8. Fachkongress Composite Simulation

Germany, Fellbach

Join ESI's presentation on "Virtual design of SMC/GMT components: From process simulation to simulations of micro- and macromechanical structures" on February 4th / Session II Neue Forschungsergebnisse Material- und Mikrostrukturmodellierung / 11:55 am at the 8. Fachkongress Composite Simulation in Fellbach, Germany (Schwabenlandhalle) and learn more about:

- Automotive applications

- Molding Simulation

- Data Processing

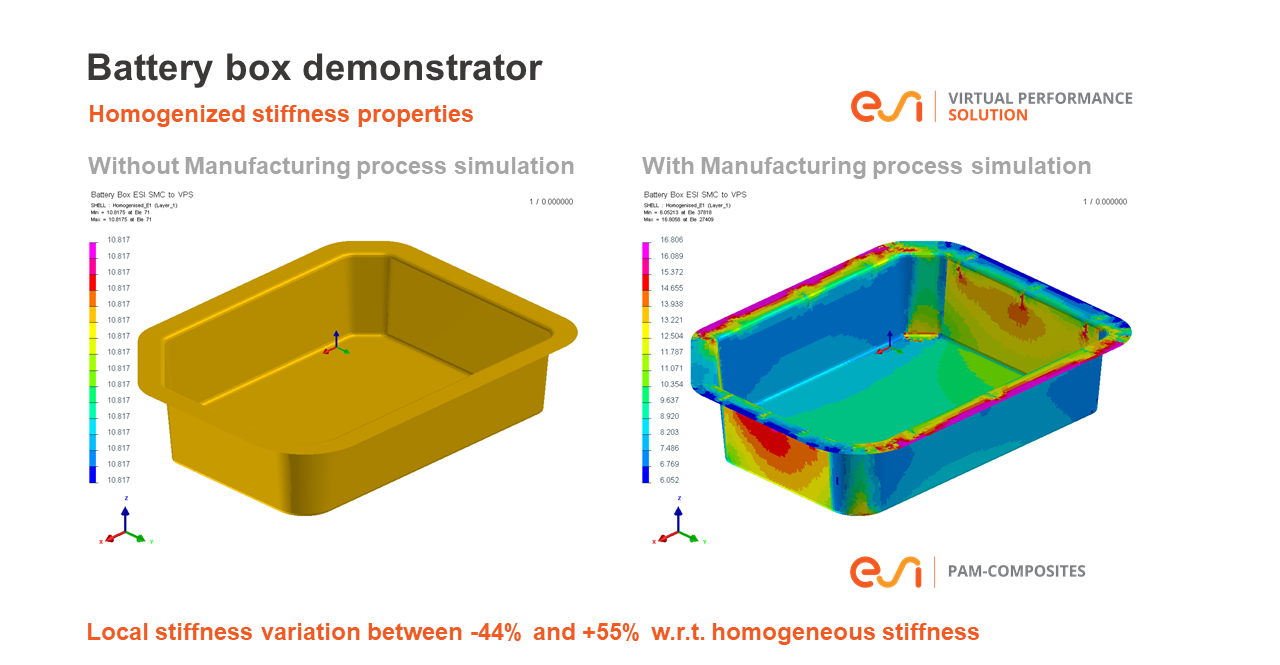

- Chaining Molding Simulation with VPS

- Structural analysis

- Demonstration

Visit us at ESI's booth to learn about the technical capabilities of Composites Manufacturing Simulation and Lightweight design with Virtual Performance Solution.

REQUEST A MEETING

Composites Manufacturing Simulation Software

Composite materials in engineering are gaining popularity with manufacturers due, in part, to their lightweight properties, strength, and durability. As with any industrial part or product, composites components must reach quality requirements and go through extensive testing to meet certification requirements, which usually happens late in the development cycle. When defects are found at this stage, they lead to additional time and costs and a delay in getting the product to market.

ESI PAM-COMPOSITES simulation software helps you target defects early in your composite product’s development cycle, when it’s easier to fine-tune the manufacturing process. With PAM-COMPOSITES, you can:

- Analyze and optimize individual manufacturing operations

- Link these operations by transferring material history from one operation to the next (change in fiber orientations, curing degree, temperature distribution)

- Correct, optimize or validate processes like draping, thermoforming, RTM, infusion or curing, to minimize manufacturing defects, insure reproducibility, and decrease development costs

Virtual Performance Solution

ESI’s flagship software is a unique solution allowing manufacturers to face emerging design challenges — including those related to lightweight, green and autonomous vehicles — while avoiding over-engineering. It enables design and simulation engineers to test rapidly their innovations on virtual prototypes, rather than real ones. Virtual Performance Solution (VPS) also offers a distinctive approach, allowing the virtual testing of product performance across multiple domains using a single core model.

Lightweight design with Virtual Performance Solution

If the potential of weight saving of advanced materials such as aluminum, high strength steels and composites is widely known, the production difficulties and costs prevent their unique usage in a complete vehicle structure. Utilizing the most appropriate material for each application and component reveals to be the most efficient lightweight strategy.