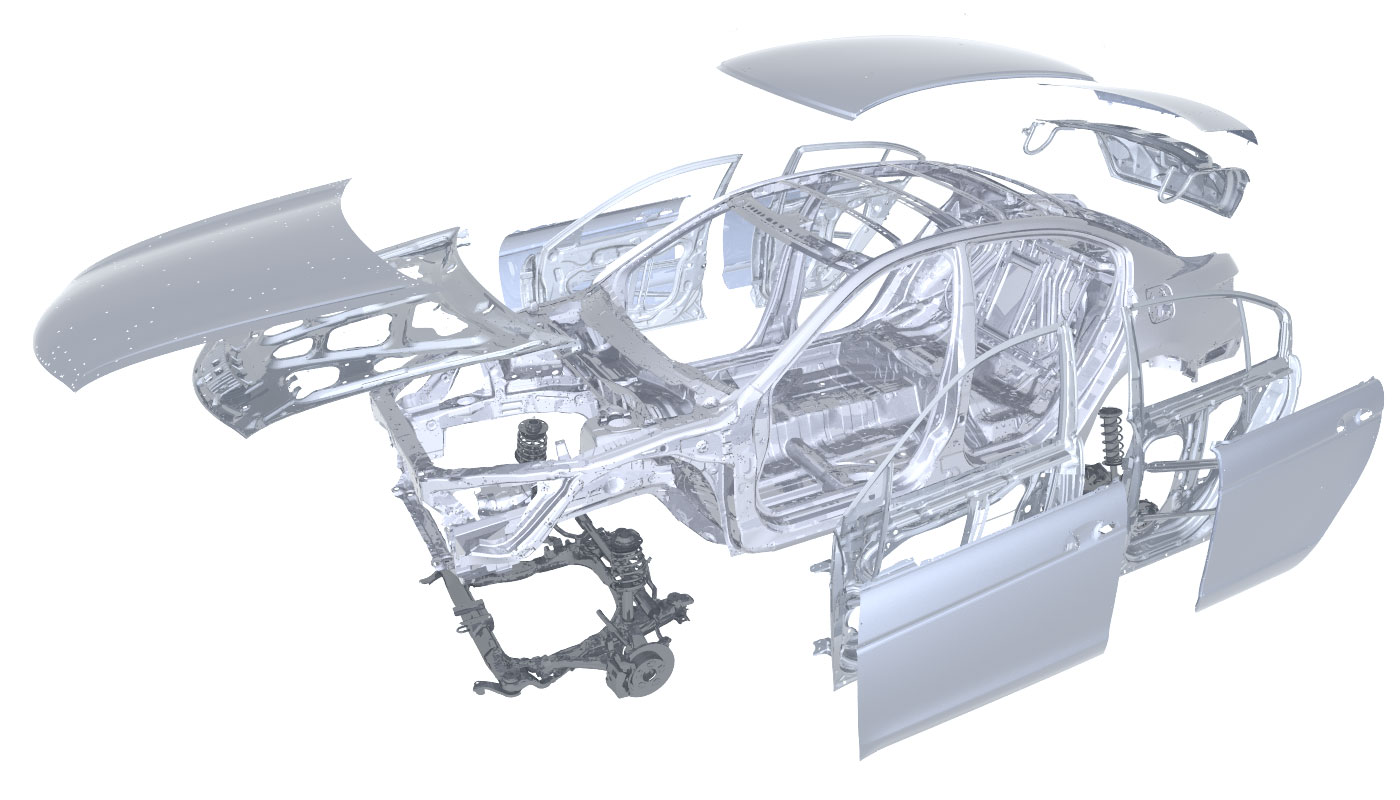

对于大多数基于钢的车身结构,端到端虚拟样机是OEM的既定方法-从连接产品设计、性能和制造工序。一些关键优势包括:

对于大多数基于钢材的车身结构,端到端的虚拟原型设计已经成为整车厂(OEM)的成熟方法——它贯穿了产品设计、性能以及制造工程的工作流程。其主要优势包括:

- 通过对物理规律和应用工艺的精准呈现,提前预测制造、装配和性能,从而更早地对最佳设计充满信心

- 无论采用何种制造工艺(如标准冲压、热成形、铸造),都能对所有轻量化材料(普通钢、高强钢、铝材、复合材料)的制造与性能进行精准验证

-

无限虚拟试验,以寻找最有效的制造工艺,实现具有最佳成本/质量比的装配,同时确保性能正确。

-

减少(并最终完全消除)昂贵的实物理原型和耗时的试验迭代。

最终,端到端的虚拟原型是缩短整体产品开发周期、降低成本并加快量产启动(SOP)的最佳途径,因为它能够确保您的可持续车辆工程、制造及装配工艺的准确性。

探索 虚拟原型解决方案在革新整车车身与底盘制造中的变革力量。本视频介绍了助力从实体测试向虚拟测试转型的解决方案,大幅缩短开发时间和降低成本,同时提升车辆安全性与性能。

观看 Mark Vrolijk 的介绍:

- PAM-Stamp: 用于模拟钣金成形,并预测轻量化设计中可能出现的裂纹等问题。

- ProCAST: 以及如何分析铸造工艺以进行质量控制。

- PAM-Composites: 用于建模复合材料,以兼顾强度与轻量化。

- SYSWeld:用于模拟焊接工艺,以预测质量问题和变形情况。

本视频还讲解了在处理高强度钢、铝部件及复杂铸件时面临的挑战,并进一步介绍了“虚拟价值链”的优势——将制造、装配与性能相连接,以实现最佳最终装配质量、提升安全性,并加快产品上市时间。

多材料装配模拟 如何在整个车辆开发周期中为您提供支持

能够在虚拟样机链的早期引入制造信息对产品开发周期的所有阶段都是有益的。

- 产品设计

- 在迭代由具有挑战性的材料制成的零件时,快速提供可靠的可行性分析和材料成本信息

- 性能研发

- 通过包括成形和装配/连接情况,对“制造”(子)组件进行早期碰撞和耐久性/NVH性能分析

- 制造工程开发

- 为寻找更优工艺路线提供有效支持,以期在公差范围内以预期质量交付无缺陷零件(钢、铝、复合材料)

- 装配工程研发

- 开始在实际的部件几何形状上设立装配过程,包括制造过程引起的形变,并确保最终车身或底盘装配在公差范围内

利用虚拟制造仿真软件设计、制造和组装混合材料组件

让我们一起解决制造和装配问题

多年来,ESI一直在与OEM厂商和供应商合作,创建一个端到端的数字线程,将设计、工程、制造、批量生产和维护中的所有不同利益相关者和活动联系在一起。我们陪同客户将其流程从单点、纯数值模拟转变为端到端的虚拟样机——确保他们在第一时间正确完成单个零件的设计、制造和装配流程。这是设计和制造可持续移动设备的多材料解决方案的基础。

从单点数值模拟转移到端到端连接的虚拟样机工作流有什么好处

简而言之:快速培养对新材料和制造技术的信心。这一切都是关于在工程范畴内预测制造过程,更早更快地实现优化设计,同时最大限度地减少对物理样机的需求。这使我们的日常工程研发和制造实践更加可持续的关键。

下载白皮书,了解OEM工作流如何从单点数字材料和过程模拟转变为端到端连接的虚拟样机工作流。

巨型铸件的虚拟建模

巨型铸造(Mega Casting),也称为超大铸造(Giga Casting 或 Hyper Casting),是一种制造大型铝制汽车零部件的颠覆性方法。它预示着汽车将更加轻量化和高效。然而,重大创新也伴随着高风险。通过对巨型铸造的每一个环节进行仿真,您可以在投入大量模具费用之前发现并解决潜在问题。这有助于优化设计,确保生产顺利,使未来汽车制造更加顺畅。