Virtual Manufacturing of Auto/Aero Components using Composites

India

11:00 AM (IST)

1

Virtual manufacturing of Composite and Plastic components in Aero and Automotive application is the next big thing as there is increased dependency for light weight composite component with structural durability in both Aero and Auto sectors. Auto and Aero makers strive to reach their goals without sacrificing strength, stiffness, or performance of the manufactured components. The objective is to thrive OE’s and Suppliers towards light weighting technology thereby making use of composites and plastics helping them to maintain the cost effectiveness along with the compatibility for mass production. Virtual manufacturing plays a pivotal role to understand pain points , manufacturability and design changes if required through simulation thereby reducing the scrap rate and labor time.

Key Topics:

1. What ESI PAM- Composite has to offer

- Thermoforming application

- RTM Application

- Curing and Distortion Analysis

- Sheet molding compound

2. Thermoforming Case Studies

- Flap Rib rubber pad forming

- Wrinkle prediction

- Wing box Thermoforming

3. ARRK Case Study

- Reduction of weight by replacing Aluminium components with composite for gearbox housing

4. SMC Development

- What's new in Sheet molding compound ?

- What ESI has to offer in SMC

Join us as we discuss the Virtual manufacturing of Composites, a new aid for demanding future in Auto and Aero sectors and what ESI Software has to offer in order to reduce weight and time to get it right for the very first time during manufacturing process.

Register for Live Composite Workshop

18th May 2021, 11:30 AM

Join Live workshop on RTM Process

In this workshop, we will be covering the following hands-on DEMO in the RTM process

- Simple Geometry CAD example and Finite mesh creation

- 2D mesh corrections and quick Auto corrections

- Resin and Reinforcement Boundary condition definition

- Vents and Resin inlet definition for optimum flow

- Running the simulation and Evaluating the results

Register for Live Composite SMC Workshop

4th June 2021, 11:30 AM

Join Live workshop on SMC Process

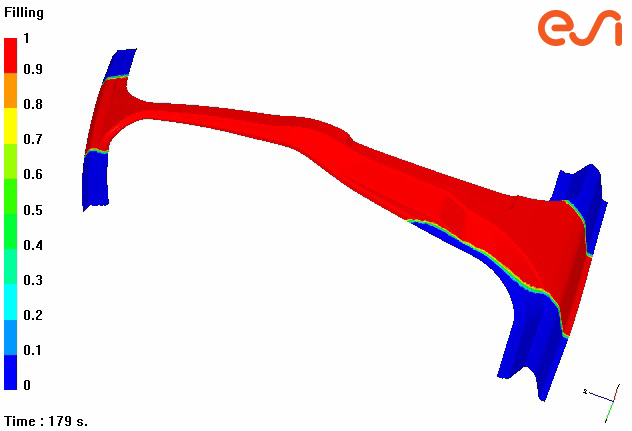

Sheet Molding Compound (SMC) is a proven technology for manufacturing non-structural parts in large production series. It is already widely used to achieve multi-purpose lightweight engineering at lower cost. However, for its usage on structural components, engineers need to estimate local material properties induced by manufacturing in advance, at design stage. Hence making SMC simulation possible at early stage become a must to understand and control the fiber reactions during Manufacturing and thus make proper design adjustments and validation.

ESI PAM-COMPOSITE has integrated the SMC module in its industry proven composites simulation solution. In a single simulation, the complete SMC process is predicted accurately, starting from the forming of the charge until its compression. Manufacturing results can then be transferred in a seamless way to dynamic or static structural analysis.

Agenda

1.ESI PAM-COMPOSITES introduction

2.What is SMC?

3.What does SMC simulation mean?

4.Area of applications

5.Live demo

6.Q&A session