「ゼロプロトタイプ」:ExpliseatがESIのシミュレーションソフトウェアを使用して超軽量の航空機シートを開発

ESIはExpliseatの選択パートナーです。最初のモデルであるTiSeatE1は、完全にデジタルで開発された初の航空機用シートです。私たちは、「ゼロプロトタイプ」という意味で、製品設計から仮想プレ認証まで、正しい選択をするために完全にシミュレーションに依存してシートを開発しました。

Benjamin SaadaPresident, Expliseat

フランスのスタートアップ企業Expliseatはまだ10歳です。しかし、すでに他に類を見ない成功を収めています。航空宇宙産業が持続可能性の課題に直面している中、Expliseatの超軽量シートは航空会社が燃料費とCO2排出量の両方を削減するのを可能にしています。Expliseatのシートは1つあたり約6kg(従来のシートよりも平均で4kg軽量)、部品は50%少なく、それでいて乗客の安全性や快適さを損なうことなく、その秘訣は何でしょうか?次の目標を達成するためにどのような製品開発手法を使用しているのでしょうか?

デジタル化は彼らの最大の武器です

フランスのスタートアップ企業Expliseatはまだ10歳です。しかし、すでに他に類を見ない成功を収めています。航空宇宙産業が持続可能性の課題に直面している中、Expliseatの超軽量シートは航空会社が燃料費とCO2排出量の両方を削減するのを可能にしています。Expliseatのシートは1つあたり約6kg(従来のシートよりも平均で4kg軽量)、部品は50%少なく、それでいて乗客の安全性や快適さを損なうことなく、その秘訣は何でしょうか?次の目標を達成するためにどのような製品開発手法を使用しているのでしょうか?

シミュレーションのためにESIと提携

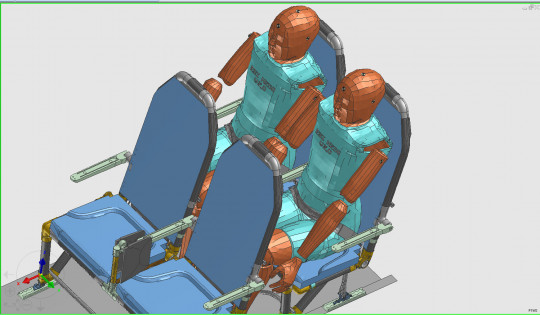

フランスのスタートアップ企業Expliseatは、航空機座席の開発において、シミュレーションソフトウェアを駆使して"ゼロプロトタイプ"のアプローチを採用しています。Expliseatの初のモデルであるTiSeatE1は、完全にデジタルで開発された初の航空機座席となりました。Expliseatは、製品設計からバーチャルプレ認証までの適切なタイミングで正しい選択をするために、シミュレーションに完全に依存しました。ヨーロッパ連合航空安全機関(EASA)による認証の最終段階まで、物理的なプロトタイプを1つも製造せず、その後の安全要件をすべて満たしていることを確認しました。この成功において、ESIは主要なパートナーの一つでした。Expliseatは、航空機産業における製品開発において、ESIのシミュレーションソリューションが戦略的な資産であることをすぐに理解しました。

Expliseatはシミュレーションの能力を向上させ続けています

10年間で、Expliseatの航空機座席モデルの13種類が短距離および中距離飛行に使用されるほとんどの航空機タイプに認定されました。過去3年間で、彼らは計算速度を300%向上させました。

クラウドの利用を最適化する

企業が始まった当初、彼らは10のワークステーションを持っていました。Expliseatは現在、Google Cloudサービスを使用しており、重いハードウェア投資を必要とせずに最大で2000コアを使用して最新のシミュレーションを実行できます。同社はクラウドでの高性能コンピューティング(HPC)機能を最適化し続けており、計算がはるかに高速に実行されるだけでなく、リソースとコストを最適化し、プログラムの開発コストを制御しています。

プラットフォーム開発

自動車産業で広く見られるクロスプラットフォーム開発は、複数の製品バリエーションで同じパーツを使用することに基づいています。類似した基盤で作業しながらも、異なるデザインや機能を提供することで、メーカーはカスタマイズのニーズに応えながら、開発コストを最小限に抑えています。サーダ氏は「プラットフォーム開発は航空宇宙産業ではまだ新しい概念です。ESIの自動車業界の顧客がシミュレーションで何ができるかを見て、確立されたシミュレーションプロセスを複製することがExpliseatにとって戦略的な資産であることが理解できました。」

TiSeatE2プログラムは、Expliseatにおけるクロスプラットフォーム開発の成功を具現化しています。このモデルは現在、4種類の異なる航空機タイプに展開されています。部品の80%がすべての4つのバリエーションで共通です。サーダ氏は「これを今後さらに高めていきたいと考えています。自動車産業では最大90%の類似性が達成可能だとわかっています」と述べています。

安全第一

航空機の座席は、搭乗中の乗客の主要な安全装置です。Expliseatが航空機シートの軽量化にカーボンファイバーコンポジットを使用することを考えたとき、動的試験が非常に困難になることを理解していました。サーダ氏は「Expliseatの世界的なコンポジット技術の専門知識と組み合わせて、ESIのシミュレーションは、望ましい安全要件を達成するための戦略的なツールでした」とコメントしています。

TiSeat E2 seat model on Porter Airlines Dash 8-400 aircraft. Image courtesy of Expliseat.

マニュファクチャリング4.0

「新しい製造プロセスによりさらなる軽量化が可能だと確信していますが、これには一定数の製品部品を再設計または再最適化する必要があります。したがって、ESIの製造 4.0 ソリューションを活用することが次のステップです。より大きな質量最適化を実現し、リードタイムを短縮し、製品開発リスクを最小限に抑え、保守的な設計決定を回避することを目指しています。シミュレーションに頼ることで、必要な箇所で部品の堅牢性を正確に高めながら、余裕のある箇所ではそれを減少させることで、さらなるシートの軽量化を実現できます」とサアダ氏は説明します。 Expliseatにとって、ESIの製造プロセスシミュレーションソリューションは新しいモデルの生産開始にも役立ちます。「誰もが、それが起こるときにツールが役立たないことを知りたくありません」と彼は微笑みます。

About Expliseat

Expliseatは、世界で最も軽量な航空機シート、TiSeatの製造元です。高性能な素材と革新的なソリューションを組み合わせて、輸送効率を向上させています。Expliseat製のシートは、最新の航空航空適合性要件に準拠して認定されており、これにはHead Injury Criteria(HIC)テストも含まれます。TiSeatsは、Airbus A320、Boeing 737、ATR、De Havilland Dash 8、またはDassault Falcon Jetsなど、複数の航空機プラットフォームで利用可能です。2020年には、TiSeatが世界中の15以上の航空会社で運航され、収益や環境への認識された利点が高いフィードバックを得ています。航空機での大量の重量削減により、燃料消費量を削減し、それによりCO2排出量を大幅に削減することが可能です。

詳細については、https://expliseat.com/ をご覧ください。