Worldwide

3pm CET / 9am ET

1 hour

From construction & mining to agricultural and forestry machinery, manufacturers not only face challenges related to product design, but also product manufacture, product assembly, and even product operations. Their aim is to deliver safer, cleaner and more productive machinery and equipment. Doing this at controlled cost and within set lead times. While committing to maximum productivity and uptime for the toughest usage conditions.

Join us for a webinar series to learn more about how to achieve early confidence in product performance, realize efficient enterprise-wide collaboration and ensure first time right physical prototyping.

4 Webinars to Dive Into the Digitalization of the Heavy Industry

Deliver Safe, Clean, Productive Machinery & Equipment

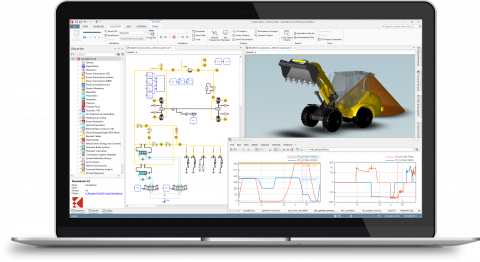

Digital Transformation of your Product Performance Lifecycle,through the virtual prototyping of key product and process validations, accelerates product development processes. Establishing a Virtual Proving Ground, Pilot Assembly Hall, and Virtual Service Maintenance Garage to assess upcoming products requires more than a series of disconnected, discrete simulations or deterministic analyses.

Join us in our upcoming webinar series, where we will address how the Heavy Industry can design, test, and validate upcoming products for operational comfort & Safety, validate the integration of power, control, and mechanical systems.

Ultimately enabling them to deliver safe, clean, and productive new machinery & equipment designs proven to meet the highest quality requirements and lifetime performance for the toughest usage conditions.

Electrification of Heavy Machinery: Challenges & Solutions

ACCESSIBLE ON-DEMAND LENGTH: 1h

Sustainable electrification for industrial and off-highway machines

Sustainability is a common motivation of electrification in industrial and off-highway machines. Electrification impact on sustainability can be viewed from several perspectives; reduce emissions and carbon footprint, lower cost of ownership, systems simplification or optimization, reduction/reconfiguration of physical footprint, or merely engineering a MORE DESIREABLE PRODUCT, to list a few.

However, converting traditionally combustion powered industrial machines and vehicles is not a matter of simply removing the combustion engine to be replaced with batteries and electric motors. Engineering these novel products for delivering customer required outcomes requires holistic evaluation of potential machine performance and efficiency, as well as anticipation of product integration, assembly, and service requirements.

In this webinar we address engineering challenges and questions that arise in the system specification and modelling of electric commercial vehicles and industrial machines. Ranging from systems modelling of the electric/mechanical systems that power the machines to the human-centric validation of the assembly process requirements and service maintenance procedures for these yet to be realized or replicated product variants

On-Demand

Operational Safety & Comfort

ACCESSIBLE ON-DEMAND LENGTH: 1hDelivering successful new products for the construction, mining, and agriculture industries requires delivering machinery products that are Safe, Clean, and Productive. However, informing the design and engineering decisions required to assure success without access to the actual product is a challenge remaining in most companies' digital transformation.

Many deterministic methods of testing and evaluating products are discrete simulations of specific conditions meant as a proxy to real world conditions. While these types of tests are highly illustrative and better than not performing the tests at all, they still occasionally fall short of what is learned when those products are rolled out to actual construction sites, farms or forests, and mines.

Join us on April 8th, during a webinar where we will discuss how leading enterprises are applying virtual prototyping to gain necessary holistic product analysis insights. Ultimately assuring the delivery of Safe, Clean, and Productive machinery for their customers mines, farms, forests, and construction sites.

Key Topics and On-Demand Access

In this webinar you'll learn how to:

- Identify methods to evaluate & improve operational safety during operation

- Evaluate product dynamics and stability in rough terrain

- Assess machine behavior in Emergency Stops and Shutdown

- Ensure Operator Comfort, interior and exterior noise regulation

- Verify operator Visibility, Reachability, and Accessibility long before product availability

Human Centric Product & Process Validation

ACCESSIBLE ON-DEMAND LENGTH: 1hThe digitalization of product design and engineering is well accepted and practiced in most Heavy Machinery & Equipment engineering organizations—especially for those design attributes which have quantifiable standards and limits. Although when it comes to ergonomics and impact of human factors, until people can walk around, climb on, sit in, and take assemble-disassemble-reassemble the actual product, we often don’t know what to assess and what is acceptable or not.

Operating, assembling, or servicing a first-of-its-kind product or implementing new methods, we often can’t know what it is that we don’t know about that product— operators will face these challenges when interacting with products they have yet to experience. For this reason, assembly process planning has long relied on pre-production prototyping and assembly piloting to allow workers to experience and evaluate proposed assembly processes and tooling. Similarly, service and maintenance planning are most often based on previous products history or require service teardown workshops conducted on the pre-production prototypes.

Access our on-demand Human Centric Product and Process Validations to see how leading enterprises conduct product integration, assembly process, and service method validations in Virtual Reality.

Key Topics and On-Demand Access

In this webinar you'll learn how to:

- Discover Human-Centric Product & Process concerns addressable with Virtual Reality

- Identify Product Integration and Packaging issues through application of Immersive Reviews

- Recognize how virtual assembly and service process validations can be performed

- Find opportunities for virtual collaboration between distributed teams & suppliers

Machine Performance & Productivity

AVAILABLE ON-DEMAND LENGTH: 1hAs digitalization of engineering validation workflows accelerates, the replacement of physical prototypes and pre-production products has escalated possible gaps in product development. Namely, the lack of physical testing at the product proving grounds to inform product development. For products with higher capital costs, lower planned production volumes, and diverse applications, this raises the potential that product performance attributes might be tested in less than realistic conditions. Evaluating the potential durability of future products operated in rough terrain or even misused is not only financially impractical, but increasingly logistically improbable.

Implementing Virtual Proving Grounds, where analysis of disparate simulation methodologies can be considered more holistically between Model Based Systems Engineering, non-linear performance analysis includes manufacturing impact, is an emerging trend among leading enterprises. Conducting “hands-on” product evaluations of the product virtually, can inform engineers to product requirements similar to interacting with pre-production prototypes or mock-ups.

Access this webinar where we introduce more of the building blocks required for comprehensive Product Performance Lifecycle management.

Key Topics and On-Demand Access

In this webinar you'll learn how to:

-

Holistic Product Validation (Combining System, Performance and As-Manufactured Analysis)

-

Virtual Testing of Operational Durability & Misuse Scenarios

-

Managing the Product Performance Lifecycle from Design for Reality to Operational Performance

-

Process Integration and Test Automation through Model Based Systems Engineering