AddUp and ESI Group intensify their collaboration by presenting “Distortion Simulation AddOn” at Formnext 2018

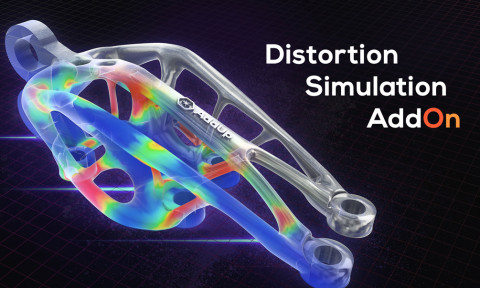

AddUp, a leader in industrial solutions for additive manufacturing, and ESI Group, a leader and pioneer of virtual prototyping solutions based on material physics, have announced the forthcoming availability of Distortion Simulation AddOn. This module will enhance the range of functionalities of the AddUp ManagerTM software for the definition and production tracking of parts in additive manufacturing.

Founding members of the SOFIA project (Solution pour la Fabrication Industrielle Additive métallique – Industrial Metal Additive Manufacturing Solution), initiated in 2016 and sponsored by Bpifrance, AddUp and ESI Group have shared a common vision of metal additive manufacturing ever since their first meeting. At a time when the industrialization of additive manufacturing has become reality, simulation based on material physics, which ensures an in-depth understanding of material processes and behavior, is one of the key components to improving the competitiveness of the additive manufacturing process.

Controlling manufacturing processes

The optimization of process parameters is a crucial stage in the additive manufacturing process and a driver of competitive differentiation. Manufacturers, according to their specific applications, must be able to focus available machine times either on production or on process optimization.

Traditionally, production validation has meant primarily producing parts, then assessing their conformity. Introducing a simulation tool, all too often limited expert users, required multiple feedback loops between different functions, creating discontinuity over the digital chain.

By integrating simulation directly in the preparatory stages of additive manufacturing, Distortion Simulation AddOn brings continuity to the production process. The AddUp Manager user interface, intuitive and stable, offers the ideal working environment for defining simulation parameters, particularly for staff who are not experts in this field.

“With this simulation technology we can help our customers improve their operational efficiencies and responsiveness, by significantly increasing the number of first time right parts” explains Vincent Ferreiro, CEO, AddUp. “Thanks to its accessibility, Distortion Simulation AddOn will appeal to a wide range of users, requiring only a very short learning curve. This tool will help them maximize the potential of our FormUp machines.”

Combined expertise has enabled AddUp and ESI Group to generate results that really matter to industry, taking all production parameters into consideration. The process is based on a succession of simple, guided steps. The level of detail is configurable according to customers’ needs: from optimizing industrial production to verifying small series.

Simulation results allow physical characteristics of parts, displacements, strains and residual stresses, to be correlated with the feasibility criteria calculated upstream of production. This allows risks of production downtimes due to collisions of the roller or scraper to be anticipated. At the end of the process, a modified geometry is generated. Based on predicted deformations due to the process and exportable to STL format, this helps ensure geometrically compliant production.

A partnership geared to industrial competitiveness

“The complementary nature of our teams and our fields of expertise, backed up by our collaboration in the SOFIA project, has enabled us to develop an industrial solution that delivers performance, predictability and competitiveness while continuing to implement innovative production methods such as additive manufacturing,” comments Vincent Chaillou, COO, ESI Group.

Distortion Simulation AddOn is the first milestone in the collaboration of these two leaders of the metal industry, who have gained an undisputed mastery of their respective fields. Promoting the competitiveness of the additive manufacturing industry, this first joint project confirms and reinforces the leading roles of AddUp and ESI Group.

Based on complementary expertise, AddUp and ESI Group have thus firmly established their cooperation, sharing know-how and building their respective competitive strengths for the future. AddUp, with its highly open and flexible production systems, is further improving its mastery of industrial processes and the power of its software packages. ESI Group, with its background in material physics, reinforce simulation of machine behavior in metal additive manufacturing of the highest level.

Distortion Simulation AddOn will be available in the spring of 2019.

The collaboration will be presented on AddUp booth (3.0 C21) Wednesday November 14th at 1:30pm.

AddUp est née le 1er avril 2016 suite à la décision des deux groupes industriels Fives et Michelin de créer un acteur majeur de l’impression 3D métallique. Cette co‐entreprise a pour ambition de faire bénéficier ses clients de son expérience et de son savoir‐faire unique en développant et commercialisant à l’échelle mondiale, des machines et des ateliers de production industriels utilisant la technologie de fabrication additive métallique, communément appelée impression 3D Métal. L’offre AddUp intègre la technologie de fusion sur lit de poudre (LBM : Laser Beam Melting) ainsi que la technologie de projection de poudre métallique par laser (DED : Directed Energy Deposition) depuis l’acquisition de BeAM en juin 2018. AddUp propose également des offres de services, consulting et de formations pour accompagner ses clients dans l’adoption de la technologie. Grâce à la récente prise de participation majoritaire dans la société française Poly-Shape, AddUp peut dorénavant proposer à ses clients un accès unique à une plateforme multi-fournisseurs, multi-technologies, multi-matériaux, multi-applications pour répondre à tous les projets de production de pièces. AddUp, avec un siège à Clermont‐Ferrand et des filiales aux Etats‐Unis et à Singapour, compte actuellement plus de 300 salariés.