DGA Aero-Engine Testing is Developing a Digital Alternative to Traditional Test Benches with ESI's SimulationX

Paris, France – September 25, 2018 – ESI Group, leading innovator in Virtual Prototyping software and services for manufacturing industries, announces its collaboration with DGA Aero-Engine Testing in the development of a virtual test bench for aircraft engines in flight conditions. DGA Aero-Engine Testing (or DGA-EP) is a non-profit public body, part of the Test and Evaluation capabilities of the French armament procurement agency. Aircraft engines, for both civil and military applications, are tested in DGA-EP facilities to verify their performance for given applications. These tests are an integral part of the engine certification process. This project leverages SimulationX, ESI’s solution for system simulation, to deliver a major technological advance that will benefit the DGA in terms of resources, deadlines and budget.

DGA Aero-Engine Testing or DGA-EP – an entity dedicated to all types of aeronautical thruster tests – has a wide range of test facilities. It designs and carries out tests of aerobic aeronautical engines, their components, assemblies and sub-assemblies and associated equipment under simulated flight conditions, including icing conditions. The DGA-EP site is currently the largest center of its kind and houses nearly all high-altitude caissons in Europe. To optimize the preparation of its tests and the training of its operators, the entity launched the SIMATMOS project in 2012, with the objective to implement a virtual test bench, which will eventually be used to train its operators, check the feasibility of the tests and predict the performance of the testing installations.

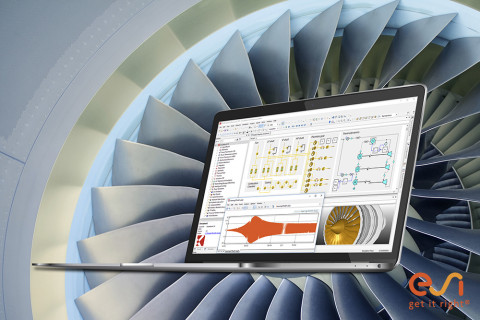

Following a public tender, DGA-EP chose ESI’s system simulation solution to model the installations. The solution SimulationX empowers them to create Virtual Prototypes of the engines, and to test them virtually under real flight conditions. In addition, the open and adaptable environment provided by SimuationX will enable connections to a flight simulator in the future.

Laurent Porsain, Test Process Manager at DGA-EP, in charge of the SIMATMOS project, comments: "This success is part of our wider transition to Industry 4.0. Our objective is to take advantage of exceptional digital solutions to complete more numerous and more comprehensive tests, to work collaboratively and to train our teams. We aim to do this at a lower cost and before the final physical test, which remains regulatory."

The virtual test bench that is being built with SimulationX is one of the major elements of DGA-EP’s digitalization initiative. Virtualization of both the test configuration and the engine (or other equipment) will make it possible to completely reproduce the test conditions and predict the performance of test equipment. In the longer term, DGA-EP plans to extend this work to progressively update the virtual test bench using data collected during actual physical testing, and ultimately to develop a Hybrid Twin™ of each testing installation, that will enable intelligent maintenance and support.