ESI Presents Leading Casting Simulation Software ProCAST at CastExpo 2016

Paris, France – April 5, 2016 – ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, announces its participation at CastExpo, 16-19 April 2016 in Minneapolis, MN, USA. Sponsored by the American Foundry Society (AFS), CastExpo is the largest metal casting trade show in North America. ESI will showcase on booth 1915 its leading casting simulation software, ProCAST, which addresses a large number of casting processes for diverse metals and alloys. Developed over the past 25 years, ProCAST has helped foundries, big and small, improve cast part quality, reduce manufacturing defects, and lower scrap rates.

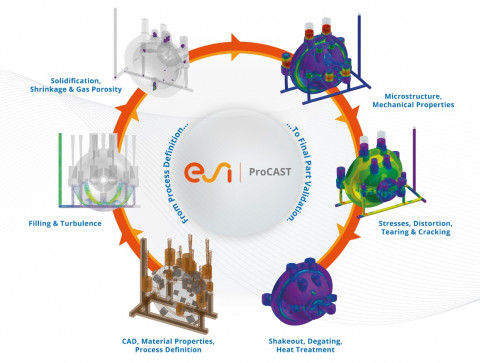

ESI ProCAST is a versatile, precise and comprehensive casting simulation solution, enabling foundries to tackle easily both typical and complex casting issues. Using ProCAST, manufacturers quickly understand and fix casting defects caused by shrinkage, gas porosity, mis-runs, inclusions, and a variety of other defects linked to microstructure and mechanical evolution. Based on powerful Finite Element technology, ProCAST expands the scope of typical casting simulation to stress evaluation that predicts distortion, residual stress, hot tearing and cracking; addressing both the casting process and subsequent heat treatment. The software covers typical casting processes from sand casting to die casting, investment casting and permanent mold casting. Other less common casting processes or casting-related processes also benefit from ProCAST modeling. These include semi-solid and core blowing processes, centrifugal casting, lost foam, and continuous casting.

ESI ProCAST also targets the typical foundry concerns of filling, solidification, and porosity prediction and provides a simple and efficient analysis setup without compromising the accuracy of the evaluation. It helps foundries reduce costs and lead times and is used at all stages of mold and process development and for cast part quality assessment.

Meet ESI at CastExpo!

Requiring minimal training, ESI ProCAST meets the needs of factory shop floor technicians as well as it does for experienced casting process engineers. At CastExpo ESI’s technical representatives will run demonstrations of ProCAST and explain simulation capabilities through case studies. Join ESI on booth 1915 to meet our Technical Engineers and to find out more about Casting Simulation.

Sam Scott, ESI North America, will deliver a technical presentation entitled “Effective Gating for Copper Alloy Sand Castings” in the technical session “Quality Pouring Practices to Achieve Clean Castings” during the Copper Alloys track, on Saturday April 16, 2016 at 9:15 AM. Sam will demonstrate gating and risering strategies to obtain high quality castings – targeting methods applicable to copper, but also valid for a wide variety of other alloys.

Read about how ESI customers use ProCAST

Connect with ESI on LinkedIn, Twitter, Facebook, and YouTube

ESI Group – Media Relations

celine.gallerne [at] esi-group.com (Celine Gallerne)

+33 1 41 73 58 46