Worldwide

10am CET

1h

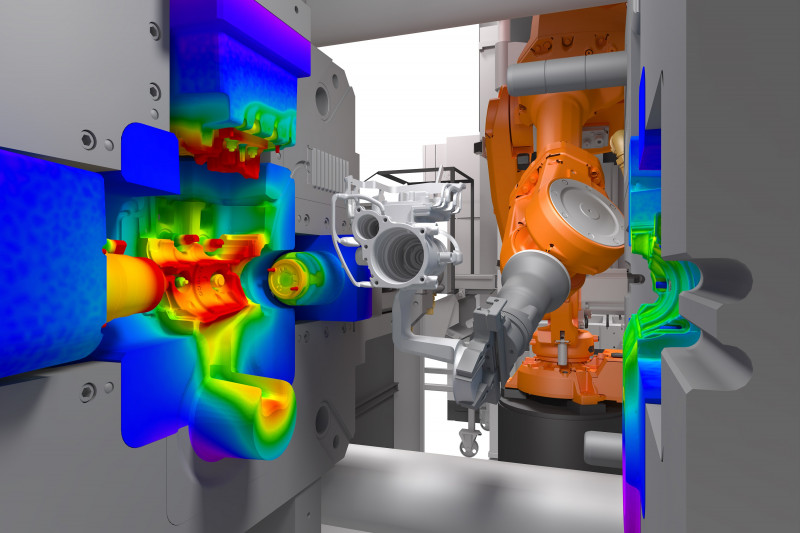

Simulation facilitates tool design and predicts and quantifies defects during the development phase for new parts. The objective is to reduce the number of physical attempts in order to achieve "first-time-right" parts.

Simulation allows cast part manufacturers to test their casting processes completely virtually early in the process development cycle. Accurate prediction and quantification of defects and process design are imperative to ‘get it right’ during production trials. With casting simulation, you can reduce the scrap rate while meeting your deadlines and minimizing the costs associated with last-minute modifications.

Watch our On-Demand webinar where you will discover how digital simulation supports you throughout your products' development and manufacturing phase.

Key Topics & Registration

- Work hand-in-hand with customers providing part design to check for castability issues as early as possible in the process, to accelerate the start of production

- Deliver accurate quotes, with precise material cost estimates to safeguard your margins

- Predict, analyze, measure, and quantify the most common casting defects to reduce your scrap rates and expensive reworks

- Applications: Optimize residual stress & distortion, Analyze microstructure & heat treatment, Use advanced porosity model, Study grain structure

- Optimize Casting Process, Model Heat Treatment, Analyze Performance of the Casted Part