Casting simulation can help your foundry meet its commitment to parts quality and deadlines while increasing profitability by avoiding late design changes, and reducing scrap rates.

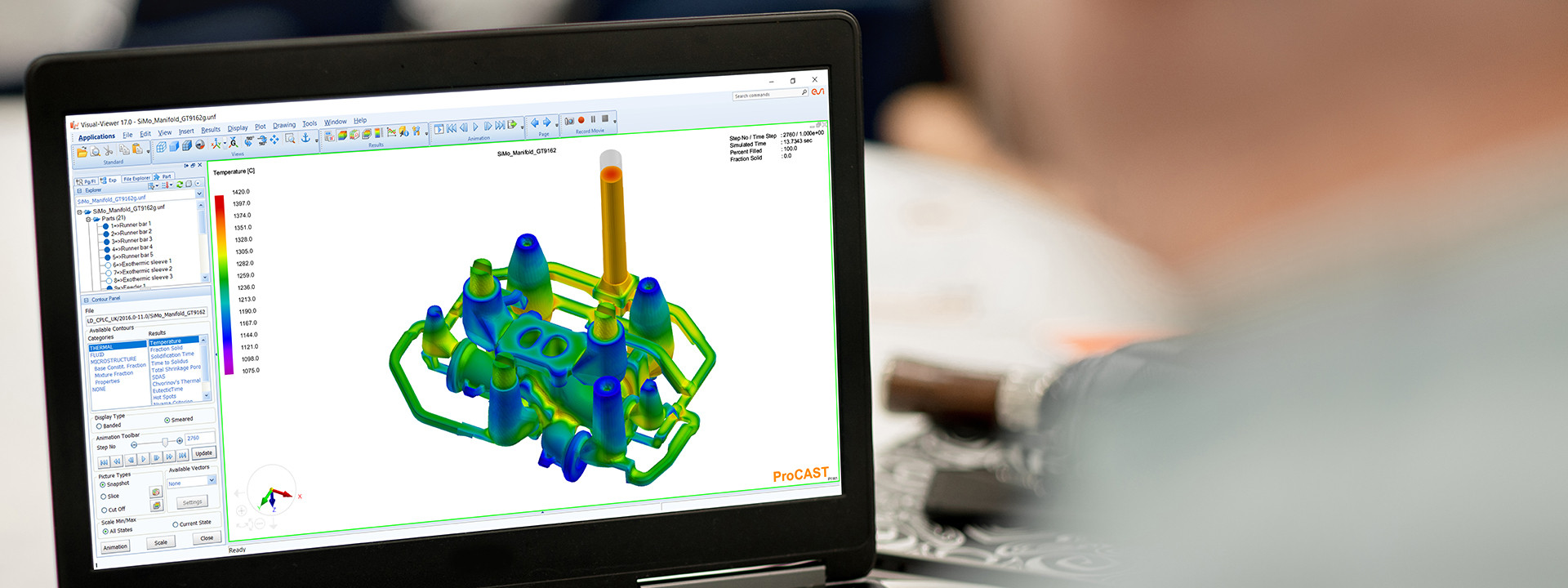

ProCAST enables leading cast parts manufacturing companies to virtually test their manufacturing processes as early as possible, so they can “get it right” during production trials.

With its Finite Element technology, it also predicts complex issues like deformations and residual stresses and comprehensively addresses most castable alloys and most casting processes including die casting (HPDC including Hot/Cold/DCM, LPDC, CPC, GDC/PM, Tilt/Rotacast, Vacuum, Semi-Solid), sand casting, investment casting, and the multiple variants associated with these processes.

Our casting simulation software ProCAST enables foundries to:

- Predict, analyze, measure and quantify the most common casting defects in the earliest stages of design

- Simulate the entire process – from furnace to final casting to capturing and tracking all physics

- Automatically determine the casting part's best process window to reach the final quality goal through Design Of Experiments (DOE), Optimization & Process Robustness analysis

- Co-design parts with their customers, to ensure the best castability

- Select the right HPDC machine for producing specific parts

Featuring:

- Automatic shell mold generation

- Modelling wrapping configuration

- Radiation with shadowing effects

- Grain structure prediction

- Residual stresses prediction

- Final distortion prediction

Download our ProCAST brochure to find out more!

How Customers Succeeded at Part Manufacturing

- Kovolis Hedvikov relies on advanced numerical simulation with ProCAST to prolong die fatigue life

- Azterlan uses ProCAST during all stages of product development and optimizes their processes

- MCS Facchetti uses ProCAST for feasibility analysis to reduce final part cost

Find out more about Casting Simulation

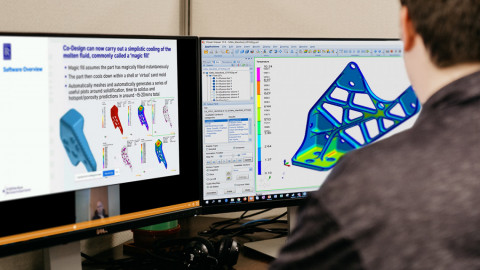

Co-Design for Casting_ A bridge between Product Designers, Buyers & Manufacturers

How do Rolls-Royce engineers make sure their designs are fully castable?

Smart Manufacturing - Casting Solution for Sandcasting to keep up with production and design during Pandemic

For Nissin Kogyo, ESI ProCAST is an Indispensable Tool for Assuring Production Quality