为满足激进的车辆项目在时间和成本方面带来的挑战,原型样机的数量必须减少。新车设计,尤其是电动汽车,与传统的汽车设计相去甚远,必须准备好满足不断发展的法规要求。汽车设计师必须更快地设计新概念,同时提出创新解决方案来应对电力交通的挑战。这对设计团队来说是一个巨大的障碍,他们必须采用新的数字方法,同时满足或超过性能要求。

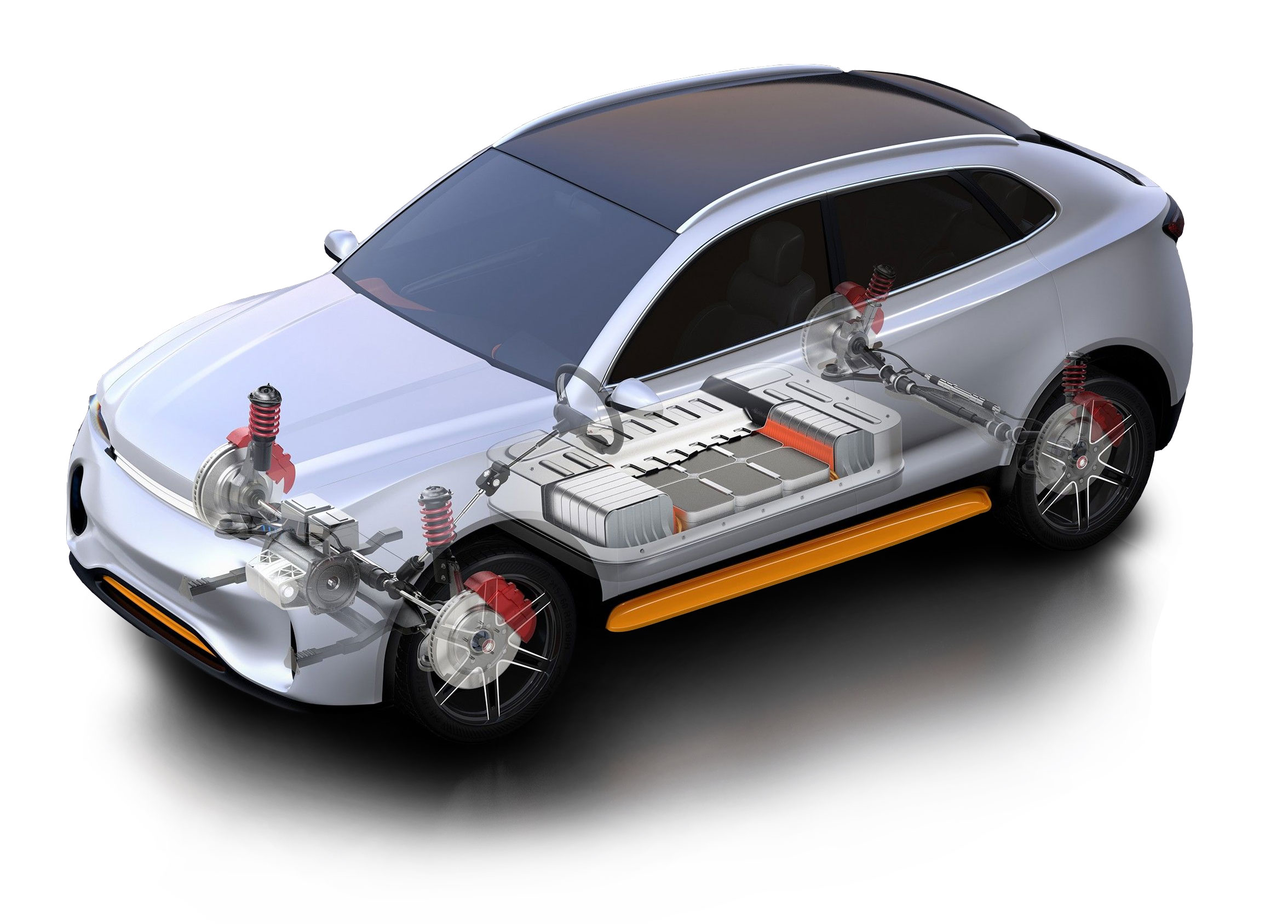

在电动汽车中引入电池舱需要使用新的模拟过程来预测设计决策对最终产品性能的影响。蓄电池对车辆总重量、质量分布和碰撞响应的影响必须符合最近快速发展的电池安全法规。

为了满足这些需求,工程师必须放弃传统的迭代“设计-测试-修复”流程,在设计周期的早期部署数字解决方案,以控制与创新相关的风险。使用最先进的模拟方法,即虚拟样机,工程师可以用虚拟替代品代替物理测试,加快开发过程,并在开发周期的早期预测潜在问题,从而平衡与创新相关的风险。为了遵守特定国家的法规,汽车OEM厂商必须采用一个开发周期,该周期可以快速准确地评估设计的性能,并随着这些法规的发展而适应新的期望。

ESI的电动车安全开发虚拟试验场代表了一个统一的环境,在建立一个物理验证原型之前,就可以对设计进行评估和虚拟鉴定。也可以准确呈现具有挑战性的物理测试,如正面小重叠碰撞,包括较新的复合材料或混合材料结构和传统钢结构的结构变形和断裂。安全气囊设计可以进行虚拟工程设计,电动汽车可以进行电池临界过水和进水测试以及电池碰撞模拟。

为了满足这些需求,工程师必须摆脱依赖物理模型的传统“设计—测试—修正”迭代流程,在设计周期的早期就引入数字化解决方案,以控制创新带来的风险。借助最先进的仿真方法——虚拟原型,工程师能够用虚拟测试替代物理测试,加快开发进程,并在开发早期预测潜在问题,从而平衡创新风险。为遵守各国的法规要求,汽车 OEM 必须采用能够快速准确评估设计性能的开发周期,并随着法规演变及时调整以满足新的要求。

虚拟样机是我们快速实现SEAT高质量发展并实现盈利的途径。ESI在数值模拟和材料科学方面的软件和专业知识为我们带来了所需的条件,以减少以前物理原型和测试车辆的排放和报废,并仍然获得欧洲NCAP五星级评级。这对于成功实现我们的绿色协议目标是非常宝贵的,也是至关重要的。

Xavier CastilloSEAT

了解用于虚拟性能仿真的VPS软件

确保对乘员和路面弱势人群提供最大的保护,并在上市前只需进行一次监管性的物理验证测试,就能在第一时间获得认证。了解利用虚拟测试开展工作的好处,以便在第一时间获得正确的创新设计,同时消除用于碰撞分析的物理原型测试。