随着需求和市场压力不断增长,OEM 需要努力满足的标准也越来越高。工程设计为生产和服务奠定了基础,因此,工程设计团队必须认识到人与所设计的产品及其工艺之间的相互作用,这样才能保障生产和组装的便利性,但如果存在以下障碍,并不一定能找到妥善的解决方案:

- 缺乏能够在生产计划(人体工程学、安全性、效率、可行性)早期有效预测并减少人工成本的时间和能力

- 没有现成/易得的实际设备可基于标准化和本地化考量来发现并验证生产方案的工艺可行性(产品、流程和资源之间的取舍)

- 难以帮助包括供应商在内的多学科团队有效体验、验证和交流生产工艺要求和解决方案概念的意义。

- 没有现成的虚拟试验环境(独立于试验或生产线)可用于发现、斟酌和验证工艺创新与改进

- 在实体生产线上线之前,可供装配工艺探索及生产人员推动改进的环境有限。

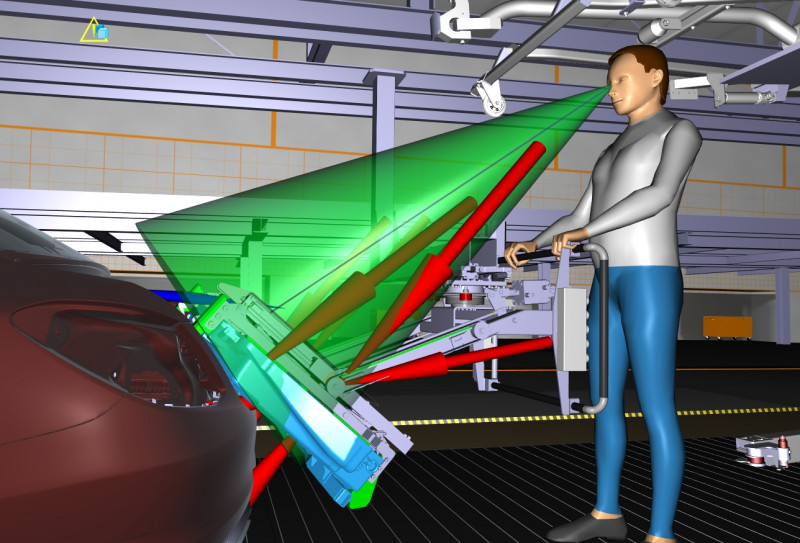

借助虚拟现实技术,工程团队可基于以人为本的工艺交互,体验、验证组装和维护要求并开展交流。最终,可在完整环境下针对拟定设计进行体验式评估,从而大幅降低后期装配风险、提升效率,进而推动增产以满足关键产品目标。

With Virtual Reality, engineering teams can experience, validate, and communicate on assembly & maintenance requirements in a virtual environment taking into consideration the human-centric process interactions. Ultimately, enabling realistic experience-based evaluations of proposed designs in their complete context allows for a significant reduction of future assembly risk, increasing efficiency toward production ramp-up that meets key product targets.

以人为本的过程验证和产品整合的好处是什么?

我们的软件解决方案提供了与产品和资源"真实的 "互动体验,使工程团队能够在产品开发的早期评估决策,而此时仍可进行设计变更,而不会产生巨大的成本或延误。这样一来,汽车OEM就可以从昂贵的物理原型中解放出来,实现他们的可持续发展目标,同时避免后期生产的不确定性。此外,身临其境的虚拟环境还实现了协作工程,以及在产品开发的每一步中体验、验证和沟通设计决策的方式。

如果你想减少设计迭代,想想你可以避免的各种障碍吧!

- 可视性 | 尽早发现设计是否会给操作员带来盲点

- 可达性 | 不同的操作人员是否能够接触到控制装置?或者更换零件?

- 可访问性 |操作人员获得他们需要东西的便利性?

能将你的工程研发工作流程向前推进数月的虚拟现实软件在汽车行业的主要应用是什么?

在将电动汽车、自动驾驶汽车和互联网汽车推向市场的竞赛中,OEM厂商正面临着一个困难的难题:如何提高现有模式的效率,并使其下一代概念更快地转换成产品进入市场。汽车制造商明白,他们必须利用数字解决方案来加快新汽的交付,保持成本下降,并避免后期发现任何不足和欠缺。像FCA、沃尔沃GTT、巴西大众和丰田这样的原始设备制造商--以及他们的扩展企业--都依赖于虚拟现实软件。

VR软件如何在网络时代使企业沉浸式可视化他们未来的产品和部件,分析产品集成,并引入以人为本的流程,以推进他们的产品开发周期?让我们来看看领先的汽车公司的一些具体例子。

确保产品顺利整合

ESI 配备 IC.IDO,可针对最终装配或服务维护等流程提供以人为本的产品和工艺验证。这种沉浸式解决方案可推动多学科团队评估、合作和攻克新产品与工艺在未来为工厂带来的难题。无论是个人还是团队,也无论是在同地配合还是远程协作,都可以在生产车间开始建模前探索数字设计并开展交流,以发现潜在风险、评估改进空间和纠正措施。

我们的虚拟现实解决方案支持对包装和空间要求、结构设计和交互的数字化评估,无论是对运行中的产品还是对装配、服务和维护过程的评估。工程师们可以从具有真实物理特性的沉浸式场景模拟中获得好处,他们还可以在真实的空间体量和实时的情况下模拟接线、布线和软管的行为,使团队有能力发现软管和电线的纠缠、捆绑或挤压的问题,以避免在操作中出现干扰、碰撞或磨损。

以下是虚拟现实可以带来的优势:

在你加紧生产之前,你如何评估一个特定的操作需要多少个操作员?你如何验证需要多大的空间?你如何评估所需的加工时间?

我们的客户Volkswagen do Brasil不仅成功地在短短10个月内开发出了新的Nivus,而且他们还通过使用IC.IDO在生产前很早就预计到了装配步骤。

尽早安全地计划您的装配操作,而无需等待实物模拟:代表不同人体测量学的数字人体模型或人体模型,让您在生产之前就能评估人体工程学、操作员的可视性、可及性和可访问性,以确保安全和高效的装配过程。

得益于虚拟工作空间中的真实物理属性,工程团队有信心验证工具情况;他们预测单元布局并优化,确保在开始生产和产能爬坡阶段之前满足所有要求。

预测维护和服务过程

- 在产品开发流程早期就发现和解决复杂的设计问题,此时的修复成本相对较低

- 减轻设计对于昂贵的物理原型和试验活动的依赖

- 促进零散分布的团队开展多学科协作

- 在应用新设计、工具和程序之前,先行开展人体工程学分析

- 优化工厂车间工艺和制造单元布局

- 在将产品投入真实环境之前,于流程环境中体验产品

将 IC.IDO 集成到产品和工艺开发过程中后,除了可以提前体验并及时攻克组装、运营或维护操作难题,规避与此相关的成本外,用户还可节省制作物理原型所需的时间和成本。

使用我们的解决方案,您将能够评估操作员舒适性、安全性和效率的各个方面。一旦场景建立,几乎不需要花费任何时间就可以戴上VR眼镜来验证程序和流程,对零件之间的碰撞和受阻的安装/拆卸路径进行物理逼真的处理。