From Launch to Landing: Solving Space Industry Design Challenges with Virtual Reality

Reducing Risk and Cost in Space Missions Through Immersive Validation

Breakthroughs in launch vehicle and booster return introduce novel challenges to the space industry. Previous generations of launch boosters and vehicles designs, and fuel/propulsion systems limited them to life as single-use assets. Today, new rocket engines and boosters that can safely and predictably return for safe terrestrial landing or capture are game changers; introducing greatly increased launch frequency and a need for sustainable remanufacturing plans for launch boosters and vehicles.

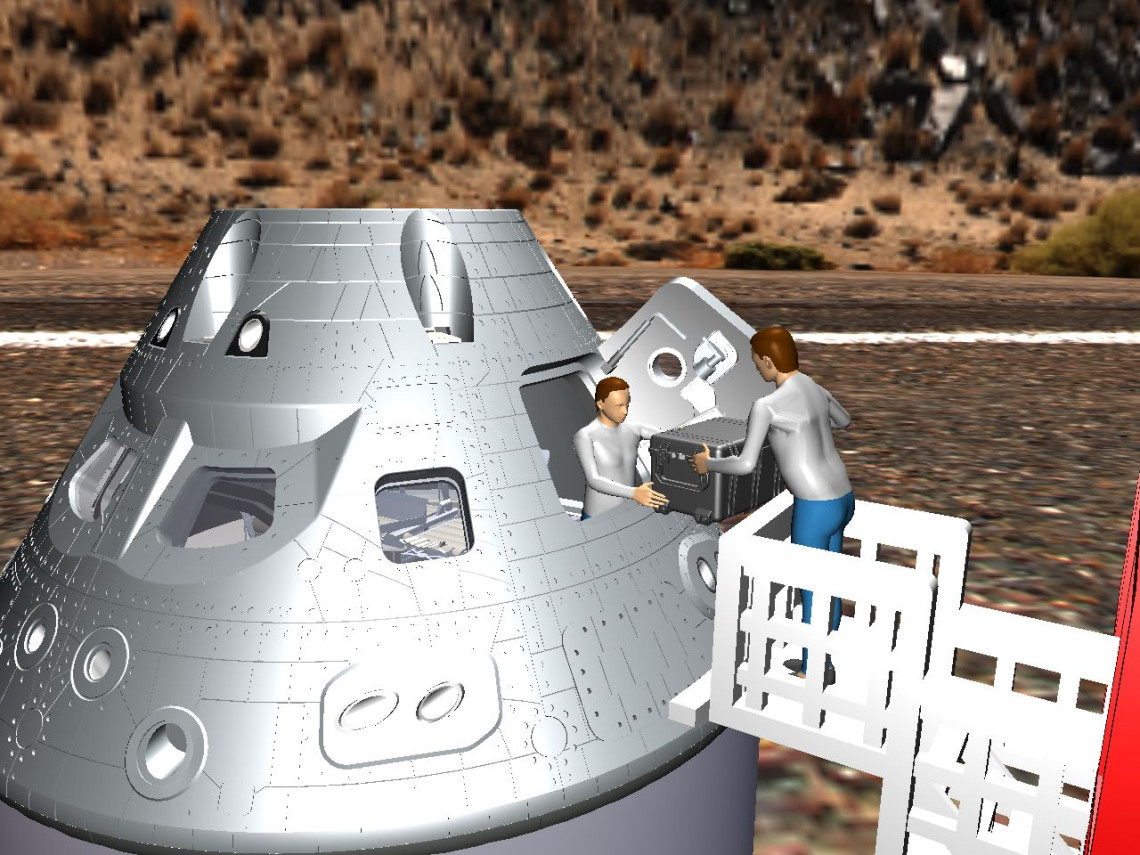

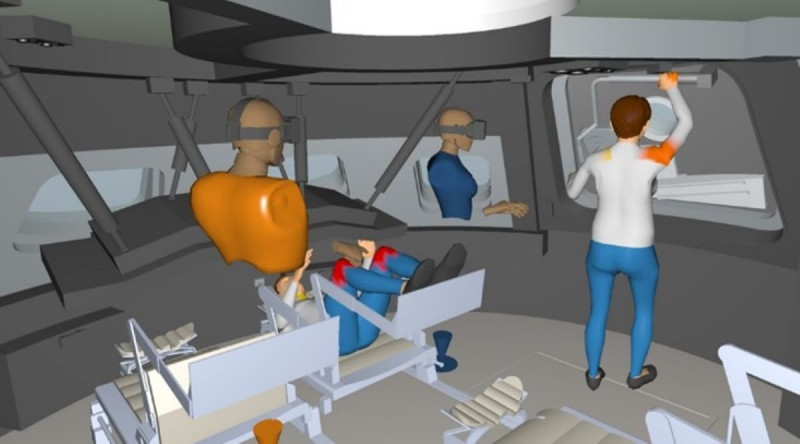

Additionally, ambitions for more crewed missions, and re-usable crew capsules-whether for docking with space stations or future non-terrestrial landings- re-ignite interest in designing safe, practical and comfortable operator packaging. These human-centric design challenges haven’t been addressed in depth since the Space Shuttle era of space exploration and near-earth orbital travel.

Innovation often leads to challenges with commissioning the manufacture, operation, care and maintenance of first-of-a-kind or few-of-a-kind assets. During the engineering and development of a unique asset like a crewed space capsule, integrated product teams (IPT) often are left to wait for physical validation of complex packaging and integration design decisions. When every component is “mission-critical”, leaving validation of visibility, reachability, accessibility and replaceability of a unique multi-billion Euro or Dollar asset can’t wait until mission specialists are constructing life-saving equipment.

With Virtual and eXtended reality product integration evaluations and validation of Human-Centric Procedures like operation, maintenance, or assembly, space exploration enterprises can experience the spaceships of tomorrow, today.

SpaceX Dragon v2 (Crew) . Image courtesy of Wikimedia

Practical Use Cases for VR in the Space Industry

Image courtesy of SpaceX.

Pre-Flight Certification and Commissioning

Before anyone takes a ride atop a rocket, numerous tests are conducted on the individual engines, boosters, and flight control systems. Recently introduced as the benchmark for space exploration, static testing, limited autonomous flight tests, and full launch autonomous flights and retrieval have created many opportunities for experiencing and evaluating procedures for reclaiming, re-using, and remanufacturing rockets.

However, physical experiences with actual test vehicles are still a risky proposition, putting workers in potential harms way while handling unique few-of-a-kind assets necessary for testing and commissioning. It’s also perhaps not the most cost-effective means for “learning-as-we-go”.

With reliable Virtual and eXtended reality technologies, engineers, maintenance technicians, and rocket scientists alike can experience participating in the removal and replacement of key components. These immersive tools allow teams to validate accessibility with tools, and the reconnection of critical componentry while minimizing risk to the rocket engines or themselves and co-workers. The ability to evaluate proposed packaging and integration of novel propulsion systems weeks, months, or even years before the availability of physical examples of real-world products. Thus making “time travel” a key enabler to space travel.

Operation and Maintenance Process Planning

There are no pareto charts with the top 10 things to repair or replace when you have a first-of-a-kind product such as a crewed space vehicle like the Dragon, Starliner, new Shepard, Starship, Orion, Artemis, and others. Few of these craft have had sufficient numbers of crewed missions to have encountered all the necessary field expedient service requirements, let alone be able to identify which misson critical components are most likely to need replacment or refurbishment as part of planned maintenance. Until now, the practice has been to completely rebuild, or to just use a new vessel. Determining which components might need to be accessed for replacement or inspection is still only part of the process of determining the minimally invasive method to access or conduct expedient service.

Decisions made very early on in the design and commissioning process can very easily become life-and-death decisions; None should be taken lightly nor without taking every measure possible to identify risks and mitigate or eliminate through design. However, building physical mock-ups or having workers conduct evaluations on the actual space craft or launch vehicle can introduce opportunities to overlook potential issues for logistics or economic reasons. No flight mission specialist would want to have on their conscience the knowledge that something they did not inspect or evaluate thoroughly leads to disaster.

With solutions like IC.IDO engineers have the freedom to work directly with CAD flight-intent geometry models without risking design oversights or “green washing” simply by making the data more loadable into a VR Solution. No one wants to know an avoidable incident was a result of data optimization or polygon decimation.

With Virtual Reality integration reviews, Integrated Product Teams (IPT) can run near infinite variations of product layout and topology with only the cost of CAD data. Maintenance and service crews can try as many alternative procedures for removal and replacement of components as they can think of-even those that engineering did not anticipate would be a “top ten issue”- without risk of error by oversight.

Installation and Preparation for Launch

When dealing with critical assets-such as the first crewed vessel planning to travel between earth and the moon since the mid-20th century, or perhaps a mission to Mars- nothing is trivial. Just prepping the capsule for shipment from construction site to planned launch site is a logistic and engineering challenge that should be fully validated prior to risking the only spaceship an enterprise or nation might have. Maintaining the safety of crew, technicians, and spacecraft by maximizing the experience gained through physical interactions between the product and operators is a paramount consideration.

With true-to-life physical behavior and interactions in real-time simulated experiences, stakeholders can safely conduct load-in and load-out of the vessel, and prepare for shipment numerous times, all while maintaining the flexibility to assess alternative geometry if evaluations lead to late engineering and design changes. They can conduct procedures as need arises and record those processes for communication to engineers and method planners upstream of them in the design process, or technicians downstream responsible for their aspects of the mission.

Field Expedient Repair, Service, or Modification of a One-of-a-kind Product

Have you read the book “The Martian” by Andy Weir, or watched the movie starring Matt Damon? If not, stop reading now, SPOILERS will follow.

You have been warned.

In the movie, to rescue astronaut Mark Watney from MARS, the teams at NASA and JPL have idea that if he can modify the MAV (Mars Ascent Vehicle) to make it lighter he could safely reach a higher orbit and facilitate an eventual rescue by his team as they make a high-altitude transit of the red planet (excellent reading or watching). In a key scene in the movie they depict mission commanders and scientists discussing over skype how to remove massive content from the capsule to reach the target weight. As they explain the math they use “paper doll” scale mock-ups to represent the removal of key components.

If this were real-life, one would hope that the teams had access to a 1:1 physical mock-up or duplicate of the real thing- but maybe not the real lander for the next planned mission since these modifications would undoubtedly ruin the MAV for intended use in the future!

But with IC.IDO and the existing CAD geometry, experts could safely and repeatedly take it apart and validate that the accessibility exists to remove the excess mass and develop and optimize the procedures to be completed by a single operator in a difficult environment.

Maybe in VR we still can’t completely accommodate simulation of reduced gravity of Mars vs. Earth, but we could certainly put someone in an identical suit, put them in VR, and have them perform the procedures in Virtual or Mixed reality to safely tryout the disassembly procedures and optimize them before sending the work-instructions to Mars.

Save Mark Watney and learn more about IC.IDO!

Eric Kam is the Marketing and Alliances Director for ESI Group’s Manufacturing Business Channel, supporting their Immersive Experience (VR/AR/MR/xR) Solutions and Virtual Manufacturing Suite. He is an outspoken advocate for the ongoing transformation in Computer Aided Design, Finite Element Analysis, and Computer Aided Engineering. He has spent the bulk of the last 25 years promoting the democratization of previously “analyst-driven” technologies to bring the benefits of Virtual Engineering tools to the engineering and manufacturing practitioners themselves.