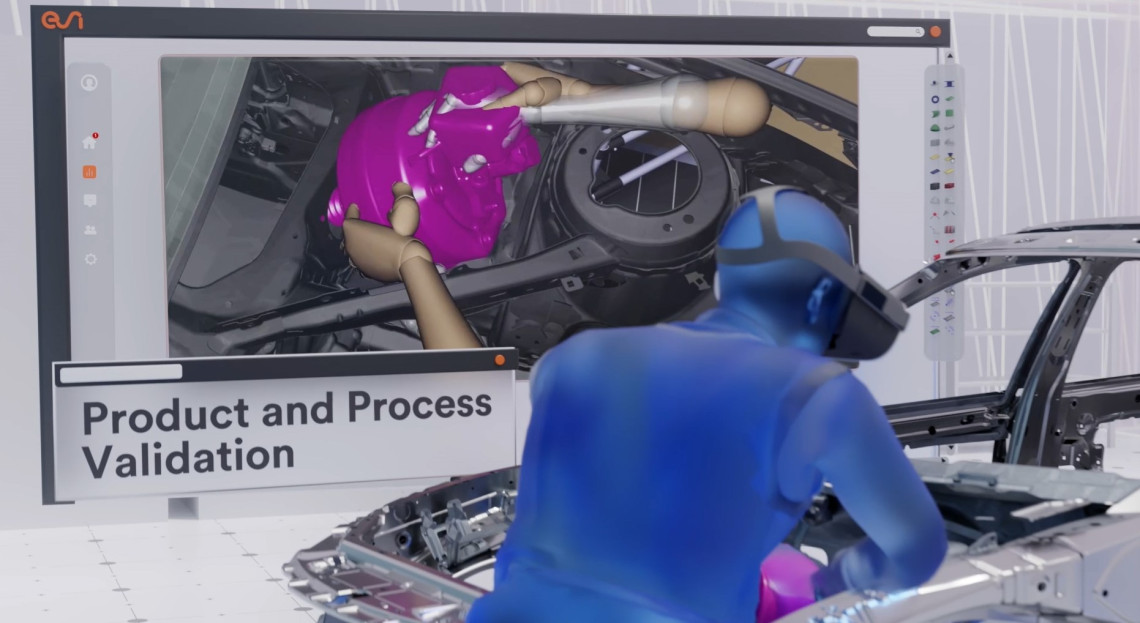

The Role of XR and VR in Product Integration and Process Validation

A Q & A Discussion

As products and manufacturing processes become increasingly complex, companies are turning to immersive technologies like eXtended Reality (XR) and Virtual Reality (VR) to streamline product integration and process validation.

Traditionally, businesses relied on 3D CAD models reviewed on flat displays and physical prototypes to assess designs and test feasibility of human-machine interactions common in manufacturing and maintenance of new products. While these methods have been effective, they come with limitations—high costs, long lead times, and constraints on collaboration.

XR and VR offer a new way forward, enabling teams to interact with digital models in fully immersive experiences, reducing the reliance on costly physical mock-ups and accelerating decision-making.

However, widespread adoption presents challenges, from IT infrastructure hurdles to shifts in organizational mindset. In this discussion, we explore the evolution of XR and VR in product development, the barriers to adoption, and the steps companies can take to integrate these technologies effectively.

How were product integration and process validation handled before the adoption of XR and VR?

Without XR and VR as part of the product development and validation process, companies rely heavily on two primary methods.

First, teams would assess designs using “flat” on-screen representations of 3D CAD models. This meant sitting together around large screen projections of these models or perhaps online using remote screen sharing views. In this mode participants are limited to a single shared perspective controlled by a CAD operator or meeting moderator. While still a crucial part of the process today, it presents challenges in representing human-workflows for feasibility when working with increasingly complex products within an on-screen environment.

Second, physical prototypes or mock-ups previously played a vital role in product design decision-making and dynamic process validation. These prototypes had been necessary for testing, building confidence in manufacturing feasibility, and ensuring serviceability. However, their use has been reduced due to high costs and time-consuming fabrication. As a result, any physical mock-ups are only built later in the product lifecycle, when designs are assumed to be more stable and proven. Making late-stage design changes based on first-hand experiences with physical prototypes is costly and inefficient, often too late to make significant improvements.

The introduction of XR and VR shifts this landscape dramatically, offering firsthand experiences with people interacting with digitally modelled products in the context of general assembly, maintenance, and operation. Immersive experiences powered by solutions, like IC.IDO from Keysight Design Engineering Software, offer more flexible, scalable, and cost-effective validation methods compared to the traditional on-screen viewing or physical mock-up approaches.

When we experience assembly or service processes in XR/VR, we essentially become part of the simulation, right?

Yes- once someone puts on VR glasses or an XR headset to participate in virtual build or virtual maintenance experience, they become an active and unique input in the validation process. Instead of just observing a digital model, they interact with it, personally participate in the build, and can provide real-time feedback and insights. Giving plant workers a chance to apply their production expertise to inform tooling and standard decisions is common today, but letting them make those suggestions without investing in tooling fabrication or waiting for installation is groundbreaking.

This shift away from reliance on physical prototypes toward virtual experiences allows for more effective testing and decision-making earlier in the development timeline. The ability to integrate human interaction into build or maintenance simulations significantly enhances the reliability of process validation and method planning.

Where are we now in terms of replacing physical mock-ups with virtual or extended reality models?

Most organizations had already eliminated, or steeply reduced, their physical prototyping investments and suffered from an increase in late identification of issues as a result. Many teams are still in an exploratory phase, evaluating how to apply the full range of XR’s capabilities to their product development and process validation methods. While XR and VR technology has proven to be highly valuable, full-scale adoption remains a challenge due to several barriers.

One major obstacle is technological—such as issues with CAD data flows that complicate advanced virtual validations. Another challenge is human-related, including the need for upskilling and developing VR competency among teams.

New product development (NPD) processes need to be restructured to allow for timely sharing of relevant data with different parties within the enterprise. Greater investment in process engineering effort needs to be made early. The availability and transfer of CAD data and process plans, between product development teams and manufacturing or service process planning needs to be optimized to support virtual validations effectively. While some teams have successfully adopted this approach and are using virtual prototypes to identify and correct design flaws early, many organizations still need to refine their workflows to maximize VR’s potential.

A key step in this transition is the willingness to prioritize additional virtual process validations and investing in new virtual work, instead of leaving available time for waiting until physical parts and production tooling is available. Once teams take that leap, investing earlier to avoid late changes, business processes can evolve, making virtual validation a more integral part of the development cycle.

Beyond organizational barriers like data sharing, what are the main technological hurdles that need to be overcome for widespread XR/VR adoption?

Several challenges remain, despite the technology being available.

One significant issue is IT infrastructure. Just as companies once struggled with integrating personal mobile devices into corporate networks, they now face similar challenges with VR headsets—many of which run on Android-based systems. These devices need to be securely registered, granted permissions, and managed effectively.

Another critical factor is network capability. Running collaborative virtual simulations requires high-speed, low-latency connections. Existing Wi-Fi networks are often insufficient for handling multiple simultaneous XR users, making private 5G networks a potential solution. However, these networks, along with the necessary hardware (such as 5G-compatible headsets), are still in the early stages of development and deployment.

While progress is being made in these areas, widespread adoption will require continued advancements in IT management, network infrastructure, and seamless data streaming capabilities.

What immediate steps should enterprises take to continue making progress in replacing physical prototypes with virtual ones?

The first step is measurement. Organizations should evaluate their current VR adoption levels using tools like a maturity model, which assesses technological, organizational, and process-related variables. This helps identify what is working and what needs improvement.

Second, there needs to be a mindset shift. Companies must recognize that integrating VR is not an overnight process. Success requires exploration—not just of the technology itself but also with new workflows and methodologies.

Unfortunately, many enterprises had already eliminated investment in physical mock-ups and lost the learning that comes with it. Eliminating the physical construction of prototypes and mock-ups does not eliminate the value derived from those physical experiences. At a higher level, management must be willing to invest in new methodologies as they move away from early-stage physical prototypes and prioritize expanding virtual validations. While this won’t happen instantly, some NPD projects can begin taking this step now. Challenging teams to embrace this transition is key to making meaningful progress.

Finally, organizations should ensure that VR adoption is driven by clear business value. Rather than expecting a one-size-fits-all solution, companies should identify the specific solutions and applications where each provides the greatest return on investment. The XR/VR tools that aid organizational development, marketing and training, are very different than XR/VR solutions used for manufacturing planning or product development.

Beyond the technology itself, how should enterprises integrate XR/VR effectively into their business operations?

For XR to succeed, it cannot simply be treated as a standalone technology for technology’s sake. It needs to be fully integrated into business functions, with proper operating models, customer engagement strategies, and clear use cases aligned with real business challenges. It needs to be recognized as a “means to an end” and not the deliverable in itself—OEMs are not profiting on the XR/VR deliverables, but rather what XR/VR allows them to deliver in terms of their product quality and cost.

Additionally, scaling XR across an organization requires strong collaboration with IT teams. Instead of being confined to small, specialized VR teams, the technology should be accessible and easy to use across departments. Lest XR/VR become a “monument” or bottle neck in their lean journey, democratizing access, standardizing support and simplifying the user experience—making it as easy as pressing a “big green button”—will be crucial to widespread adoption.

A key indicator of success is when users focus on their work rather than the technology itself. If employees spend more time talking about the VR system than using it to solve real business problems, then something needs to change.

What are the next steps to ensure continued progress in XR/VR adoption and integration?

In the short term, companies need to focus on foundational improvements—ensuring IT can register and manage devices, set up robust network infrastructure, and eliminate inefficiencies in CAD data workflows. These are crucial but often resource-intensive steps.

Looking ahead, the evolution of XR will make it even more integral to daily operations. Currently, headsets are bulky and require significant computing power. However, as technology advances, we can expect lighter, more user-friendly devices that seamlessly integrate into work environments.

Another key shift will be in how XR is used—not just for efficiency but also for creativity. For example, styling teams are already using 3D sketching tools in XR to generate more ideas in less time. Over time, XR will transform from a tool for optimizing existing workflows to one that enables entirely new ways of working.

Ultimately, organizations must be prepared for this transformation. Many traditional engineering milestones were based on physical prototyping because that was the only way to make certain decisions. That deferred many critical decisions to very late or forced decisions based on suboptimal best guess animations or simulations. With XR, those decisions can now be made earlier in the process in true-to-life virtual experiences, with greater confidence than previous on-screen “puppet shows”. Companies must adapt their structures, decision-making processes, and overall mindset to fully leverage this potential.

The businesses that embrace this shift will be the ones that gain the most value from XR—reducing risks, cutting costs, and unlocking new opportunities for innovation.

Is IC.IDO the answer?

The integration of XR and VR into product development and process validation has significantly changed how companies approach design, testing, and collaboration. While these technologies offer immense potential—reducing reliance on physical prototypes, improving efficiency, and enabling more informed decision-making—there are still hurdles to overcome. However, as businesses continue to refine their workflows and adopt these tools at scale, the benefits will only grow. By embracing virtual prototyping and leveraging immersive simulations, teams can unlock new levels of innovation and efficiency.

For organizations looking to navigate these changes seamlessly, IC.IDO provides the solution to overcome these adoption barriers, optimize workflows, and maximize the value of VR.

IC.IDO is ESI's (part of Keysight Technologies) Virtual Reality software platform that is revolutionizing product development and process optimization by enabling collaborative virtual workflows.

By immersing teams in high-fidelity, full-scale virtual mock-ups, IC.IDO allows enterprises to experience future products, evaluate integration, and optimize human-centric processes long before physical production environments are available.

This proactive approach helps identify potential issues early in the development process, when design changes can still be made without incurring dramatic costs or delays, ensuring more efficient and effective product designs.

To find out more about what IC.IDO can do for your organization, check out the dedicated IC.IDO webpage or get in touch.

Katharine Edmonds is a Content Marketing Specialist at ESI Group, and has spent the past 9 years working in marketing and communications for SaaS providers in the engineering and manufacturing industries. Katharine leans on her knowledge and experience of CAD, PLM and eXtended Reality (XR) technologies to create engaging and informative content that champions the benefits of virtual prototyping, and bridges the gap between complex technical subjects and a broader audience.