了解 ESI 虚拟原型软件如何助您打造安全、可持续且高效的机械设备

在建筑、农业和采矿等重工业领域,制造商在产品设计、生产、组装和运营过程中面临诸多挑战。

如今,运营方要求产品在整个生命周期中都能实现最佳性能,强调从初次制造到运行和维护的安全性与生产效率。目标是交付更安全、更环保、更高效的机械设备,同时通过高效的企业级协作管理成本并满足交付周期,并确保设备在严苛环境下的长期性能。这正是虚拟原型技术的价值所在:通过虚拟环境,改变工程师设计与测试新产品及制造工艺的方式。

以虚拟现实驱动的安全高效、以人为本的操作

打破设计、制造与维护之间的壁垒。缩短交付周期,以可控的质量和成本满足投产需求。以以人为本的方式提前验证产品集成。在工厂核心环节整合人为操作。预测并优化人机交互,在提升生产效率的同时保障工人安全。及早制定以人为本的维护流程,以确保维护安全、加快进度并降低成本。尽早实现安全高效的服务操作。

虚拟原型技术:工程师超越期望的关键

面向现实的设计

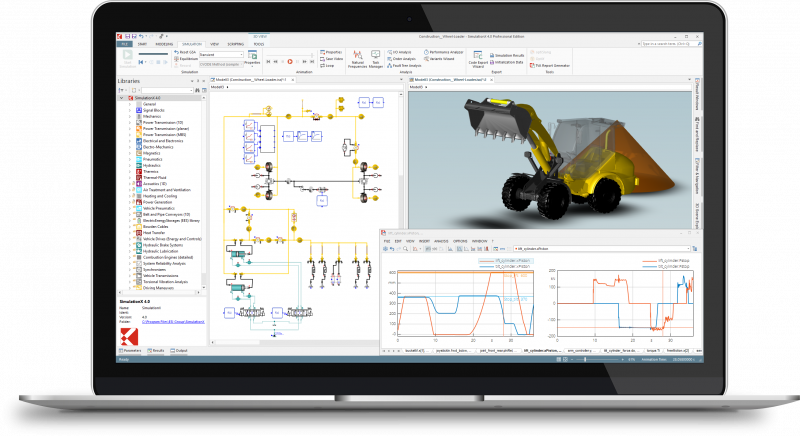

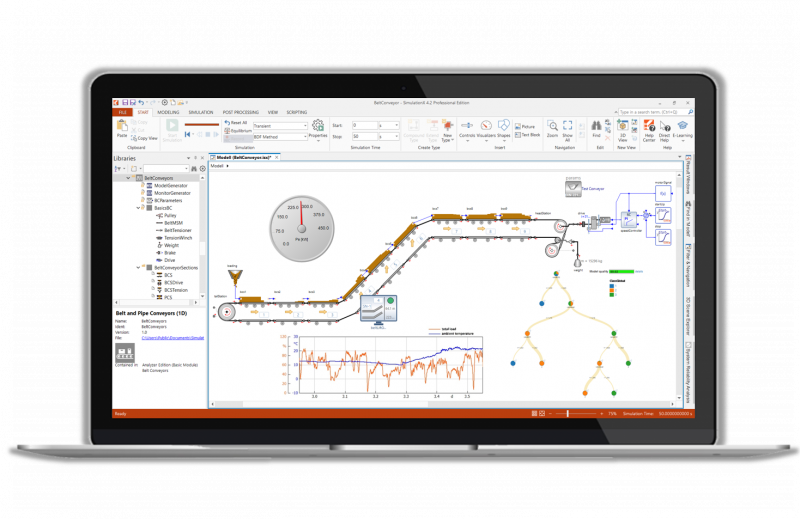

及早获得对产品全生命周期性能的信心,即使在最严苛的使用条件下也能如此。应对机电一体化和复杂系统日益增长的应用需求。通过明确系统设计、尺寸匹配、测试及可靠性预测,实施最新的电气化与自动化技术。预测使用故障和误操作场景。规划产品的操作耐久性与防误用设计。在崎岖地形中实现快速且安全的驾驶,包括车辆动力学与稳定性分析。研究机械设备的动态行为,包括紧急制动与停机情景。检查防倾覆安全。实现最大生产效率,并延长产品使用寿命。

虚拟试验场

设计安全、环保且高效的机械与设备。减少实际测试与原型数量。在法规不断变化的情况下,实现产品预认证。应对涉及多个领域的产品性能挑战,从噪声与声学到耐久性。确保操作人员的安全与舒适为首要考虑。评估操作人员在工作中可能遇到的冲击与振动。满足内外部噪声与声学的法规要求与目标。确保最佳的可视性、可达性与可操作性。

通过虚拟原型实现零缺陷目标

提升生产效率与产量。通过追求生产零缺陷,提高生产投资回报率。保障产品质量。模拟从铸造到板金成形、复合材料成形、增材制造、焊接、连接与装配的各类制造工艺。优化工艺参数,即使面对最复杂的产品形状和工艺。在新业务投标中领先竞争对手,同时通过快速简便的新工装及零件生产报价确保盈利能力。无需为新工装、零件和组件制作实体原型。提前预测并加快投产进度。满足要求并保持在可接受公差范围内。深入理解材料物理特性,实现承诺的产品质量。告别废品。提升生产工厂的可持续发展水平。

以混合孪生体为基础,实现零停机目标

为客户提供最大运行时间。从预防性维护转向预测性维护、诊断与预测。拓展思维:从传统 PLM 转向 ESI 的产品性能生命周期(Product Performance Lifecycle)。构建专属混合孪生体,结合材料物理特性与传感器收集的数据。在正确的时间做出正确决策,保护您的资产。

新电子书:用虚拟原型开创创新之路

了解 ESI 的虚拟试验场、虚拟制造工艺链及协作工作流解决方案,这些技术助力清洁、安全、高效的重型机械设计、测试与制造。探索同行工程师如何在重型机械企业中受益于数字化方法,以及 ESI 的虚拟原型仿真软件如何帮助您实现无妥协的创新。立即获取我们的最新电子书。

重型工业中的虚拟原型技术受以下企业信赖

全球各地的供应商、制造商和工程合作伙伴都使用 ESI 的解决方案来设计和优化重型机械,例如:ABB、AP&T、阿塞洛尔·米塔尔(Arcelor Mittal)、博世力士乐(Bosch Rexroth)、卡特彼勒(Caterpillar)、CNH、Epiroc、富士电机(Fuji Electric)、Gabler、日立(Hitachi)、约翰迪尔(John Deere)、永恒力(Jungheinrich)、小松(Komatsu)、利勃海尔(Liebherr)、Lenze Drives、三菱电机(Mitsubishi Electric)、Palfinger、普茨迈斯特(Putzmeister)、Romonta、西门子矿业(Siemens Minerals)、西门子大型驱动(Siemens Large Drives)、Tenova Takraf、联合技术(United Technologies)以及 Voith Paper 等。