The vision of ESI Group, since its creation in 1973, is to solve real and practical engineering problems of several industries. These simulation solutions, based on the physics of materials, achieved a world-premiere in 1985: for the first time, a virtual crash test was performed for Volkswagen, paved the way to the massive adoption of virtual solutions in engineering processes and established new safety standards.

ESI Group now provides reliable and customized solutions anchored on predictive physics and virtual prototyping expertise to allow industries to take the right decisions at the right time, while managing their complexity.

A PERFORMANCE-ORIENTED VISION

The industrial market is deeply changing while new challenges appear for its players. Draconian regulations, disruptive technologies (Artificial Intelligence, Big Data, Internet of Things…), strong competition, shorten time to market, constrain industrial players to be more demanding in terms of quality, reliability, safety and production deadlines. This complexity gets even bolder with the ever-changing expectations of end-users who are no longer looking for products but for outcomes (flight hours instead of engines, kilowatts of electricity instead of wind turbines, etc.) and by the need to embrace environmentally friendly manufacturing and production processes. It’s setting the stage for a results-based economy that focuses on the final benefit for a customer or an operator, the KPIs more difficult to achieve, as success is measured by performance rather than by the product itself.

At ESI, we envision a world where Industry can commit to bold outcomes, addressing high stakes concerns – environmental impact, safety & comfort for consumers and workers, adaptable and sustainable business models.

Well-aware of these challenges, ESI’s commitment, as a leading innovator in Virtual Prototyping software and services, is to empower industrials with technological solutions that enable them to commit to outcomes.

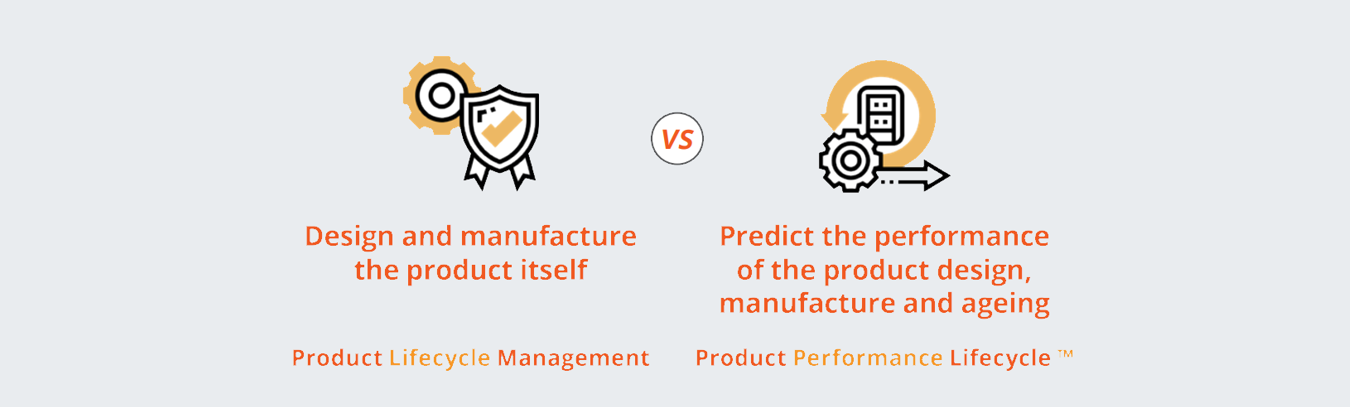

Coupled with the latest generation technologies, ESI’s solutions, addressing a complete industrial product development and manufacturing process, are radically transforming the traditional Product Lifecycle Management market by anchoring in the wider concept of the Product Performance Lifecycle, guaranteeing the operational performance of a product during its entire lifecycle, from design, manufacturing to disposal

Coupled with the latest generation technologies, ESI’s solutions, addressing a complete industrial product development and manufacturing process, are radically transforming the traditional Product Lifecycle Management market by anchoring in the wider concept of the Product Performance Lifecycle, guaranteeing the operational performance of a product during its entire lifecycle, from design, manufacturing to disposal

MAKE THE RIGHT DECISION AT THE RIGHT TIME

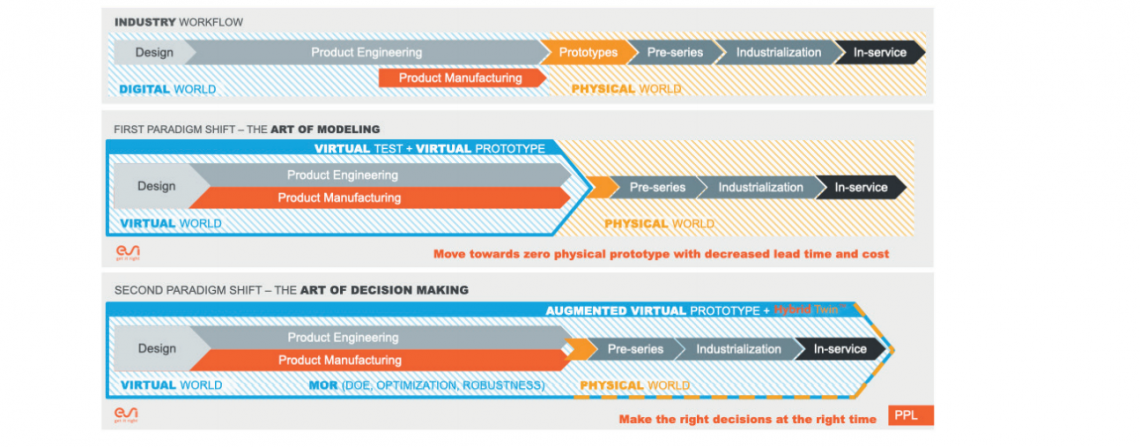

In the last century, the objective was simply to produce a product (cf. industry workflow below). Today, however, the focus is on product performance and not only on the product itself anymore. To achieve this performance goal, ESI Group is working on replicating the piece or product under study to make it " dialogue " with us in order to anticipate what will happen later-on.

This is the entry into the second paradigm shift: the art of decision making - we must predict quickly and well to enable making the right decisions at the right time.

In practice, how does it work? Engineers follow a product throughout its life from a replica (e.g.: replica of an airplane, nuclear reactor, wind turbine). To build such a replica - a Hybrid Twin - ESI Group combines computational science (mathematics) with data science (artificial intelligence) and virtual prototyping.

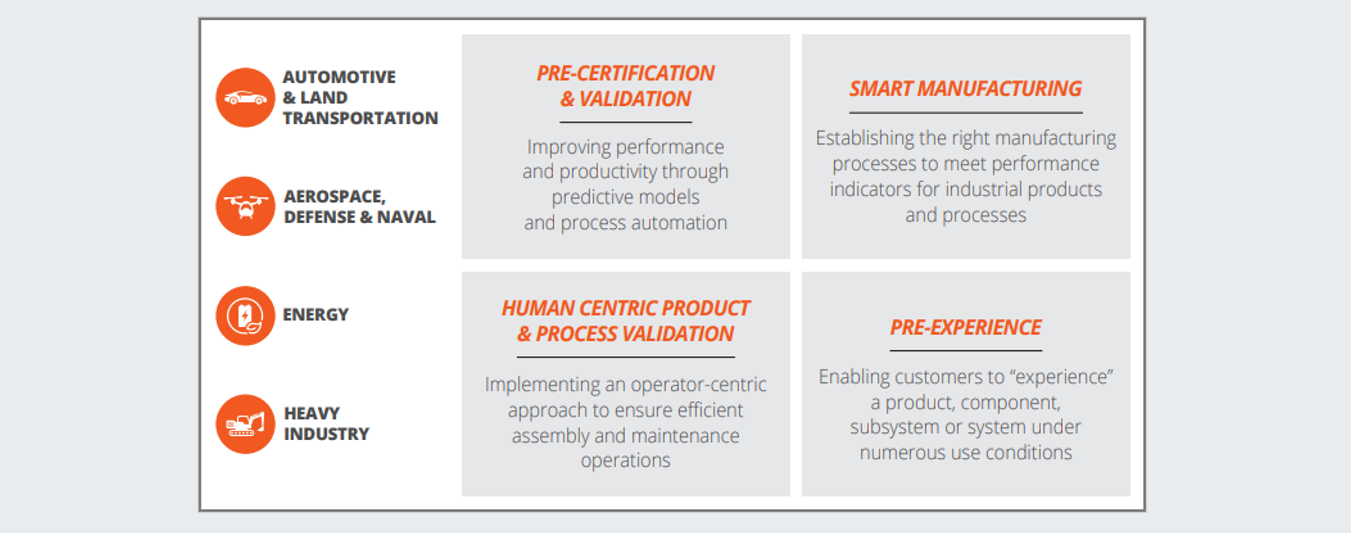

TO EMPOWER INDUSTRIAL PLAYERS WITH RESULT-ORIENTED SOLUTIONS

ESI’s offer is organized by industrial sector, including four main sectors. In order to adapt to the various industrial challenges and to better respond to the increased demands of its customers, ESI has organized its value proposition around four specific outcomes for customers, reflecting the value brought to its main markets:

MAKE THE DIFFERENCE WITH VIRTUAL PROTOTYPING

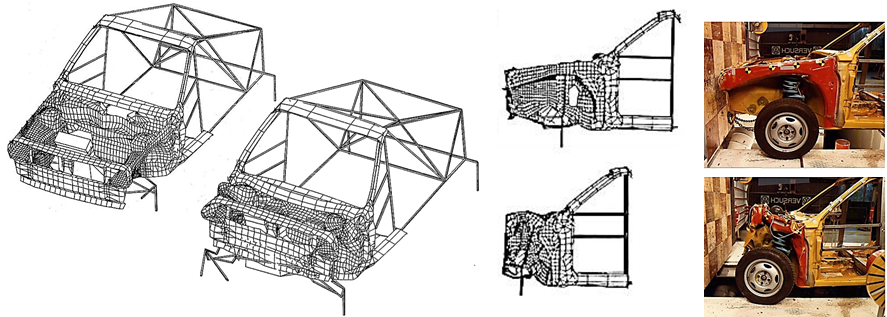

Virtual Prototyping is the freedom to displace physical tests and prototypes by virtually replicating product development, testing, and manufacturing with simulations.

Supplemented by advanced Virtual Reality, engineers experience in full immersion their latest designs prior to production. Our customers rely on Virtual Prototypes to digitally demonstrate reliability, safety, and energy efficiency upfront in the development cycle and to pre-certify their new technology right the first time.

In fact, Virtual Prototyping is part of an overarching and targeted approach known as predictive physics modeling, which addresses products’ operating performance throughout their complete lifecycle, from launch to withdrawal. Coupled with latest-generation technologies, ESI’s end-to-end solutions, which currently offers a comprehensive development and manufacturing process for industrial products, is revolutionizing the traditional Product Lifecycle Management (PLM) market.

ESI Group went the extra mile in providing engineers with the freedom to assess the ageing and behavior of a product at any stage and in any situation during its life. Equipped with smart sensor data collected from real life operations, our Virtual Prototype becomes artificially intelligent. ESI Group has created this unique solution which presents a double interest: firstly, in the management of products during their use but also in the manufacturing part (predict the behavior of products during the production phase and therefore make the right decisions at the right time on the manufacturing process). We call this a Hybrid Twin. The benefits for our customers are for example the use of predictive maintenance, high fidelity processes, interoperability between industrial players, the assessment of the impact on operational performance (e.g. reduce failures and risk) and the optimization of lifecycle costs.

Our customer stories are proven confirmation.