Eberhard Haug, Co-founder of ESI Group, speaks about the origins of PAM-CRASH, ESI’s first flagship software, and recount tales of ESI’s first car crash simulation for Volkswagen, in 1985

“PAM-CRASH, ESI’s first packaged software, originated from research aimed at simulating aerospace and nuclear applications. At a meeting organized by VDI (Verein Deutscher Ingenieure) in Stuttgart on May 30, 1978, we presented the simulation of the accidental crash of a military fighter plane into a nuclear power plant. German automobile manufacturers became alerted to the possibility of using this technology for the simulation of destructive car crash tests.

Eberhard Haug, in 1976 & in 2006

In the following years, German car makers produced more complex crash simulation studies, simulating the crash behavior of individual car body components, component assemblies, and quarters or halves of the car body-in-white (BIW). These experiments culminated in a joint project by the Forschungsgemeinschaft Automobil-Technik (FAT), a conglomerate of all seven German car makers (Audi, BMW, Ford, Mercedes-Benz, Opel, Porsche, and Volkswagen), which tested the applicability of two emerging commercial crash simulation codes. One of them later became ESI’s PAM-CRASH, a solution that has since evolved to become ESI’s Virtual Performance Solution (VPS), covering crash, impact and occupant safety, linear & nonlinear statics & dynamics, strength & thermal, NVH (noise, vibration and harshness) as well as interior acoustics and seat prototyping.

By 1986, we achieved the objective of recreating a frontal impact of a full passenger car structure, running the simulation on a computer overnight. Now that turn-around time between two consecutive computer runs did not exceed one day, engineers were able to make efficient and progressive improvements of the crash behavior of the analyzed car body structure.

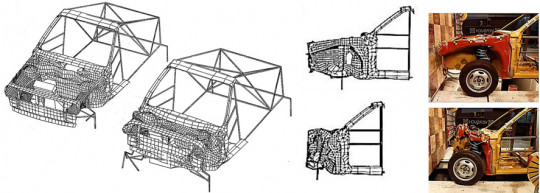

At the time of the first Volkswagen Polo car crash simulation, in 1986, the car meshing was only composed of 5555 shells, 106 beams and 5100 nodes. Today, car manufacturers work with numbers of elements exceeding millions of elements.”

Volkswagen Polo crash simulation (1985); side views of simulation (1985) & real crash tests (1984)

Today...

At Volkswagen, we have been using Virtual Performance Solution for several years now, and recently, in collaboration with ESI, we improved the simulation of a head impact on a windscreen. Using a new non-local failure criterion for laminated glass in Virtual Performance Solution 2011, we could calibrate one criterion and evaluate its accuracy by comparing with several experimental results. We confirm its use at an industrial level as the criterion works very well for multiple load cases.

Dr. Helge Liebertz, Project Engineer, Volkswagen AG (Germany)