As industries place sustainability at the top of their agenda, electrified machines are key to meeting ambitious zero-emission goals – this is more than ever relevant in the Heavy Machinery market. With profitability uncertain, reducing cost and time to market remains a priority. OEMs and Tier 1s count on Virtual Prototyping to get their sustainability practices right and simultaneously improve R&D efficiency on their “Mission Zero” journey - ensuring they meet customer’s operations targets and performance expectations.

How so? Witness how heavy machinery and off-highway vehicle makers ensure they are making the right decisions at every step of the process to achieve their goals. Ultimately extending the operational life of their machines from the development stages - without producing many physical prototypes. Getting development practices right virtually is the only way forward towards acting in a truly sustainable way.

ESI LIVE and its Heavy industry session will share concrete best practices for establishing integrated and automated digital workflows to efficiently design, test, operate and maintain machinery meeting the highest quality standards and lifetime performance for the most challenging usage conditions.

Highlights include :

- Insight from industry leaders on how they embrace digital transformation to achieve R&D excellence while maximizing profitability - reducing cost and time to market simultaneously.

- Expert panel discussions with peers in the Heavy industry on translating a Zero-Emission Strategy into Reliable Technical Specifications

- Industry presentations sharing best practices and innovative solutions for Virtual Proving Ground, Design for Operations, Manufacturing & Maintenance, and Life Time Product Performance

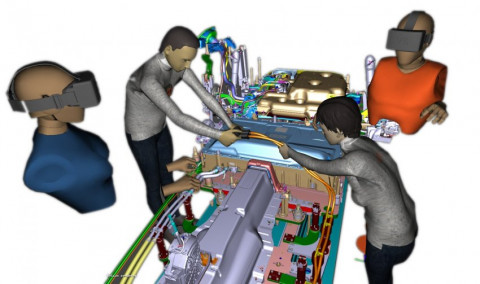

- Live demonstration on human-centric product and process validation to predict and mitigate risk, to assure on-time delivery, optimal performance and a safe work environment with advanced Virtual Reality

Speakers & Panelists

Agenda

2:00 - 2:45pm - Opening & Thought Leadership Panel

2:45 - 3:00pm - Digital Networking & Live VR Demo

3:00pm Start of the Heavy Machinery Track

3:00 - 3:20pm - Downsizing of combustion Engines for more sustainability - Rajesh Malik, CNH Industrial

3:20 - 3:40pm - The joint research project “Bauen 4.0” – Towards more sustainability and productivity

on construction sites - Prof. Dr.-Ing. Jürgen Weber, TU Dresden

3:40 - 4:00pm - A Human Centric approach to Manufacturing Process Validation through Virtual Reality - Susanne Hellwig, Alstom

4:00 - 4:20pm - Interview with Naren Brahme, Tata Technologies, Interviewer Dr. Harri Kulmala, DIMECC

4:20 - 4:40pm - Interview with Dr. Jari Hämäläinen, Kalmar (part of Cargotec), Interviewer Dr. Harri Kulmala, DIMECC

4:45 - 5:00pm - Plenary Closing Discussion