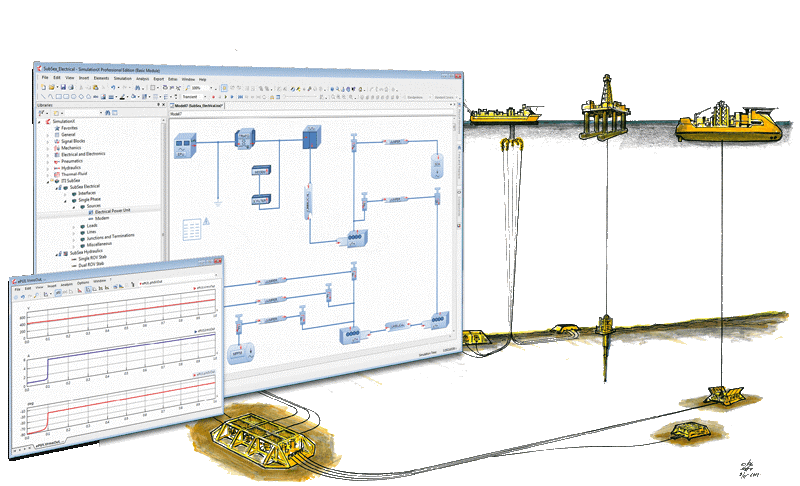

Most of the world’s remaining oil and gas resources lie offshore and in water deeper than 2,000 meters. Extreme subsea conditions require that all components meet a very high level of reliability. Virtual simulation of such machinery helps achieve system reliability and protects both your investment and the environment.

-

Early identification of weak points and degradation trends

-

Eco-friendly and safe extraction and processing of natural resources

-

Avoid production loss

-

Ongoing system verification and optimization

-

Asset integrity and risk assessment

Simulation Solutions for Oil & Gas Applications

System integration is our core competency. Achieving high performance for all depth is our common development goal. System simulation with our software, SimulationX, is the tool for you. ESI’s engineers, together with the international offshore/subsea engineering consultancy, Agito, are here to support you throughout your entire development process of subsea and offshore technology. Model your own multiphysics systems and conduct virtual tests with SimulationX.

The longstanding partnership between ESI and Agito, two established experts in their fields, embodies the perfect combination of system simulation and engineering expertise in the oil and gas industry. This close collaboration has yielded tailor-made model libraries and highly precise, ready-to-use component models. These models are specially designed to meet the requirements of the oil and gas industry for general and deep water (subsea) applications. When combined with extensive system knowledge, SimulationX can conduct a system trend analysis on an operational 'Brown Field' development, identifying system performance degradation, and reducing the risk of production loss. These losses may also represent unacceptable levels of risk to people and the environment.

Here are some examples of how you can use System Modeling:

-

Multidisciplinary modeling of heave compensators and 'launch and recovery systems' (LARS)

-

Model-based development of innovative, high-tech plants and system solutions for the exploitation and production of energy resources in an environmentally friendly way

-

Analysis and evaluation of the dynamic behavior of components and systems used for the production and distribution of oil and gas

-

Real-time virtual test of systems for oil & gas production, covering systems for drilling (top-side and subsea), production (top-side and subsea), and subsea construction and process equipment

-

Perform reliability analyses and establish Fault Tree FTA of an oil & gas system to identify the weakest link and bottlenecks in the system