Meet ESI at the 50th International Paris Air Show

ESI Group, pioneer and world-leading solution provider in Virtual Prototyping for manufacturing industries, announces its participation at the 50th International Paris Air Show, Le Bourget. Located in the Hall 4, at booth B126, ESI will present both its new and established solutions for the aerospace industry, with a focus on Sheet Metal Forming, Composites Manufacturing and Performance evaluation, Seat Design and Pre-Certification and Immersive Visualization solutions that enable design for manufacturability and maintainability.

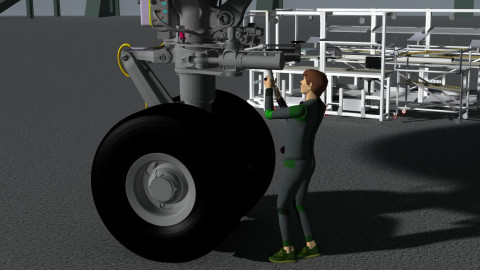

ESI's Virtual Reality Solution, IC.IDO, enables the evaluation of designs for maintainability, in an immersive 3D environment.

Held every two years, the Paris Air Show provides a great opportunity to meet aerospace leaders and to see the latest technological advances in the sector. This year, as a member of the aerospace cluster Pole ASTech Paris Région, ESI will be exhibiting among affiliates of the Paris Chamber of Commerce.

Benefiting from 40 years of R&D in material physics and from co-creation with global industry leaders and strategic partners that include Astrium and AVIC, ESI solutions are designed to help aerospace manufacturers meet global competition and global market demands. Compliance with new and upcoming regulations, including those aimed at reducing aircraft noise and greenhouse gas emissions, are amongst the challenges addressed.

Constant changes in regulations call for the introduction of new processes and new materials that must be evaluated quickly and reliably in order to control and guarantee the performance of future products. Virtual Prototyping enables the creation of virtual models that are as predictive as real prototypes. Successful application avoids errors, reduces the number of iteration loops needed to validate new designs, saves on prototyping costs, and shortens development times.

During the Paris Air Show , ESI’s Composites Simulation Suite will be showcased. This software suite enables the precise simulation of the manufacturing, assembly and future performance of composite components, taking into account coupling and chaining effects; replicating the building and testing of industrial components, part by part and subsystem by subsystem. This enables manufactures of important systems and components, such as aircraft leading edges, winglets, landing gear doors and seat structures, to assure high performance and manufacturability. In addition to exhibiting ESI’s existing solutions for composites engineering, ESI will share results of research projects aimed at extending the use of advanced composites to critical components in aircraft engines, to rotorcraft blades, to reflectors, and more.

ESI will also be presenting its new Virtual Seat Solution, a complete solution enabling the end-to-end Virtual Prototyping of seats. This solution helps seat designers innovate while addressing industrial imperatives for reducing weight, increasing living space and comfort, optimizing aircraft capacity and achieving safety certifications. Using ESI’s Virtual Seat Solution, involved teams work on a single core model of the seat to anticipate potential manufacturing and performance issues and manage conflicting seat design requirements earlier in the development process. The solution enables the design and pre-certification of safe, lightweight and comfortable seats at first try-out.

ESI’s immersive Virtual Reality solution, IC.IDO, is used to improve design for manufacturability and maintainability of new products; realizing significant savings over the lifetime of a program. Major aerospace companies and their suppliers use IC.IDO to perform collaborative and immersive design reviews, to evaluate and optimize assembly and disassembly sequences, to verify resources and tooling for both manufacture and maintenance, and to support documentation and workflow animation/ training. IC.IDO incorporates real time physics to detect contact and obstruction during assembly and maintenance procedures, and to enable instant evaluation of flexible components, such as pipes and cables.

Live demonstrations of ESI’s Virtual Reality solution, with special focus on design for manufacturability and maintainability will be made throughout the Paris Air Show. If you wish to pre-schedule such a demonstration, please contact Aurélien Gohier.

If you have any question about ESI’s attendance at the Paris Air Show, please contact Gaëlle Lecomte.

We look forward to seeing you in the Hall 4, at booth B126!